How to make small scale composting business? There are various small scale compost machines for your choice in YUSHUUXIN. In addition, you can setup a small scale commercial compost system, which can help you improve the compost quality and speed up the compost making. And whether you want to compost chicken manure, cow dung or pig waste, it can fully meet your needs. Besides, if you want to expand the production scale later, you only need to replace some key equipment in the whole production line for that of a larger capacity.

Small Scale Composting Machine

- Capacity: 1-10 t/h

- Cost: $4,000-$80,000

- Composting Time: 15-20 days

- Equipment Types: trench / windrow / in-vessel

- Equipment Material: Carbon steel Q235, 16Mn, etc

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: animal manure, biogas residues, mushroom waste, etc

How to compost organic fertilizer faster?

Top 3 types of small scale composting machines in YUSHUNXIN

In YUSHUNXIN, there are many types of small compost machines for your choice. In terms of composting method, the small composting facilities can be divided into 3 types:

Fast In-vessel composting in a small quantiries

For small scale compost making, in-vessel compostor can decompose organic waste faster. Because, the organic materials will be fed into a full closed tank for fermentation. The composting environmental conditions including temperature, moisture, and aeration are automatically controlled. Therefore, the organic fertilizer fermentation tank can shorten the compost time to 10-15 days. For small scale in-vessel composting, we recommend you choose horizontal fermentation tank, which can dispose of 5-50 m³ organic waste a batch. And it can be customized according to your needs to small composting business. If you have any questions about this composting facility, just contact us freely.

| Equipment | Horizontal Fermentation Tank |

|---|---|

| Capacity (m³) | 5-50 |

| Motor Power (KW) | 18.5 |

| Heating Rod Power (K W) | 3*10 |

| Hot Oil Pump Power (KW) | 1.5 |

| Inlet Hydraulic Power Unit Power (KW) | 0.55 |

| Outlet Hydraulic Power Unit Power(KW) | 0.55 |

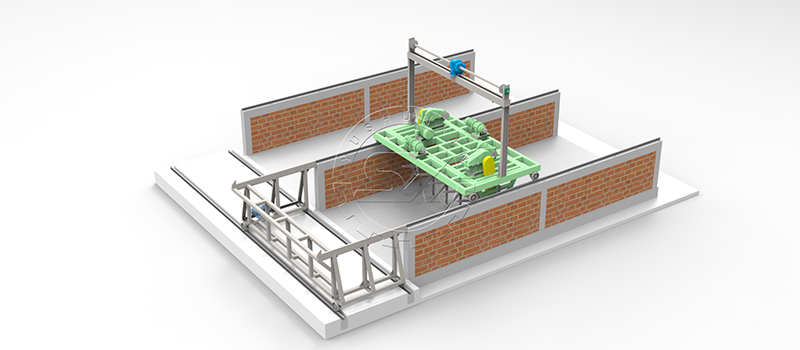

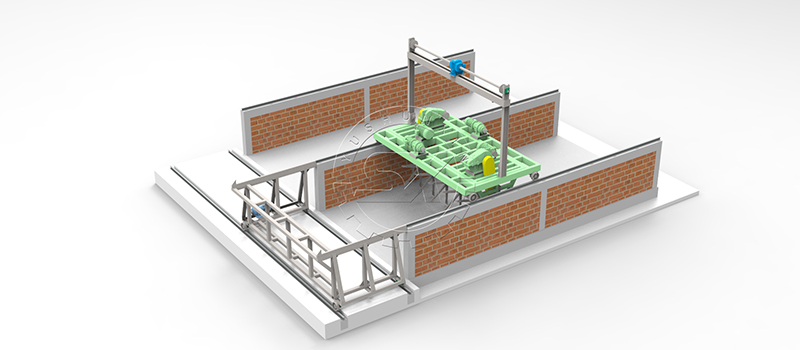

Economical Trench composting machines for small scale fermentation

In terms of cost of small scale composting, it is advisable to buy our trench type compost equipment. Because it has a favourable price. So, even you need to build some fermentation grooves in your small compost manufacturing plant, it is an economical choice. Moreover, it has an automatic electronic control system. only need to preset working model, industrial compost equipment can moving smoothly along the rails on the both sides of the grooves to help you turn the raw materials and transport the oxygen in it. Here, for small scale compost production, YUSHUNXIN can offer you groove type composter and chain plate type compost turner.

Groove type compost turner with high cost-effective

Groove type compost turning equipment is widely used in small scale fermentation process. The reason is that it has an economical price with a large capacity. Its price is $6, 500- $ 19,000, but the turning width is 2-5 m and the turning depth is 0.8-1.5 m. So it can turn more organic raw material to transport oxygen into it. This can greatly contributes to better fermentation. And with groove changing device, you can complete the groove changing quickly and easily.

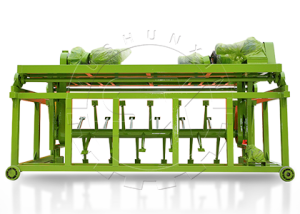

Chain plate type composter with adjustable speed system

When you need a fertilizer compost turner with adjustable walking speed, chain plate type compost turning machine is an excellent choice for you. It adopts variable frequency speed control system, which can change working speed flexibly according to the manure material resistance. So it can well adapt to the regulation of working load. Moreover, it can complete organic fertilizer fermentation better because of pallet design. The pallet design makes the material stay longer and disperse at a high position, so it can fully contact with oxygen and easily reduce moisture content.

| Equipment | Main motor(kw) | Moving motor(kw) | Turing width(mm) | Turing depth(mm) |

|---|---|---|---|---|

| Groove Type Compost Turner | 15-18.5*2 | 1.5 | 2500-5000 | 800-1500 |

| Chain Plate Compost Turner | 18.5*2 | 2.2*2 | 4000 | 1000-1800 |

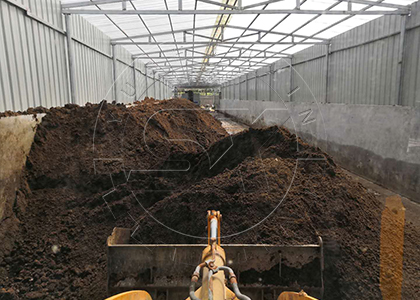

Mobile small scale windrow composting

In windrow composting system, organic waste is formed into long windrows to start small scale composting on the flat ground dirfectly. There is no fermentation groove needed and the windrow compost machine has flexible waking system. Therefore, you even can drive windrow compost facility to compost fertilizer in a small scale at any place. If you are more willing to use this method to start your small scale composting, SX will provide you with two types of windrow composters.

Moving type compost turner for low cost small scale windrow composting

When you want to start small scale windrow composting at a lower cost, moving type compost turner from SX is an excellent choice for you. A moving type windrow composter only needs $4,000-$1,200. Is composting efficiency lower? No. This machine can turn over 300-500 m³ of organic materials piles per hour. In addition, whether you want to use animal manure, sludge, agricultural waste or biogas residue as material, it fully meets your needs. It uses stirring teeth to turn these materials, which can make them fully contact with oxygen for better fermentation. Meanwhile, it will mix the sticky fermentation material, microbial fermentation agent and straw powder effectively. Moreover, it can move freely in the workshop and outdoors because of the unique four-wheel walking design. Therefore, with high working efficiency and low energy consumption, this type of compost turner is widely used in small farm composting systems.

Crawler type compost turner for small scale commercial composting over 500m³/h

If you plan to start a large scale fertilizer windrow composting, crawler type compost equipment is better. Its capacity is about 500-1500 m³/h. In your small scale composting system, turning width is about 2.4-3 m and stirring height is 0.8-1.5 m. Bur the length of the windrow is not limited and the section shape of the windrow can be trapezoid or triangle. Then, the whole body of crawler type compost machine should bestride the stacked windrows to do its work. At this moment, the rotary knives installed on a strong rotary drum under this turner machine can blend, loosen, and even move the piled compost. In this way, oxygen can come into the compost pile and speed up the fermentation process.

| Equipment | Turing width (mm) | Turing depth(mm) | Capacity (m³/h) | Model |

|---|---|---|---|---|

| Moving Type Windrow Compost Machine | 2000 | 600-800 | 300-500 | Diesel/Electrivity |

| Crawler Type Windrow Compost Machine | 2400-3000 | 600-1500 | 500-1500 | General/Hydraulic/ Driveless |

What is the windrows spacing in small windrow composting?

Generally speaking, the ideal pile height is between 4 and 8 feet, and the ideal pile width is between 14 and 16 feet. It will allow the compost pile large enough to generate sufficient heat and maintain temperatures, and small enough to allow oxygen to flow to the windrow’s core.

Contact us for your own small scale compost turner?

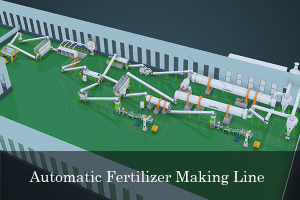

What kind of machine you need for setting up your small scale compost fertilizer plant?

if you want to make quality compost machine, you can setup a small scale composting system. Generally spealing, it contains processes of crushing, composting, screening and packaging final fertilizer . So, if you want to set up a small scale compost fertilizer plant, you need to equip with fertilizer crusher, 8composting machine, screener, and packing equipment.

The first step: Crushing

If you want to compost the raw materials quickly, crushing is an important step during the small scale composting process. Because during the crushing process, the fertilizer raw materials will be shredded into smaller particles. So composting materials have a bigger contact area with oxygen. This is greatly beneficial for aerobic fermentation of organic waste in small quantities. For this, our new type vertical crusher and semi-wet material crusher are both suitable for you. They can grind caked materials into fine powder without blocking.

The second step: Compost pile turning

Compost pile turning is the key step in the small scale composting process. And we recommend you use professional organic fertilizer compost turner. It can turn over the compost piles from time to time to let more oxygen into the piles. Then compost bacteria in manure will decompose organic matter and generate heat to kill harmful substances. Therefore, you can use organic waste as fertilizer safely. For small scale compost business, there are various composting machines for your choice. Including groove type compost turner, windrow compost tuning machine and in-vessel fermentation tank.

The third step: Sieving compost fertilizer

Screening is another important process in the small scale composting business. SX small scale screening equipment has a high screening efficiency for particle size less than 300 mm. During this process, fine powder compost will be separated from waste materials, such as stones, cigarette butts, branches, etc. So, it can help you finish the screening work quickly. So you can prepare higher purity compost fertilizer.

The final step: Packaging compost fertilizer powder

In order to make it more convenient to transport, store and use, finally, you need to pack compost powder to sell. However, manual bagging will take a long time, we recommend use automatic bagging equipment. It not only has a quantitative precision of 2 ‰, but also various types for your choice.

How to run a small scale composting business with low cost?

If you want to start a small scale composting business in your country, SX can help you to start it with the low budget. We can decrease your cost in the following aspects:

- Ideal equipment price: We are source factory of fertilizer processing equipment. There is no extra charge during sale. So we can provide you with an ideal price.

- Low maintenance cost: We have advanced technology in the manufacturing of fertilizer equipment. So our composting euipment has high quality and can operate for a long time. And we can provide you with guidance on how to operate it correctly and how to maintain it. So you don’t need to replace it in a short time.

- Resonable project design: We can design your small scale organic fertilizer composting project according to your material, capacity, budget. etc. If your budget is not enough, we will recommend you simpler production line and equipment with small capacity and low price.

In addition, if you want to further make compost into organic fertilizer, we alos can offer you best solutions for small scale organic fertilizer production line.

Is there operational small scale composting system all the world?

Of course. Serveral days ago, the customer from Philippines gave us a feedback that the small scale commercial fertilizer composting line has helped him earn back his principal within only 6 months.

- Country: Philippines

- Material: cow manure

- Moisture: 70%

- Capacity: manure from 1000 cows

- Requirement: only compost machine

- Solution: groove type compost turner