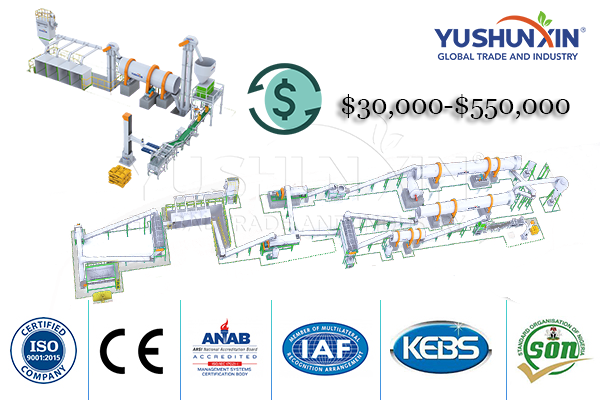

If you plan to setup a fertilizer making plant, cost is an item you must focuse on. But, it is usually not fixed. The fertilizer manufacturing plant cost is closely related to the fertilizer types, method employment and equipment choosing, etc. As a professional fertilizer equipment manufacturer, YUSHUNXIN designs fertilizer production lines with different prices for your choice. In addition, if you have any special requirements, we also can provide customized plan for your fertilizer plant according to budget requirements.

Main Parameters

- [capacity] 1-20 t/h

- [Cost] $20,000-$550,000

- [Fertilizer shape] powdery/granular/liquid

- [Products] Organic fertilizer, compound fertilier, npk fertilizer, solid fertilizer, liquid fertilizer, etc

- [Application Material] Animal manure, biogas waste, humic acid, bentonite, sugar factory waste, straw, NPK, etc

What is the price of organic fertilizer making line machines?

Organic fertilizer is a kind of fertilizer made from animal manure, industrial waste, agricultural litter, which contain rich nutrients. Such as nitrogen, phosphorus and potassium. Usually, you can process organic ferilizer into 2 forms. Powder and granule. Correspondingly, YUSHUNXIN fertilizer equipment company design powder organic compost making line and organic fertilizer granulation plan. Because of different configuration, the organic fertilizer manufacturing line price is as follows:

Granular organic fertilizer making line cost

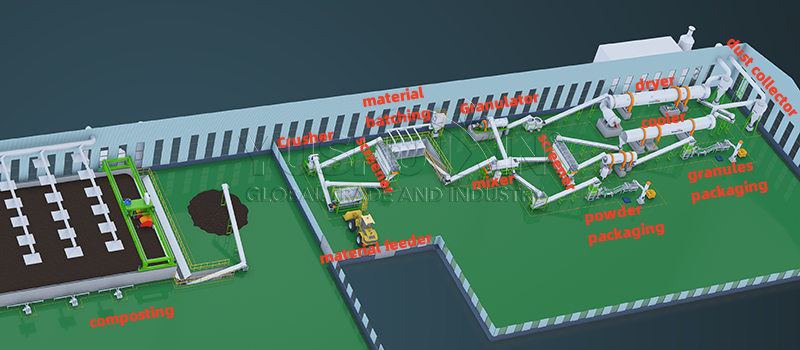

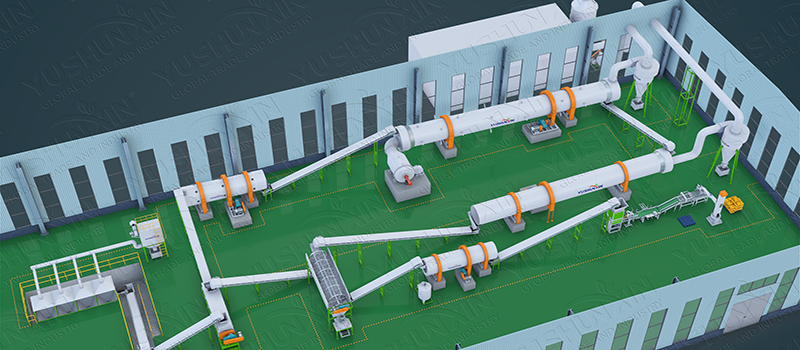

Generally, the cost of organic fertilizer granule production is closely related to the capacity. A 1-5 t/h small scale organic fertilizer making line costs$100,000-$150,000; Starting a 5-10 t/h fertilizer plant setup needs $150,000-$350,000; The price of a 10-20 t/h granular fertilizer manufacturing system is $350,000-$500,000. If you plan to prepare quality organic fertilizer and have enough budget, we recommend you to by an organic fertilizer granulation line. Making organic waste into fertilizer pellet will bring stable nutrient content, longer storage time and better fertilizer effects. In YUSHUNXIN, A complete granular fertilizer making line consists of many fertilizer processing machines. Composting equipment, batching equipment, crusher, mixer, granulator, dryer, cooler, screener, coating machine and packing equipment.

| Capacity | Cost |

|---|---|

| 1-5 t/h | $100,000-$150,000 |

| 5-10 t/h | $150,000-$350,000 |

| 10-20 t/h | $350,000-$550,000 |

Powdery fertilizer production line price

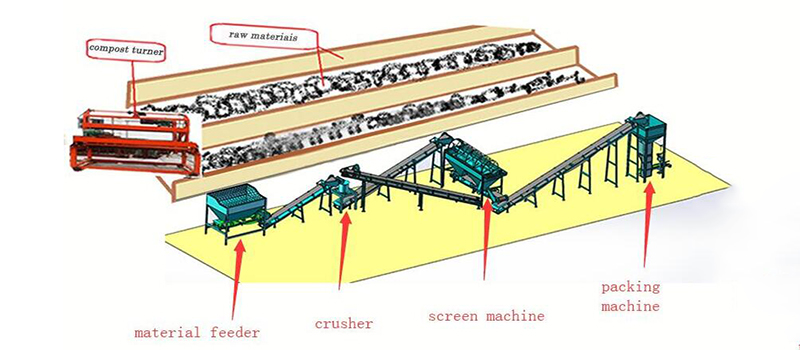

If you want to process animal manure into organic fertilizer at a low cost, you can choose this powdery organic fertilizer production line. It is designed to turn raw materials into powdery organic fertilizer. So it only contains compost machine, feeder, crusher, screening machine, packing equipment and belt convey machine. It is the simplest production line of organic fertilizer. Only half of the equipment of the granular fertilizer production line. Less equipment also suggests less space occupation. So it can not only reduce your cost on organic fertilizer equipment, but also on workshop area. Commonly, you only need to prepare $20,000-$90,000 for it.

| Capacity | Cost |

|---|---|

| 1-5 t/h | $20,000-$45,000 |

| 5-10 t/h | $40,000-$60,000 |

| 10-20 t/h | $60,000-$90,000 |

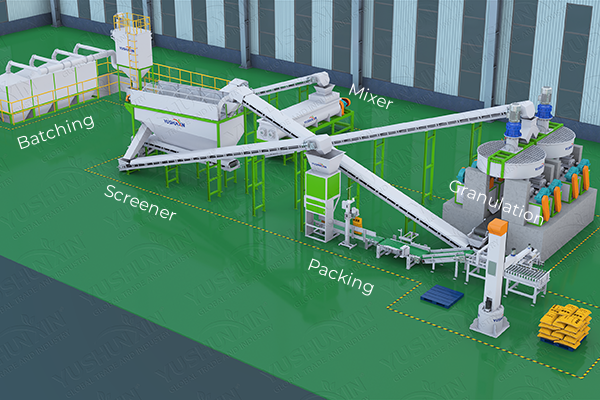

How much does a compound fertilizer granule production line cost?

If you want to start a compound fertilizer production, especially when you setup a NPK fertilizer making line, there are 2 shapes of materials for your choice. Powder and granule. Generally speaking, the price of powdery compound materials is lower than that of granular ones. However, if you want to turn powdery raw materials into the required granule compound fertilizer. You need to complete a process of multiple procedures. But if you use pellet materials, only 3 steps, you can get the final fertilizer.

Compound NPK powder to granules project budget

The process of making chemical powder into compound fertilizer pellet is similar with organic fertilizer granulation line. But it has no need to dewatering and composting. Therefore, it has a lower cost than the project of making organic waste fertilizer pellets. The cost of a complete compound NPK fertilizer production line is $80,000-$400,000.

NPK Powder Granulation Line

- Cpacity: 1-20 t/h

- Material: Chemical powder, including urea, MAP, MOP, SOA, DAP, SOP, KCl, etc

- Design: Batching equipment, crusher, mixer, granulator, dryer, cooler, screener, coating machine and packing equipment, etc

- Cost: $80,000-$400,000

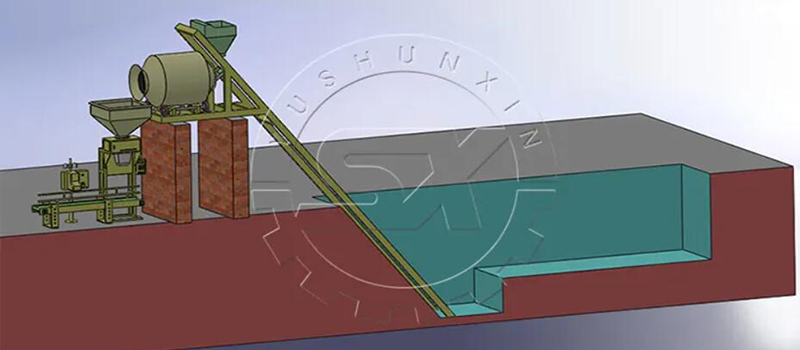

BB fertilizer preparation line budget

Is there a low cost production line for compound NPK fertilizer? Of course. Our BB fertilizer preparation line is on sale. It can help you finish compound fertilizer manufacturing in three steps. Batching, mixing and packing. But its capacity can reach 3-50 t/h. Therefore, it can fully meet your requirements, whether you want to manufacture fertilizer in a large, medium or large scale. But for this production line, you only need to invest $10,000-$150,000 in it.

BB Fertilizer Making System

- Cpacity: 3-50 t/h

- Material: Chemical pellets, including urea, MAP, MOP, SOA, DAP, SOP, KCl, etc

- Design: Batching machine, BB fertilizer mixer and packing equipment.

- Cost: $10,000-$150,000

Moreover, we also can offer you fertilizer making plan which use solid + liquid materials, such as SSP fertilizer making. If you need more precise quote of NPK fertilizer making lines, welcome to contact us directly.

Is there a low investment business plan for fertilizer pellets making?

Of course. As a professional fertilizer equipment manufacturer, we will design fertilizer granules making plans according to your budget. If you want to make organic and compound fertilizer at a lower investment, there are two tips for you.

Buy Key machines for fertilizer pelleting

For one thing, you can buy several key machines for organic and compound fertilizer granules preparation. Such as crusher, granulator, dryer and bagging machine. And its smallest capacity model price is only $20,000-$80,000. Later, if you want to enlarge your the scale and quality of your fertilizer making line, only need to add correspond machines. Such as batching machine, mixer, screener, coating equipment and so on.

Buy roller dry granulation line

For another, you can buy the fertilizer granulation system with a lower cost. For example, if you want to make NPK pellets in a small scale, double roller granulation line is the best choice. Because of dry granulation method employment, it don’t need to buy dryer and cooler for fertilizer granules production. Therefore, it can save money on dryer and cooler buying and fuel consumption.

What is the land cost to build a fertilizer manufacturing plant?

Besides the expense on fertilizer machines purchasing, a large part of fertilizer manufacturing plant costs is land investment. In general, it is closely related to two factors. One is the area needed of your fertilizer making plant, another is the land rent or pricing in your country. Here, YUSHUNXIN will offer you the land occupation details for the designed fertilizer making plant layout. Taking organic fertilizer making as example (for reference).

Powdery fertilizer making line area

| Capacity (T/H) | Area (㎡) |

|---|---|

| 1-3 | 800 |

| 5 | 1500 |

| 10 | 3000 |

| 20 | 5000 |

Fertilizer granulation system land

| Capacity (T/H) | Area (㎡) |

|---|---|

| 1-3 | 2000 |

| 5 | 4500 |

| 10 | 5500 |

| 20 | 10000 |

But, if you need land cost for your own fertilizer plant setup, welcome to contact us for details. Only send us your local land rent or pricing, we will offer your the answer after deciding the fertilizer preparation plan.

How much area doese a 30 t/h fertilizer making line needed?

How much energy consumption of fertilizer production line?

The fertilizer production energy consumption can vary significantly depending on the scale and technology. Typically, small to medium-sized operations may consume between 100 to 500 kwh per ton of fertilizer produced. Larger, more efficient YUSHUNXIN fertilizer making facilities might have lower energy consumption rates due to advanced equipment and optimized processes. So, you can establish a fertilizer manufacturing plant at a lower investment. If you need more details about the energy consumption of fertilizer making machine you plan to buy, welcome to contact us now!

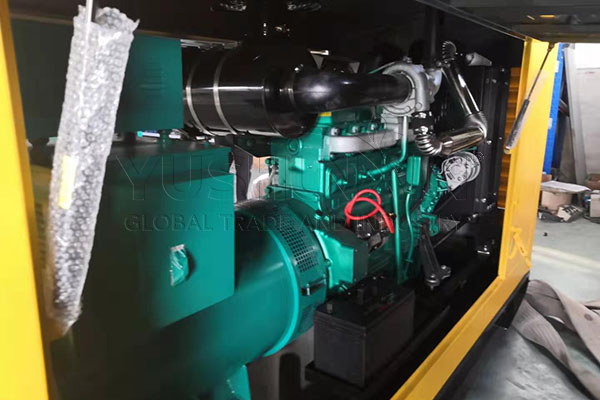

Is there solution for fertilizer machine electricity?

Of course. For one thing, we can offer you customized fertilizer machines. Such as fertilizer diesel composting equipment, fertilizer granulators and so on. For another, we also have power generators for your fertilizer manufacturing plant. It will use diesel as fuel to generate enough electricity for your fertilizer making machines. In addition, in order to fully meet your requirements for fertilizer preparation, we also design mobile power generator for you.

4 Tips to establish an economical fertilizer manufacturing plant?

There are many factors that affect the cost of establishing a fertilizer factory. So besides the choice of types fertilizer production line, you can also reduce the cost of building your fertilizer plant from these aspects.

Find reliable Equipment manufacturer

Choosing a reliable equipment manufacturer is important to build fertilizer manufacturing plant with low cost. For this, SX is an excellent choice for you. As a professional fertilizer equipment factory, SX has advanced technology and nearly 20 years experience in this field. So we can provide you with high quality machine and economical price. In addition, we can offer you guidance on installation and maintenance to prolong its service life. So in long terms, it only needs a low investment.

High quality Equipment Purchasing

High quality fertilizer processing machines usually can be used for a long time. So you can spend less on changing broken fertilizer equipment. For this, YUSHUNXIN fertilizer equipment is your ideal choice. Because it is mainly made of high strength materials and all areas in contact with materials are made of corrosion resistant steel. And we can provide guidance on how to operate it correctly and how to maintain it. These can prolong the service life of your fertilizer machine.

Reasonable design for fertilizer plant layout

Reasonable layout also can reduce your fertilizer manufacturing plant cost. We can provide you with a free project design according to the actual situation of your project. You only need to tell us your materials, capacity, plant area and budget. We can offer you free process design drawing, reasonable configuration plan, forward guidance according to your requirements.

Buy from source fertilizer machines factory

Where to buy is also a factor which influences your cost. The prices of buying fertilizer equipment online or offline, from distributor or source factory are different. It is no doubt that buying equipment from source factory is more economical. So SX is an optimal option for you. Because it is a source factory for fertilizer processing equipment and there is no extra charge.

Here, YUSHUNXIN is an ideal choice for you. We are a turnkey fertilizer plant machine manufacturer, which can offer you not only offer quality fertilizer machines at a source price, but also services of fertilizer making system design, testing, intallation, operation training, etc. Come to get your customized fertilizer business plan now!

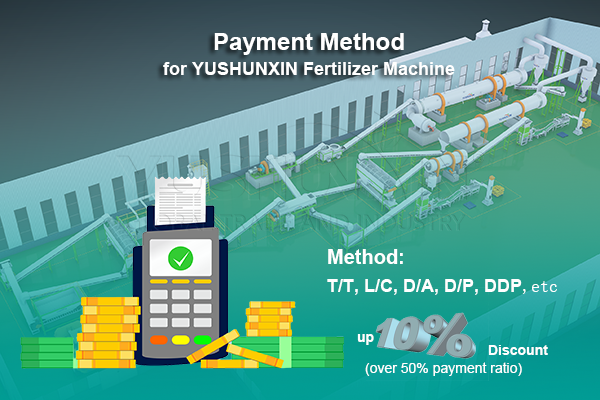

Which payment method is better when importing a YUSHUNXIN fertilizer making line?

When importing a YUSHUNXIN fertilizer manufacturing line, you have access to a variety of flexible and secure payment methods. Whether it is T/T (Telegraphic Transfer), L/C (Letter of Credit), D/P (Documents Against Payment) or D/A (Documents Against Acceptance), you can choose freely according to your financial setup.

In addition to traditional options, YUSHUNXIN also supports DDP (Delivered Duty Paid) service. If you prefer a hassle-free process and want to receive the equipment directly at your doorstep, choosing DDP terms can save you the effort of handling customs clearance and logistics. This is ideal for those who are first-time fertilizer equipment importers or lacking import experience.

Regarding the ratio of the YUSHUNXIN fertilizer equipment payment, a 50% down payment is recommended. With the remaining 50% settled before shipment or upon delivery, depending on your chosen terms. What’s more, early or full payment may qualify you for additional discounts—with savings of up to 10% off the total price of your organic or fertilizer machines. This gives you not only flexible payment but also cost efficiency and peace of mind.