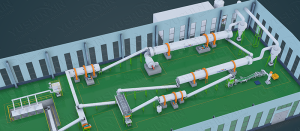

Wet granulating equipment is a type of fertilizer granulator, which is widely used in organic and compound fertilizer production. Because it makes fertilizer granules with liquid as binder. In this way, there is a higher adhesive property of powdery materials. So you can convert the material into granular fertilizer faster. There are four types of granulating machines, which employ wet granulation method. They are pan disc granulator, new type organic fertilizer granulator, rotary drum churning pelletizer and rotary drum pelletizer. If you have special requirements, you can contact us for customization. We can fully meet your needs.

Get your customized fertilizer granules making plan!

What is wet granulation in fertilizer production?

There are two common granulation methods for fertilizer production: dry granulation and wet granulation. Dry granulation is a process whereby granules are formed without the aid of any liquid solution. However, liquid is essential during the wet granulation process. In general, if your materials have a moisture content of 20%-45% after composting, you don’t need to add water. But if the moisture content of the material is not enough during granulation, you can add liquid as a binder. Such as water, organic solvent or glue solution. It can wet the powdery materials and improve adhesive force between the materials. Then the materials will combine, agglomerate and turn into particles in a shorter time. And finished granules will have high hardness and not easy to break. Therefore, wet granulating equipment plays an important role in high quality fertilizer granules preparation.

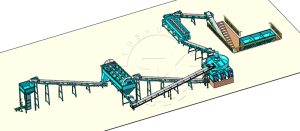

4 Hot sale types of wet granulating machines in SX fertilizer machinery

According to the current investigation into customers’ needs, our engineers design four pellets making machines for wet granulation. At present, they have won good feedback from countless customers. There is some information about them shown as follows:

Pan granulator for 1-6t/h capacity fertilizer production

If you need a wet granulator for a small or medium scale fertilizer production line, pan granulator is an excellent choice. Because it has a capacity of 1-6t/h, which fully meets your needs. And its granulation rate can reach more than 93%. It means that you can produce more pellets with the same amount of material. Besides granulation rate, the quality of the pellets is also an aspect you concern. If the moisture of materials is insufficient during wet granulation, the quality of the granules will decrease. Disc pelletizer has a liquid spraying device above. It is convenient for adding water or other additives. So, using pan granulator, you can produce high quality fertilizer particles easily.

New type organic fertilizer granulator

If you want to make organic fertilizer in a larger scale, we can provide you new type wet fertilizer granulator. It is also known as stirring teeth pellet making machine. It makes use of two forces to make fertilizer pellets. They are mechanical stirring force of high-speed rotation and the resulting aerodynamic force. Under the combined action of them, the conglomeration rate can reach 97%. You can use it to produce 2-5 mm fertilizer pellets from various organic materials. Such as chicken manure, cow dung, mushroom drugs, biogas fermentation residues, etc.

Rotary drum pelletizer for compound fertilizer production

Is there a wet granulator suitable for compound fertilizer production lines here? Of course. Drum granulator is an advanced equipment in the field of complex fertilizer production. Whether you want to produce NPK fertilizer 20:10:10 or 15:15:15, drum pelletizer can produce it exactly as required. And there are various types of drum granulators. They can meet the different needs of customers for capacity. SXZGZ-3210 has a large capacity of 15-30 t/h, which is higher than other wet granulating machines. It is an ideal choice for starting a large scale compound fertilizer preparation. If you plan to make complex fertilizer in a small or medium scale, we can provide you with SXZGZ-1240 and SXZGZ-1870. Their capacities are 1-3 t/h and 5-8 t/h respectively.

Two-in-one rotary drum churning pelletizer

If you want to buy a wet granulating machine, which is not only suitable for organic fertilizer production, but also proper for compound fertilizer making. Besides pan granulator, rotary drum churning pelletizer is also an excellent choice for you. During the fertilizer process, the rotating drum and inside stirring teeth will work synchronously. So compared with the rotary drum granulator, it has a higher granulating rate of more than 90%. And the granules produced by this wet machine are more uniform. So, you will return fewer pellets to re-granulate.

These four wet granulating equipment are our hot sale products. They can help you make high quality granular fertilizer. Whether you plan to build an organic or compound fertilizer plant. Whether you want to start a small, medium or large fertilizer production. If you need more details you can contact us. We will reply to you by phone or email as soon as possible.

Tips for selecting a suitable wet granulator from above four granulating machines

These four wet granulating machines are popular with fertilizer suppliers. Do you know how to select the most suitable one from them? There are four items you need to consider:

Fertilizer production scale

This is a critical factor for wet granulating equipment selection. If you need a granulating machine for a large scale fertilizer production plant, rotary drum pelletizer is an optimal choice. There are two models of rotary drum pelletizer for you: SXZGZ-3210 and SXZGZ-2080. The former has a capacity of 5-30 t/h, is higher than other granulating equipment. The capacity of the latter is 8-15 t/h, it is slightly lower than the former. They are all suitable for mass fertilizer production. And if you want to build a small fertilizer manufacturing line, pan granulator is the most recommended model for you. It can prepare 1-6 tons of granular fertilizer per hour.

Your budget

If you plan to make organic or compound fertilizer, budget is an important item you must consider. Different types of wet granulating machines have different prices. And Prices will vary with their capacity and configuration. If your budget is enough, we suggest you choose rotating drum granulating machine. But if your budget is not enough, disc granulator is economical for you. We will design the most efficient plan according to your budget.

Factory area

Your factory space must be able to fit the entire production line. So, you must choose equipment according to your workshop space. If your fertilizer plant has a large space, rotary drum granulator or rotary drum churning pelletizer is an ideal choice for you. If your workshop area is not large, it is advisable to choose disc pelletizer or new type organic fertilizer granulator.

Your materials

If you want to dispose of organic waste, it is advisable to choose pan granulator and new type organic fertilizer granulator. If you plan to start a compound fertilizer manufacturing project, rotary drum pelletizer and rotary drum churning pelletizer are better than others.

Learn more about your ideal fertilizer granulation equipment!

Why we need wet granulation equipment in organic and compound fertilizer production?

Compared with dry granulation equipment, wet granulating machine has many advantages to attracting fertilizer suppliers. For example:

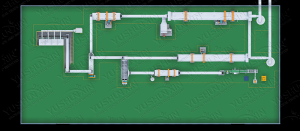

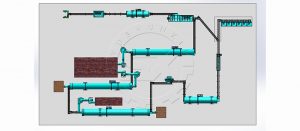

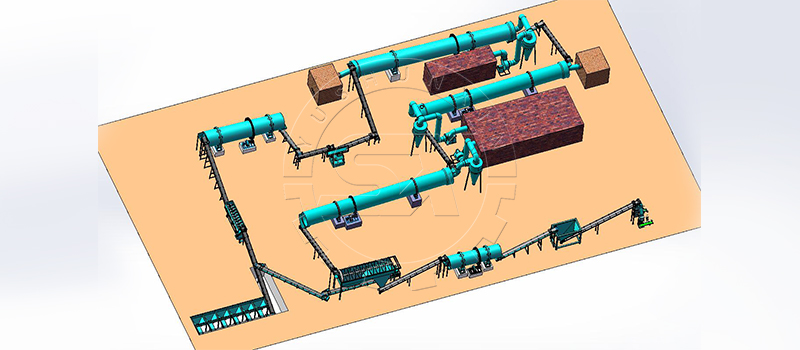

Process of wet granulation in fertilizer production line

In summary, wet granulation process involves 5 main stages: preparing material, wetting powder, granulation, drying and cooling. There are more details as follows:

Before granulating

You have to complete two tasks: preparing materials and wetting powder.

- Preparing materials: Before granulating, you need to compost, pulverize and mix organic materials; and inorganic materials only need to be ground and mixed into powder.

- Wetting powder: Wetting means adding the right amount of water or binders to help powder materials to clump.

While granulating

When the raw material is wet, there is an adhesive force generated. The materials will absorb and stick to each other. Then under the action of centrifugal force or compaction between particles, the materials will gradually become the particles we need.

After granulating

Turning materials into pellets is not the end. It still needs further processing to improve pellets quality: drying and cooling.

- drying process: After granulation, the water content of the granulated product is still high. Especially organic fertilizer granules, between 15%~20%. But the standard fertilizer moisture content is 14%. So the drying process is necessary for you. You need to choose the right drying equipment to get the job done quickly.

- Cooling process: The high temperature will make the moisture inside the pellets move to the surface. The pellets will become easier to clump. So you need a cooler to lower the temperature.

Why SX can provide you with economical fertilizer wet granulator

“Economical” means that high quality and low price, these are what we desire when we purchase anything. Of course, including wet granulating machine. SX Engineering Equipment Co.Ltd. can supply you with the most economical equipment used in wet granulation. Why?

- SX has mature production technology. It reduces the cost of fertilizer equipment manufacture. So we can offer you an excellent price. SX was established in 2005, and has nearly 20 years of experience in the production of organic fertilizer and compound fertilizer equipment. So it has mature technology on wet granulator manufacture and can provide you with a lower price.

- SX wet pelleting machine has a long service life, so your fertilizer production cost becomes lower. The wet granulating equipment is made of high temperature resistant and anti-corrosion materials, which meets international standards. Therefore, you can use it for a long time and don’t need replace it frequently.

- SX will provide you with the best service free of charge. We can provide you with free process design drawing, configuration plan, forward guidance according to your requirements.