Horizontal fermentation tank is a kind of fertilizer composting equipment, which is widely used in the production of organic fertilizer. It can complete the harmless treatment process of organic waste in a short time. Such as chicken manure, cattle manure, mushroom waste, crop straw, etc. After composting, these materials will become more suitable for making organic fertilizer. And the horizontal fermentation tank has characteristics of covering less space, no pollution and can completely kill the pest eggs. Therefore, it is a wise choice for the breeding enterprises, recycling agriculture, and ecological agriculture to realize the utilization of waste resources.

Main Parameters

- Capacity: 5-50 m³

- Composting Time: 15-20 days

- Motor Power: 18.5 kw

- Equipment Material: Carbon steel, stainless steel

- Application: cow dung, chicken poop, pig manure, goat waste, bigas residue, straw, wine lees, sludge, sludge ,etc.

Why composting plays an important role in organic fertilizer production?

Organic waste, like chicken manure and cow dung, is absolutely an ideal material to prepare organic fertilizer. Because it contains rich organic matters and N, P, K, etc elements, which are necessary for the growth of crops. But if you use it as fertilizer directly, it will be harmful for crops and human beings. Because without composting, chicken manure and cow dung are smelly and contain a lot of pest eggs. Using them as fertilizer is easy to burn crop seedlings. Therefore, fermentation can greatly help you in these aspects. And horizontal fermenter is an excellent fertilizer machine for composting.

In a word, composting is necessary for the production of organic fertilizer. For this, horizontal fermentation pot is popular with organic fertilizer manufacturers.

Why horizontal fermentation tank is an excellent choice to compost organic waste?

There are many organic fertilizer composting machines in the market, so it is difficult to choose ideal one. But if you want to compost your fertilizer by in-vessel method. We recommend you to choose horizontal fermenter. It has many advantages as follows:

No pollution

The horizontal fermentation tank adopts the in-vessel fermentation method, which makes compost in a fully enclosed space. And it has a waste gas treatment system to treat waste gas and discharge it from the tank. So it will not cause secondary pollution.

Easy operated

This horizontal fermenter has a high degree of automation. So only one worker, you can control the whole fermentation process. During the process of composting, all steps are controlled automatically. Whether it is aeration, temperature controlling, mixing, deodorization or materials discharge.

Low operating cost

Horizontal fermentation pot adopts high-temperature aerobic fermentation method. It uses high-temperature biological bacteria technology to compost organic materials. Low energy consumption and low operating cost.

Long service life

All parts in contact with organic waste are made of 304 stainless steel. It has high performance of anti-corrosion. So the fermentation tank can provide you with service for a long time.

Wide adaptability

Horizontal fermentation pot has a layer of thermal insulation material. So it is less affected by the outside world and can help you compost organic fertilizer throughout the year.

Less space occupation

If you don’t have enough space for organic fertilizer composting. horizontal fermentation will be your optimal option. Its area is only one-thousandth of that of traditional fermentation.

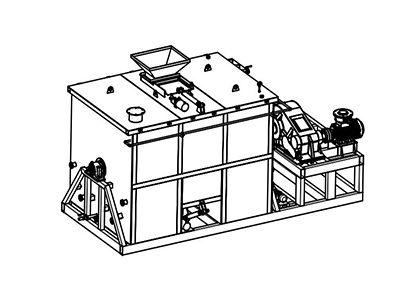

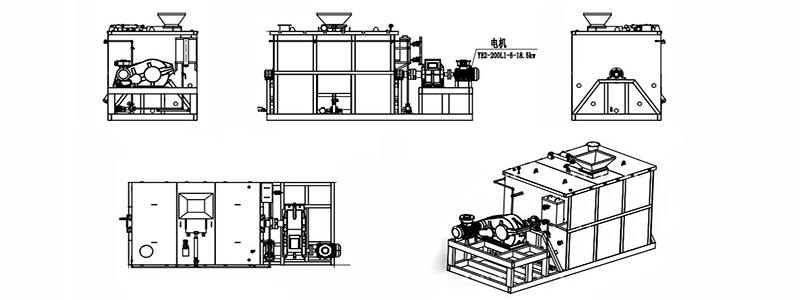

The structure of horizontal fermentation pot in SX fertilizer equipment factory

If you want to use a machine freely, you must know its structure. Of course, including horizontal fermentation tank. It consists of five parts as follows:

Tank

The tank body is mainly made of stainless steel plate with a thickness of 8 mm. It can effectively prevent the horizontal fermentation pot from animal manure corrosion. So you can use it for a longer time.

Main bracket

Because the bracket support the whole fertilizer composter. It needs to be sturdy and not easy to break. So our engineers use 200×100×4 mm rectangular tubes and 100×100×4 mm square tubes to make the main brackets. So the organic fertilizer composter can run stably.

Controller

The whole process of composting organic fertilizer by horizontal fermenter is controlled automatically. The controller is key to keeping the whole system running correctly.

Mixing shaft

Only the raw materials fully contact with oxygen, there will be a better fermentation. The mixing shaft is designed for this purpose. During poultry manure composting, it will blend the material to increase its breathability. So the fermented bacteria can work better. Then make organic materials in fully fermentation.

Temperature monitor

If you want to fully compost the raw material, you would better keep the temperature inside the tank at about 80℃. Then under the combined action of ventilation, oxygenation, and stirring, the temperature will drop to 55℃-60℃. This is the optimal temperature for material fermentation. Temperature monitor can help you know the temperature timely. So you can make adjustments without delay.

How horizontal fermenter works to process organic fertilizer?

First, putting the material to into the horizontal fermenter from the feed port through the belt conveyor. While feeding the materials, the main motor will start working and the motor speed reducer drives the main shaft to start stirring. At the same time, the spiral blades on the stirring shaft turn the raw materials, so that the materials are in full contact with the air. Then the aerobic fermentation starts.

Secondly, the heating system starts heating the heat transfer oil in the inter-layer of the fertilizer fermenter body. While heating, the temperature sensor will adjust the temperature of the body to a better fermentation temperature. After the horizontal composter finishes the fermentation, it will discharge the fermented raw materials from the discharge port. Then you can transfer the materials to the next process.

Differences between vertical fermentation pot and horizontal fermentation tank?

Expect horizontal fermentation tank, there is another in-vessel fermentation equipment we can provide you. It is vertical fermentation pot, which is similar to horizontal fermentation tank. But they are different in some aspects, you can choose according to your needs.

Appearance

he difference in appearance is obvious. Unlike vertical fermenter, which looks like a cylinder. Horizontal fermentation pot has a square shape as a whole.

Capacity

If you plan to buy a fermentation tank with a volume below 20 m³, we recommend you choose horizontal fermenter. But if you want to compost organic fertilizer with a volume more than 20 m³ once, it is better to buy vertical in-vessel fermenting equipment.

Price

The two are also different in price. Generally speaking, the price usually changes with the capacity of fertilizer composting machine. So horizontal fermenter price is lower than that of vertical fermentation pot. If your budget is limited and your materials volume is less than 20 m³. You can buy the horizontal fermentation tank. On the contrary, if you have enough budget and want to compost organic fertilizer in a large scale. Vertical fermenter is more suitable for you.

Space occupation

The space occupation is the other difference between them. If your workshop has enough space, horizontal fermentation tank will be your best choice. But if your factory is not too big, you can choose vertical fermentation pot.

How to be sure that the organic fertilizer materials are fully fermented?

If you want to make high quality organic fertilizer, you must know how to judge whether the raw material is fully fermented. There are three aspects you need to consider:

Temperature

During composting, the organic materials generally heat because of microbe reaction. So if the raw material temperature doesn’t rise again, you can discharge it from the horizontal fermenter. Then you can transport it to the next procedure.

Smell

In the horizontal fermentation tank, the microbes that make manure stink will be decomposed. So after composting, the organic waste no longer have irritating smell.

Appearance

Fermentation can make raw material become more fine and softer. Appearance is also an item where you can know whether the organic fertilizer materials are fully fermented.