Agriculture is the largest sector of the economy in Nigeria. So fertilizers are in high demand in Nigeria. And because of balanced nutrient content and good soil improvement effect of organic fertilizer, using it in organic farming has been a new development direction for agriculture in Nigeria. Therefore, many companies plan to invest in organic fertilizer factory. On 23rd August 2022, a customer from Nigeria inquired about how to start an organic fertilizer plant. Then after negotiation on details, we design a customized project for organic fertilizer production according to customer’s actual conditions. The following are the specific details of the communication in this case:

Main Paramters

- Country: Nigeria

- Capacity: 10 t/h

- Material: cow dung, chicken poop, pig manure

- Requirement: organic fertilizer granule making

- Solution: Rotary drum granulation line

How to design a project for the organic fertilizer factory?

This customer from Nigeria planned to start a factory for commercial organic fertilizer making. Do you know what we will consider when designing this organic fertilizer preparation line? In general, in the process organic fertilizer making project design, we need to focus on material, capacity, workshop area, budget and other actual conditions of your organic fertilizer production.

Nigeria Customer Requirements for Organic Fertilizer Making

- Material: cow dung, chicken poop, pig manure

- Capacity: 10 t/h

- Workshop: 5000 ㎡

- Requirement: organic fertilizer granule making

- Budget: $300,000

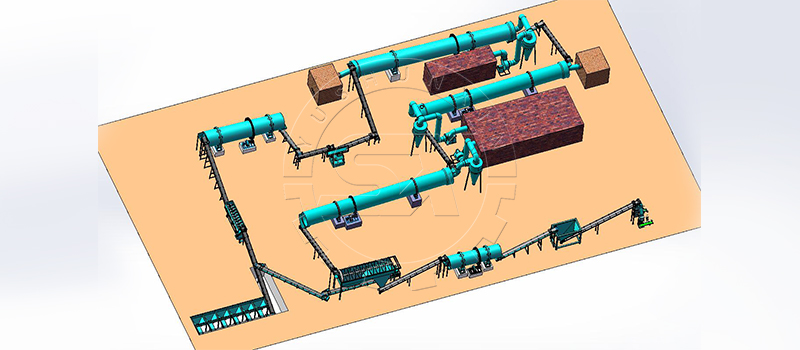

And after discussing details with our buyer, we sent an rotary drum fertilizer granulation line to him. It consists of a wheel type compost turner, a vertical crusher, a double shaft mixer, a rotary drum granulator, a rotary dryer, a rotary cooler, two fertilizer screeners and other auxiliary equipment.

Does the wheel type fertilizer compost turner require a human driver?

The Nigerian client wanted to buy an organic fertilizer composting system with a high degree of automation. Combining with the capacity he requires, we recommend the wheel type composter.

Because its maxium fertilizer composting span can reach 30 m, which can fully meet your 10 T/H organic fertilizer plant setup, and even scale enlarge latter. Moreover, it adopts fully automatic control system. So only employing a worker to check the fermentation status and operate the electric control cabinet, you can finish the whole aerobic fermentation process.

What granulation equipment is best to buy for 10 TPH organic fertilizer plant?

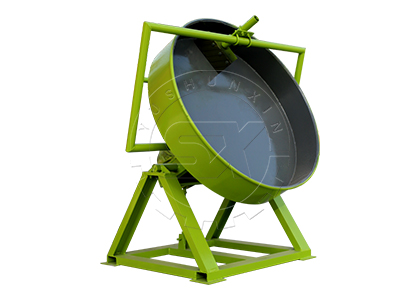

This client wanted to make organic fertilizer into granules with 10 t/h capacity. For this, pan pelleting machine and rotary drum granulator are both an ideal choice for organic fertilizer granulation. But they are different in several aspects.

First, they are different in granulator number. The former, whose capacity is 0.5-6 t/h, you need buy 2 sets for the organic fertilizer granule making. Meanwhile, the latter has a capacity of 1-30t/h and is an optimal option for making organic fertilizer in a large scale. In addition, the rotary drum granulation machine has a high erosion resistance because of rubber lining adding. Therefore, for this Nigerian customer, who planed to prepare 10 tons of granular organic fertilizer, we recommend him rotary drum pelletizer.

How much would it cost to start an organic fertilizer plant in Nigeria?

Finally, this client asked about the price of this project for organic fertilizer plant. Because the price of the fertilizer manufacturing line will change according to its configuration and capacity. So the pay of each customer is different.

But SX fertilizer equipment company will offer you high quality fertilizer processing machine at a favourable price. Because we have mature technology and years of experience in manufacturing of organic fertilizer equipment. And we are a source factory of fertilizer machine, which can devoid extra charge. In general, a 10 t/h organic fertilizer granulating line needs about $300,000.

The above are details about our communication with the customer from Nigeria. Except organic fertilizer plant equipment, we also can provide you with fertilizer production project designs for NPK fertilizer production, bulk blending fertilizer making, bio fertilizer manufacturing, etc. If you are interested in them, please contact us immediately.