Dry granulation equipment is a kind of fertilizer granulating machine that uses dry granulation method. During this process, there is only a mechanical process that changes the physical properties of the powder material, and no chemical reaction occurs. Therefore, it requires no subsequent drying process, so achieving low energy consumption; and consumes less auxiliary materials, it is beneficial to improve the stability of particles and facilitate storage and transportation. As a professional fertilizer equipment manufacturer, SX designs two dry granulation machines to meet customers’ needs. They are double roller extrusion granulator and flat die pelletizer. You can produce high quality fertilizer granules with them easily.

Main Paramaters

- Capacity:1-3 T/H

- Granule Size:1-10 mm

- Granulation Rate: 93%-95%

- Pellet shape: Flat ball or column

- Feeding Material Moisture: Lower 10%

- Cost:$3,000-$12,000

- Application: Both organic and compound fertilizer granulation

How to start dry granulation fertilizer production?

What is dry granulation method?

In today’s world, there are two most popular granulating methods in fertilizer manufacturing: dry granulation and wet granulation. Dry granulation is a process whereby granules are formed without the aid of any liquid solution. There is only a mechanical process that changes the physical properties of the powder material, and no chemical reaction occurs. It is also a roller extrusion process, which compresses the powdery materials with a moisture content of less than 10% into flakes or blocks. And crushes and sieves to make the flakes and blocks into granular materials that meet the requirements of use.

Why dry granulation is favoured than wet granulation in fertilizer making line?

As mentioned above, both dry granulation and wet granulation are good granulation methods in fertilizer preparation . According to statistics, in the process of fertilizer production, a large part of fertilizer producers like to use dry granulation method, so why can dry granulation attract them?

Which equipment is used for dry granulation process?

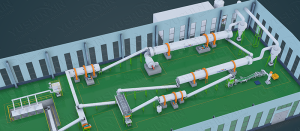

Compared with wet granulation equipment, there are fewer types of dry granulators we can provide you. Only two types: double roller extrusion granulator and flat die pelletizer. Some basic information about them showed for you is as follows:

Double Roller Extrusion Granulator

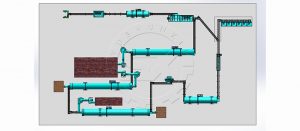

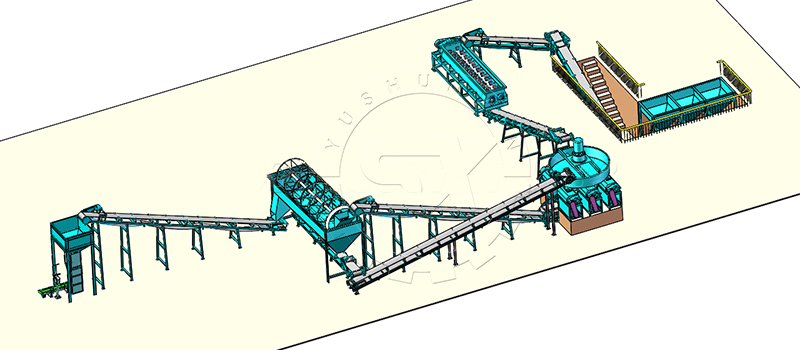

Double roller extrusion granulator is a hot sale granulating machine for NPK fertilizer production. It has a capacity of 1~3 t/h, and can make granules with a diameter of 3~10 mm. Moreover, it can support the corresponding equipment, forming a small production line to achieve a certain capacity continuous, mechanized production. If you have a special requirement for granule size or shape, it also can meet your needs. It can provide ball socket customization, such as pillow shape, semicircle shape, stick shape, pill shape, walnut shape, flat ball shape and square bar shape.

Double Roller Extrusion Granulator

- Capacity: 1-3 t/h

- Final granule size: 3-10mm

- Feeding moisture content: < 10%

- Material: urea, bentonite, mineral powder, zeolite, snow melting agent, graphite, fragrance beads,etc

Flat Die Pelletizer

Flat die pelletizer plays an important role in various organic substances granulation after fermentation. Its capacity is about 1~2.5 t/h, it is suitable for starting a small scale organic fertilizer production. Moreover, it can combine with a variety of molds. So you can produce columnar particles with different diameters to meet customers’ different needs. The granules processed by this machine not only have smooth surface, moderate hardness, but also can maintain internal nutrients during processing. It is really an economical dry granulation equipment for you.

Flat Die Pelletizer

Capacity: 1-2.5 t/h

Final granule size: 2-10mm

Feeding moisture content: < 10%

Material: cow dung, chicken poop, pig farm waste, goat manure, horse manure, mushroom waste, sugar waste, etc

How does the dry granulator work in your fertilizer production?

Although both double roller extrusion granulator and flat die pelletizer adopt dry roller compaction technology, there are some differences between them.

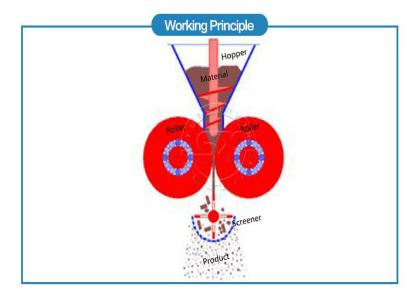

Double roller granulator

There are two rollers with many small ball sockets inside our double roller granulator, and they are on the same level. When you feed the fertilizer powder into the machine, the two rollers will rotate in opposite directions. Then the powder material will be squeezed into particles through the gap between the two rollers. In addition, you need to keep the minimum distance between the two rollers at 0.3-1 mm.

Flat die pelletizer

Unlike double roller granulator, flat die pelletizer is based on circular motion and extrudes by using rotating extrusion rollers and molds. After the machines set in motion, the fertilizer powder will be pressed in mold holes by rotating rollers, and turned into long cylindrical pellets. Finally, inner shearing knives will cut them into granules with proper length.

When you choose to use dry pelleting equipment?

From the above statement, you must have a certain understanding of dry granulation equipment. So under what circumstances is it better to use dry granulating equipment?

If you are granulating with moisture sensitive materials, the dry granulation equipment is a better option. Because the whole process goes almost without water, the moisture sensitive materials will preserve their functionality after the granulation. You can easily achieve it with dry granulation method, but it will be hard to do this by other means.

If your fertilizer materials are unable to withstand elevated temperature during drying, using dry granulation equipment is a good way to solve this problem. The powder materials are directly granulated without subsequent drying process. You have no need to worry about high temperature reducing fertilizer quality.

If your budget is not high, the dry granulation equipment is also an ideal choice for you. The dry granulator is simple in principle, easy to operate, and its finished granules have low moisture content and no need to dry, so fertilizer manufacturing becomes simpler. It can provide you with a more economical fertilizer production line.

Why choose us from so many dry granulation equipment manufacturers?

In addition to determining the type of machine you need, it is also important to choose a reliable company. SX Engineering Equipment Co.Ltd. is absolutely an excellent choice for you because we can provide you with the best service.

- Before the sale, upon receipt of customers’ information, we will promptly reply through telephone and email. We will provide customers with one-stop professional services, including product inquiry, technical support, product service complaint, warranty, consultation of spare parts, etc.

- During the sale, we can design a project for you free of charge and guide the installation on site. Ensuring your follow-up production.

- After the sale, we will follow up and visit irregularly. And understanding the machine operation, production capacity, service condition of wearing parts and other problems encountered by the customer at this stage. Then help them solve the problem immediately and give more technical guidance.

As a professional fertilizer equipment manufacturer, our company will provide you with high quality fertilizer making machines at the best price. Whether you want to build a new fertilizer production line or upgrade an old one, whether you want to start a organic fertilizer production or compound fertilizer factory, you can contact us for consultation.