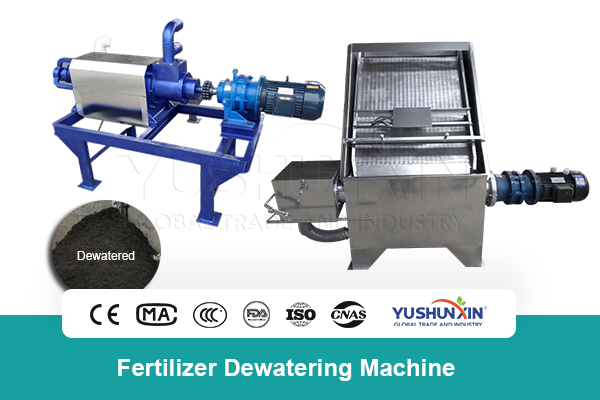

Whether you want to make manure into fertilizer or just dispose of manure waste in farm, a manure dewatering machine is an good partner. It can help you remove lots of water in manure quickly. After dewatering, you can get dry manure with only 30% moisture content. Here, YUSHUNXIN designs 3 types solid-liquid separator for manure drying. They are suitable for process manure with water content over 50% in 1-20 t/h easily. Come to get the best one for you now!

Main Parameters

- Capacity: 10-40 m³/h

- Feeding Moisture: over 50%

- Dewatered Moisture: 30%

- Power:4-5.5 kw

- Cost: $2,000-$8,000

- Application: cow dung, chicken poop, pig manure, sludge, biogas waste, etc.

Top 4 manure dehydrators for manure organic fertilizer production

Our manure dewatering machines are constantly innovating and pursuing new technologies for animal manure water removing. At present, we have 4 types of dewatering machine are hot sale. Screw dewatering machine, inclined screen solid-liquid separator, rotary drum dewatering equipment and stacked screw dehydrator.

Economical screw type dewatering machine

If you need a economical manure dewatering equipment, the screw type is an idela choice. Only $2,500-$50,000. It mainly relies on the pressing force between screw and screen to separate liquid from solid. With 0.3-0.5 mm screen holes, it can reduce the 50%-70% moisture organic material to 30%-40% quickly and easily.

| Model | Capacity (m³/h) | Power (kw) | Dimension (mm) |

|---|---|---|---|

| SXTS-180 | 10-15 | 4 | 1850x650x1150 |

| SXTS-230 | 15-20 | 5.5 | 1850x800x1150 |

Inclined screen dehydrator for over 80% moisture manure disposal

However, if you want to dry manure with a water content of over 80%, inclined screen solid-liquid separatoris better. Because before pressing, it will separate solid from liquid simply. Then there is a screw pressing design to further remove excessive from organic materials. It is an ideal choice to dry cow dung, pig manure, horse manure, etc.

| Model | Capacity (m³/h) | Power (kw) | Dimension (mm) |

|---|---|---|---|

| SXTSX-800 | 15-20 | 4 | 1700x1500x1300 |

| SXTSX-1200 | 30-40 | 5.5 | 2200x1500x1700 |

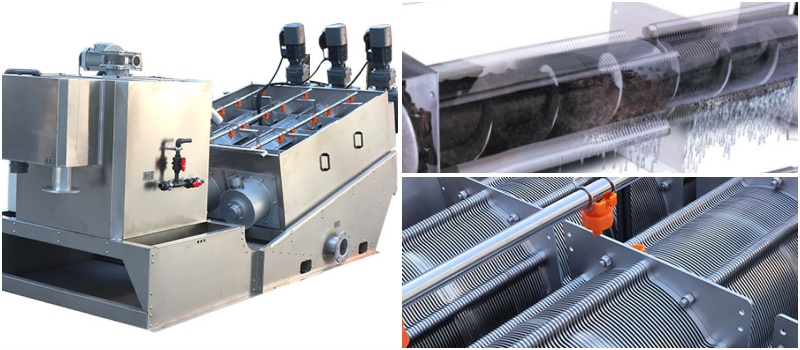

Stacked screw solid-liquid separator with better filtering

In addition, for thoes who need a dewatering machine with better filtering effect of manure or sludge, we especially design stacked screw dehydrator. You can add flocculants to make small solid particles clump together. This is beneficial for not only drying manure better, but also get lqiuid manure material with less impurities, which is suitable for liquid fertilizer making. At the same time, it has advantages of compact design, automatic cleaning design, no blocking, etc.

Large scale Rotary drum manure dehydrator

Is there a dewatering machine for larger scale manure waste disposal? Of course. For this, we also can offer you with rotary drum dehydrator. It combine rotary drum with screw type pressing design. In this way, it can dewater more manure waste in the same time. It is the most suitable one for your large scale organic fertilizer production line.

They all are excellent choices for you to separate animal excrement, distillers’ grains, medicine dregs, starch dregs, sauce dregs and other high concentration organic sewage from chickens, cattle, horses from slaughterhouses or intensive farms.

Contact us now to start your manure dewatering project!

What is the features of YUSHUNXIN manure dehydrator?

The dewatering machine for manure from our company can separate the dry and wet animal excrement quickly. And the separated dried manure is almost odorless. And can used as fish feed, planting, and raw materials for different kinds of fertilizer production.

Dewatering manure quickly

This series of dewatering separator machinee can separate the solid from the liquid quickly. After dewatering by these machine, the water moisture will reduce to 30%. It is an ideal choice for both transportation directly or using as raw materials for organic fertilizer production. What’s more, you can also adjust the slag output and water content to meet different needs.

304 stainless steel adoptation

The body and frame are made of high erosion-ressitance alloy with additional anticorrosive treatment. In particular, we use 304 stainless steel to manufacture parts (like screen, screw, etc) which directly contacts the material with a large area. So, it has good corrosion resistance and enough strength for long service life.

No blocking

Our manure dewatering equipment even have strong ability of decontamination. So, there is no blocking and easy to clean.

High Economy

Our screw press dewatering machine for manure has high degree of automation, low power consumption and low price. And it is easy to operate in any working conditions

Get your own manure dewatering equipment now!

What is the dewatering effect of the YUSHUNXIN solid liquid separator for manure?

The deawtering machine from YUSHUNXIN company is a professional dewatering equipment to deal with different kinds of materials with high moisture content. It adopts the principle of screw press which can control the discharge speed and water content of the materials freely. What’s more, it can finish its work quickly and the waste water will be extruded from mesh screen and flows out of the drain pipe. In general, the moisture is about 30% after dewatering by our solid liquid separator machine. If you have other requirements for water content after dehydration, it is adjustable to meet your needs.

Start your organic waste dewatering immediately!

How does YUSHUNXIN dewatering machine handle fresh chicken manure effectively?

Chicken manure is a kind of familiar excrement in poultry farms. People who raise chickens in large quantities there will produce large amounts of chicken manure in their farms. But don’t worry, our chicken manure dewatering machine can help you handle them effectively. When you use this dewatering machine, the pump of solid liquid separator lift the fresh chicken manure into the dehydrator. Then, the screw press wring dragon gradually pushes the water of chicken excrement to the front of the body, and continuously increases the pressure at the leading edge. Under strong extrusion pressure, redundant water in the chicken manure will be squeezed out of the screen. When the extrusion pressure reaches a certain level, the discharge port will open to release the dried manure and the dewatering process finished. Then you further process chicken manure into organic fertilizer.

What role of solid-liquid separator in manure waste disposal?

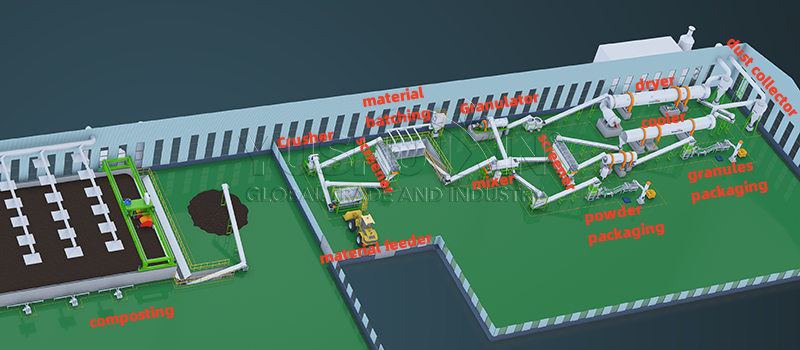

After dewatering, the manure waste is easier to transport. What;s more, both the solid manure waste and lqiud manure slurry can processed into quickly organic fertilizer.

For one thing, you can make solid manure into quality solid organic fertilizer. By regular turning with compost machine, you can get high quality organic compost fertilizer. In addition, with the help of organic fertilizer pellet machine, you can easily make organic fertilizer granules from compost for commercial market sale.

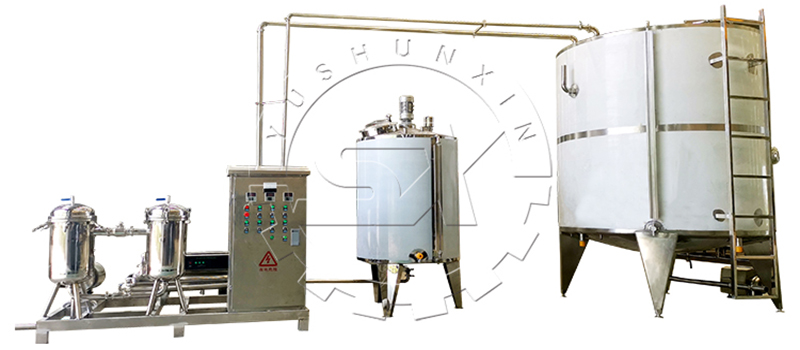

For another, you also can produce liquid organic fertilizer from manure waste. After dewatering, manure slurry material will pass processes of filtering, UV sterilization, nutrient batching, anaerabic fermentation, testing. Finally, you can pack produced liquid organic fertilizer to sell.

In addition, there are also many other machines for organic waste disposal. Such as organic fertilizer granulator, compost machine, rotary dryer, packing equipment, etc. Welcome to know them now!