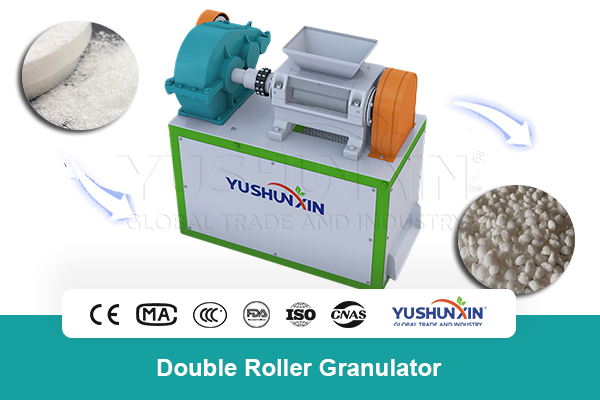

The double roller extrusion granulator is a hot selling equipment for making fertilizer into granules. Both for compound fertilizer production and organic fertilizer making. Because it adopts dry granulation method, which can produce fertilizer pellets without drying. The powder material is rolled and formed into fertilizer granules at one time, so it is an ideal choice for industrial fertilizer granulation plants. In addition, YUSHUNXIN double roller pelletizer has features of longer service life, high granulation rate, wide applications, etc.

Main Parameters

- Capacity: 1-4 t/h

- Feeding moiture: 5%-20%

- Granule Size: 3-10 mm

- Granulation rate: 97%

- Equipment material: Carbon steel Q235 + 20CrMnTi or 4Cr13

- Application: Making granule from powdery dried manure, nitrigen fertilizer, phosphate fertilizer, bentonite, industrial salt, etc

What method does double roller press granulation adopts?

YUSHUNXIN double roller press granulator adopts extruding granulation, which is also known dry granulation method. As the name suggests, it mainly relies on the physical extrusion force between the rollers to press fertilizer powder into granules. There is nearly no water involved.

The function of extrusion is to displace the air between particles and make the distance between particles close enough to generate attractive forces. Such as van der Waals forces, adsorption forces, crystal bridges, and inline connections, which can combine the particles together. In this way, you can directly turn dry powder into granules without adding additives (like water) and produce granules at the room temperature without drying. So it can provide you a fertilizer granulation technology with simpler process and lower energy consumption.

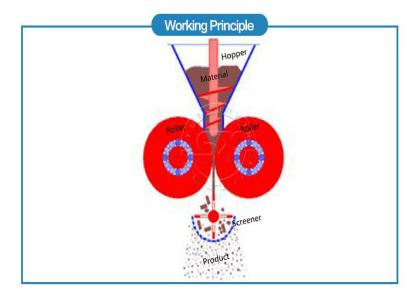

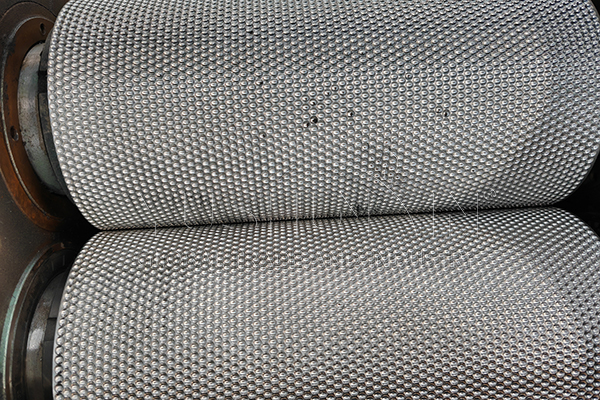

How does the double roller granulator work in your fertilizer granules production?

It is necessary for you to understand the working process of double roller granulator, if you want to prepare required fertilizer granules efficiently. In general, it contains 4 parts:

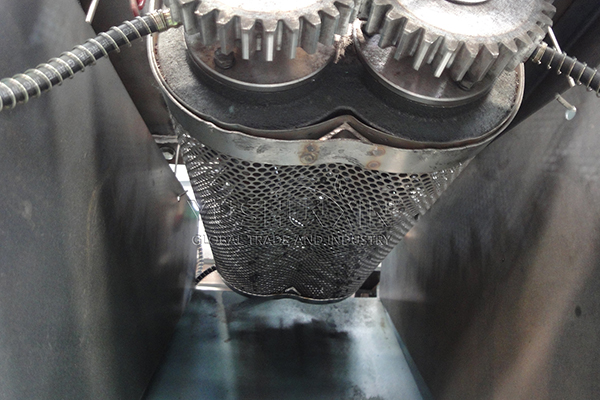

- First, when it starts to granulate fertilizer material, electromotor will drive the belt pulley. Then the belt is transmitted to the driving shaft by the speed reducer. So the driving shaft will operate synchronously with the passive shaft, which makes the double roller pellet mill start working.

- Then, feeding the powder material to the top hopper of the fertilizer granulation machine. The roller sheets will rotate relative to each other. The dry material will agglomerate and becomes a dense and hard mass (cake) under pressure.

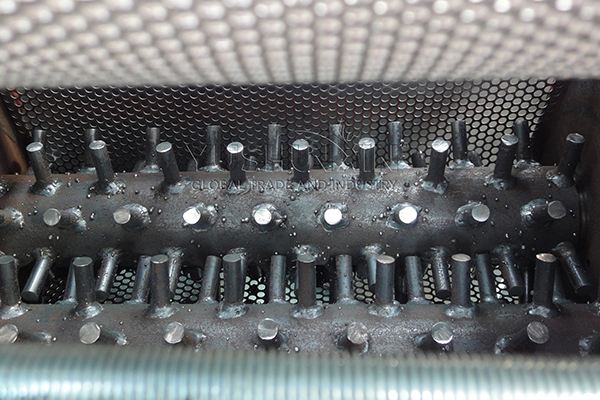

- Next, there are a pair of stirring shafts to break down the pressed fertilizer cake into single granular fertilizer. This is the final fertilizer pellets you plan to produce.

- In addition, to endure the fertilizer granulation cake is fully dispersed, we especially equip the double roller extrusion machine with a screen. Which only allows the single granulated fertilizer to pass through.

Get more details of double roller granulation machine!

What kind of fertilizer granules can double roller pelletizer process?

When you want to buy a proper fertilizer granulating machine, it is necessary to know what materials can the machine dispose of? Generally, the roller extrusion granulator can process many kinds of materials, which can be divided into 2 parts.

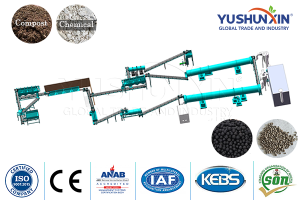

Compound fertilizer granules production

Initially, the double roller extrusion granulator is dsigned for making chemical fertilizer pellets. Therefore, it is suitable for zinc sulfate, potassium sulphate (SOP), potassium chloride, ammonia chloride, ammonia sulfate, magnesium sulfate, sodium chloride, etc

Organic fertilizer pellets making

But in 2010, YUSHUNXIN upgraded the roller extrusion pellet machine. So, now, it can also make fertilizer granules from organic compost. Whether it is chicken manure compost or cow dung compost, etc. But, because of dry granulation employment, your material water content must be lower than 20% before fed into the roller extrusion machine.

Can the roller press machine granulate phosphate rock powder?

Of course. As mentioned above, if keeping the moisture of raw materials at 5%-20%, double roller granulating machine can make granules from almost all powder materials. Therefore, it is also an ideal choice for phosphate fertilizer granule making, snow melt agent granulation, bentonite pellets production, etc.

Get more details of double roller granulation machine!

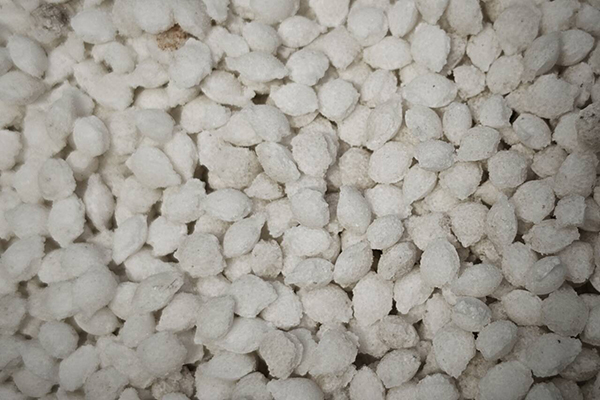

How about the fertilizer granules produced by double roller press granulator

If you want to know the quality of a granulator or whether it is suitable for you, one of the most direct methods is to see whether the finished pellets meet your needs. In general, double roller extrusion granulator can produce fertilizer granules with features as follows:

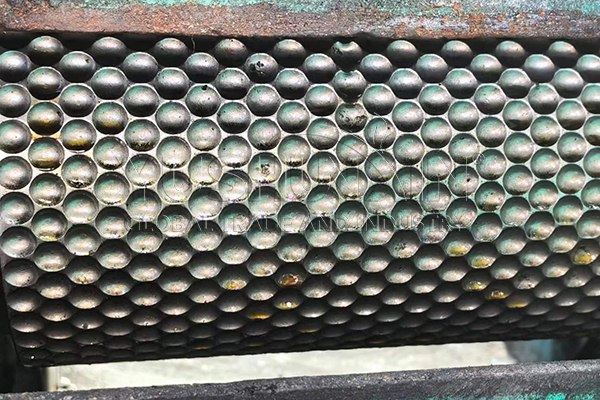

3-10 mm size

In general, the granulated fertilizer size depend on the size of ball sockets on roller sheets. Here, with YUSHUNXIN roller sheets, you can choose to prepare fertilizer pellets from 3mm to 10 mm freely.

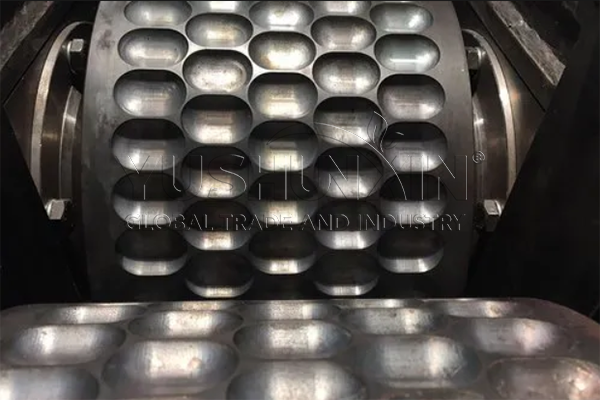

Various shape

Besides size, we also can offer you roller sheets with different shape ball sockets. So, besides flat ball shape, you can produce fertilizer particles with pillow shape, oval, square bar shape, stick shape, walnut shape, etc.

High hardness 15-20 N

In addition, because of the dry extrusion granulation method employment, the granular fertilizer produced by roller granulator has a high hardness – 15-20 N

Long storage time

Finally, because of high hardness and low moisture, it has a lower possibility of materials sticking and caking, and is convenient for storage and shipment.

If granules produced by the granulator can meet your needs, it is your ideal granulating machine.

Get more details of double roller granulation machine!

3 Advantages of double roller extrusion granulator from SX fertilizer machinery

With the development of technology, there are various fertilizer granulating machines on the market, each has its own advantages to attract customers. So, why double roller extrusion granulator is an ideal choice for you? There are 5 reasons as follows:

95% Granulation rate

It can produce particles at the room temperature without drying and form them at one time. Therefore, this compound fertilizer granulating machine can granulate faster and its granulation rate is as high as 90% or more.

1-4 t/h Various capacities

In order to fully meet your requirements of different capacities of fertilizer granule manufacturing, we especially design various models double roller pellet machines. Including the 1t/h, 1.5 t/h, 2t/h, 2.5t/h, 3t/h and 4t/h.

Low energy consumption

For one thing, as mentioned above, there is no subsequent drying is required. Therefore, you can save the consumption of fuel like coal, biomass pellets, gas, etc. For another, the motor power of the maximum capacity one is only 37 kw. Which is far lower than other fertilizer pelletizers. So, its electricity consumption is also low.

Technical parameters of SX double roller granulator

| Model | Power (kw) | Granule Diameter (mm) | Roller Sheet Size (mm) | Dimensions (mm) |

|---|---|---|---|---|

| SXDG-1T | 15 | 3-10 | 150×220 | 1450×800×1450 |

| SXDG-1.5 T | 18.5 | 3-10 | 150×300 | 1450×850×1500 |

| SXDG-2T | 22 | 3-10 | 185×300 | 1630×850×1650 |

| SXDG-2.5T | 22 | 3-10 | 245×220 | 1700×1000×1670 |

| SXDG-3T | 30 | 3-10 | 200×400 | 1960×980×1760 |

| SXDG-4T | 37 | 3-10 | 250×400 | 1960×980×1760 |

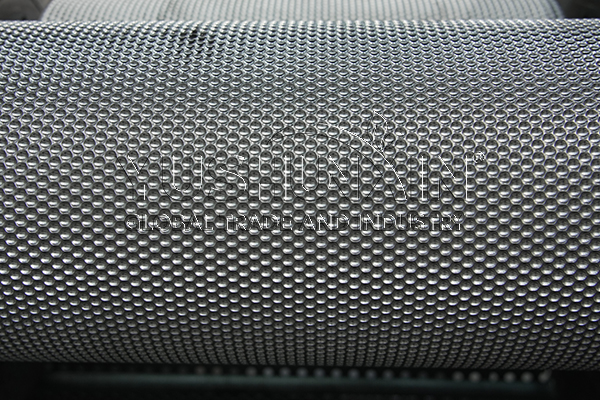

How long can double roller pressing granulator work?

How long can double roller pressing granulator work is another touchstone for the quality of a fertilizer pelletizer. And it is closely related to the double roller pellet machine manufacturing materials. In general, YUSHUNXIN double roller pressing granulator is made of 3 types of material.

- The main body material usually adopts high quality boiler steel Q235, which has characteristic of good welding performance and certain alkali corrosion resistance and oxidation resistance.

- For the roller sheets material, you can choose to use 20CrMnTi or 4Cr13 stainless steel according to your needs. The former has an economical price, the latter has a better performance in erosion-resistance.

In general, the machine can work 8-10 hours per day and provide service for several decades years. But the roller sheet is a wearing part, you need to change it every six months to one year. You need to pay attention to regular maintenance. Proper maintenance can prolong its service life.

How to maintain double roller extrusion granulator?

Maintaining your machine in the correct way can prolong its service life. Following methods are our engineers provide for you to maintain your double roller extrusion granulator:

- You best start machine without load. It is strictly forbidden to start with material.

- Don’t add the material with iron. It will break the axle

- Apply lubricating grease to the gears before starting the machine.

- Apply lubricating grease to the chain and sprocket every 7 days.

- Replace the new lubricating greaseof bearing seat every three months.

- Gear oil is necessary before reducer starts working. You need replace the gear oil every four months.

How to adjust double roller extrusion granulator to improve fertilizer quality?

In the granulation process of using the double-roll granulator, sometimes the particles are not spherical or the powder leaks too much. At that time, you can adjust these two parts of the double roller extrusion granulator to improve fertilizer quality.

Gap between the rollers adjustment

In the process of fertilizer production, sometimes it is necessary to increase the output or bite angle. At this time, you need to increase the distance between the two compression shafts. Then the distance between the driving shaft and the passive shaft becomes bigger. The steps are as follows:

- Stop the machine and remove the frame above the two bearing seats.

- Adjust the adjustment plate between the two bearing seats to the required thickness.

- The distance between the two rollers cannot make the wheels collide. So you need to keep the minimum between 0.3-1 mm.

Alignment of ball socket

The ball socket is contist of the pits on the surface of the main roller. So if you want to improve fertilizer quality, you must pay attention to axial alignment and circumferential alignment.

The axial alignment has been adjusted during installation

Generally speaking, the possibility of adjustment is not large. If you need to adjust it, you can tighten or loosen the glands on both sides of the passive bearing seat, so that the dislocated sleeve can move and correspond to the active shaft.

The steps of circumferential alignment

First, you should loosen the 6 connecting bolts of the driven gear and the adjustment sleeve, so that they can slightly disengage with each other. Then you can correct the circumferential direction by tightening or loosening the two adjustment bolts with a hand wrench. In addition, our engineers have already thought that customers may need to adjust the ball socket when designing the roller granulator. Therefore, they have reserved sufficient adjustment distance. So the dislocation can be adjusted no matter how much the dislocation is. Finally, you need to test the adjustment effect. Because the ball socket is too small, you can place a carton board between the two rollers during testing. After rolling, you can know whether the adjustment has achieved the purpose by seeing it. After alignment, you can tighten the 8 connecting bolts.

Besides, there are also many other fertilizer granulation machines for your choice. Like economical disc pelletizer, large capacity rotary drum granulator, new type organic fertilizer granulator for hard round fertilizer making, etc. Welcome to contact us for the best fertilizer pelleting equipment for you!