For most of fertilizer manufacturers, the choice of the fertilizer production equipment is crucial to the development of the composting business. Some people will choose low volume composting equipment, while others will choose high volume composting facility for organic wastes composting. In fact, apart from the difference in production capacity, there is no difference between them. But, compared with the small scale composting, large volume composting brings higher economic benefits and the whole composting process is more commercial. So, many fertilizer business operators are willing to invest in large scale composting equipment for their plants.

Main Parameters

- [Capacity] 10-20 T/H

- [Application] Dispose of animal manure, biogas waste, sugar factory waste, straw, rice hull, etc.

- [Composting Time] 10-20 days

- [Feeding moisture] 50%-60%

- [Moisuture After Compost] 30%

Which is the best equipment for your large scale composting?

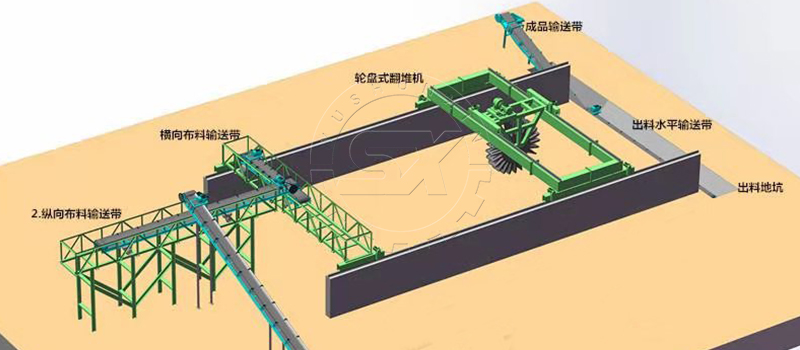

If you asked which kind of compost turning facility can help you do large scale compost turning, we will recommend you with the large wheel type compost turner. This type compost turner is the patent product of our company. It is especially designed for large scale raw materials composting process. Besides, it has the fully automated electrical control system and can work without workers. Compared with the traditional fertilizer compost facilities, it has higher turning depth and larger turning span. Generally speaking, the largest turning span of this machine can be 30 meters. According to your demand for output, this kind of compost turners can be customized for you. So, if you want to compost in a large scale, this type compost turning machine will be a good choice for you.

Large scale wheel type composting equipment

- Turning Depth: 1.5-3m

- Turning Span: 2.5-30m

- Product Category: Composting Equipment

- Features: Automatic Compost Machine

- Service: Customized

Are there other large scale industrial composting techniques designed for organic fertilizer making?

For large scale industrial composting operation, you also can carry out it in the form of in-vessel composting and windrow composting.

Large scale windrow composting

The windrow compost turner machine from SEEC is another composting equipment for large scale fertilizer composting work. It raises the turning of organic waste to a new level. With the help of SEEC windrow compost turners, you can compost your organic waste in a more efficient way, about 500-1500 m³ per hour. So, it is the ideal compost turning machine for operators who want to turn large volumes of organic material quickly on the ground directly. In SEEC, there are different type professional windrow composting equipment for you. Crawler type compost turner and moving type windrower. If you are interested in them, just feel free to contact us.

Large scale in-vessel composting

SEEC in-vessel composter for sale is a large scale composting equipment. It takes the advantage of decomposition of microorganisms in nature. During the fermentation process, the high temperature promotes the decompose the organic materials. At the same time, it will kill parasites, germs and other harmful substances to achieve harmless treatment. What’s more, it adopts aerobic fermentation technology to let the organic material fermenting continuously in a closed vessel. So, it can be used for the fermentation of different kinds of animal manure, municipal solid waste, sludge waste and other organic wastes in our life.

How does 100,000 tons large scale compost fertilizer production line running smoothly in fertilizer plant?

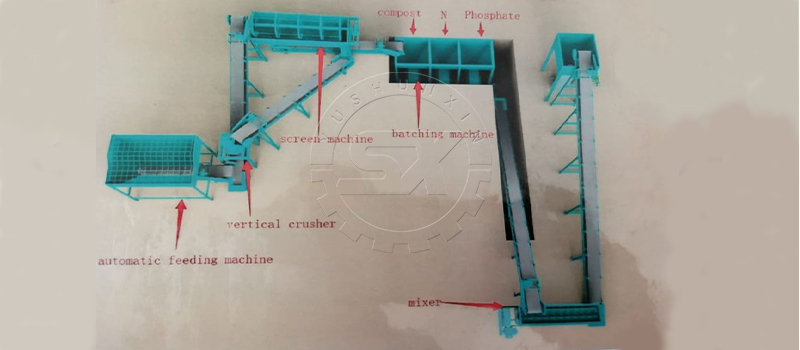

100,000 tons/year compost fertilizer production line is a large scale composting project. Because you need to prepare 15-20 toms of manure compost an hour, wheel type compost turner will be the best choice. Besides, there are many other machines can help you compost organic materials faster and make compost into commercial organic fertilizer. Such as fertilizer crusher, fertilizer mixer, compost screener and automatic packing machine.

- Crushing organic materials into finer powder – the smaller particle size material can enlarge the contact area with oxygen. It is greatly beneficial for aerobic fermentation.

- Mixing manure compost with other materials evenly can help you prepare organic fertilizer not only with richer nutrients, but also with uniform nutrient distribution.

- Sieving finished fertilizer compost is to improve the purity of final organic fertilizer. Because rotary screener will separate required fine powder from waste like cigarette butts, small stones.

- Packaging machine is necessary for commercial compost fertilizer making. Packaged compost fertilizer is more convenient for transport, storage and use.

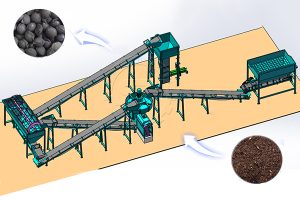

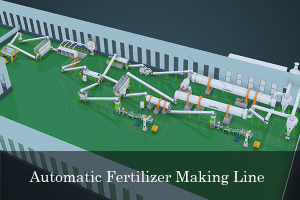

From raw material processing to the final product packaging, the whole production line can run smoothly. Besides, after the completion of the current process, the organic materials will be transported by the belt conveyor to the next production process. Meanwhile, we also design large scale fertilizer granulation production line for you. If you have any questions about the design of our production line, welcome to contact us freely.

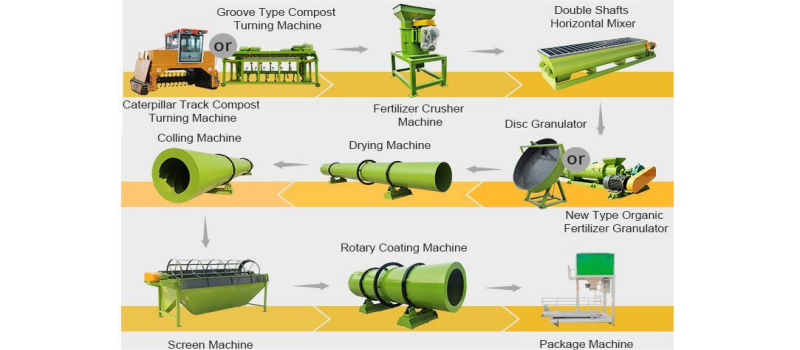

What is the process to make organic fertilizer granule on a large scale?

The organic fertilizer granulation system is is based on the above composting line. In organic fertilizer pellets making process, after composting, crushing, mixing, screening, you need to turn powder compost fertilizer into granules. Then you also need to further improve fertilizer pellets quality by drying, cooling, coating.

- Granulation process: For organic fertilizer pellets making, it is no doubt that granulator choosing is essential. Then, for large scale organic fertilizer granulation, we recommend you buy rotary drum granulator. Its largest capacity can reach 30 t/h. And it has characteristics of low energy consumption, sticking prevention design, easy operation, etc.

- Drying and cooling: During this process, the fertilizer granules will be processed by dryer and cooler for excessive moisture removing. The waster content of final organic fertilizer pellet is lower than 10%. Therefore, it is easier to transport, store and use.

- Coating: Coating machine can fully meet your requirements for colored, rich-nutrients and slow release organic fertilizer production.

- Packing the products: Packaging is the final step in fertilizer production. For large volume composting system, a fully automatic packaging equipment is also essential to you.

Other auxiliary facilities you may need for large scale composting operations

A complete production line is always inseparable from auxiliary equipment. They are not vital but they are useful to the production process. For example, the belt conveyor helps connect the whole production line well and you do not need works to transfer the processing materials from one place to another place. Cache storage bin helps slow down the transportation of materials etc. Here are some auxiliary equipment in large scale compost production.

What kind of material can fit large scale composting machine?

As we mentioned above, large scale compost systems have different types in our company. To some extent, the large scale composting method or technology, large scale anaerobic composting, adopts aerobic compost to prompt materials fermentation. Therefore, large scale compost machine is very popular around. In addition, in terms of the origin materials, they have similar features. For example, all kinds of manure, agriculture waste, sludge, etc.

Animals and poultry manure

As we known, all kinds of manure have many functions for modern fertilizer industry. They contains a lot of nutrition to prompt the growth of various of plants and improve soil structure in case of increase soil solidification. Therefore, manure often be used as a kind of based fertilizer for making fertilizer. What is more, it has high economic value in fertilizer industry.

Agricultural waste

Those waste are mainly straw sawdust, died plants, etc. Furthermore, more than half of the photosynthetic products of crops are found in straw. It contains rich nitrogen, phosphorus, potassium, calcium, magnesium and organic matter, etc., and renewable biological resource with multiple USES. Therefore, it plays an important role in fertilizer materials.

Why does SEEC can provide you with the high quality compost facilities for large scale composting?

SEEC, is the professional fertilizer production equipment supplier in China. For composting equipment, we have our own manufacturing factory and r&d team to provide technical support. So, if you want to buy a large scale composting equipment for your large scale composting operations, welcome to visit our factory and contact us at any time. With nearly more than 30 years of equipment production experience, we are surely to provide you with the high quality large scale composting facilities and professional service.