With the development of edible fungi industry, the scale of fungi planting increases greatly. Especially the growing of commercial mushrooms. But it will generate a large amount of waste, including corn cobs, sawdust, cottonseed husks, etc. But in fact, commercially available ‘spent’ mushroom substrate is not always truly spent. Although they can not provide enough nutrients to grow mushrooms well, they can become good raw materials to make compost fertilizer. In this process, YUSHUNXIN can provide you with suitable mushroom compost machines to help you finish mushroom litter fermentation quickly and easily. In addition, you can choose to further make mushroom compost into powdery or granular organic fertilizer.

Main Parameters

- Capacity: 1-20 t/h

- Compost time: 15-20 days

- Equipment types: Groove/Windrow/ in-vessel

- Equipment material: Carbon steel Q235 or stainless steel

- Application: compost making, mushroom waste disposal

Tips: Additional materials like gypsum, peat moss, lime, soybean meal, and various other organic items may be added to the compost as well.

What is the key step in mushroom compost making process?

During the mushroom compost making process, the most important process is the fermentation of organic waste. But how to make mushroom compost quickly? It is necessary to use professional mushrooms compost machinery.

With the help of mushroom compost turning machine from YUSHUNXIN, you can turn mushroom substrate deeply and regularly in a large scale. This is beneficial for improving the acitivity of microorganisms and generate more heat. As the temperature of mushroom waste compost pile increases, the harmful substances in organic material will be killed. Incluing pathogens, pest eggs, grass seeds, etc. So a professional mushroom compost machine can help you speed up the fermentation of mushroom waste and make commercial organic fertilizer.

What kinds of equipment can help you make high quality mushroom waste compost easily?

In YUSHUNXIN company, we have various types of mushroom compost making machines to help you make mushroom waste into high quality compost fertilizer. They adopt the most advanced aerobic fermentation technology to decompose the mushroom growing materials fast. Here are some hot sale mushroom compost machines recommended to you:

Top 1: In-vessel fermentation tank for fast mushroom waste composting

Do you want to complete the composting of mushroom waste faster? You can choose our in-vessel fertilizer fermentation tank. It is a patent product of our company. The unique closed composting environment design ensures the efficiency of mushroom litter aerobic fermentation. Because it greatly reduces the influences from the outside world, such as seasons, extreme weather, etc. In addition, in-vessel mushroom waste composting also has a characteristic of less occupation. There is professional gas waste treatment system for you. Therefore, this type of compost turner is popular for commercial mushroom growers who want to make mushroom compost by themselves.

Top 2: Groove type turner machine for economical compost making of mushroom substrate

Then, if you need a economical mushroom waste composting machine, We recommend you buy our groove type compost equipment. With 2.5 – 5 m turning span and 0.8-1.5 turning depth, it can help you finish the small and even large scale composting of mushroom waste easily. However, the price of the compost turner is only $6,500- 19,000. How does the groove type compost turner work? Just as the picture showing, all the raw materials for mushroom compost making are stacked into the fermentation grooves. Then, under the control of PLC system, the compost machine will turn compost piles regularly and automatically.

Top 3: Crawler windrow compost equipment for mobile compost making

Is there economical mushroom substrate compost turner without fermentation tank? Of course. There is crawler hydraulic compost turner for you. It adopt windrow composting technology, which can start the mushroom waste disposal on the flat cement ground directly. It only needs $10,000 – $30,000. What’s more, its turning width can reach 2.4-3 m and the turning height of this machine is about 0.6-1.5 m. That is, using it, you can process 500-1500 m³ mushroom waste windrows every hour. Moreover, it has versions of hydraulic, driveless, etc. It can be customized according to your requirements for compost making.

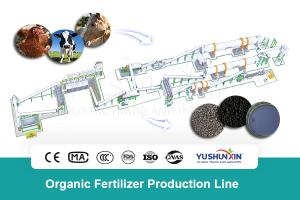

How to process spent mushroom substrate compost into organic fertilizer?

Then after making mushroom waste into compost, there are also two choices for you to further process mushroom waste and make more profits. Making compost into powdery or granule organic fertilizer.

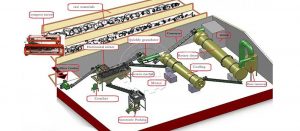

5 steps to make mushroom waste powdery compost fertilizer?

For making powdery organic fertilizer from mushroom waste compost, it only need 5 steps. Feeding, crushing, mixing, screening and packaging. Because simple process, you can produce organic fertilizer from spent mushroom compost quickly.

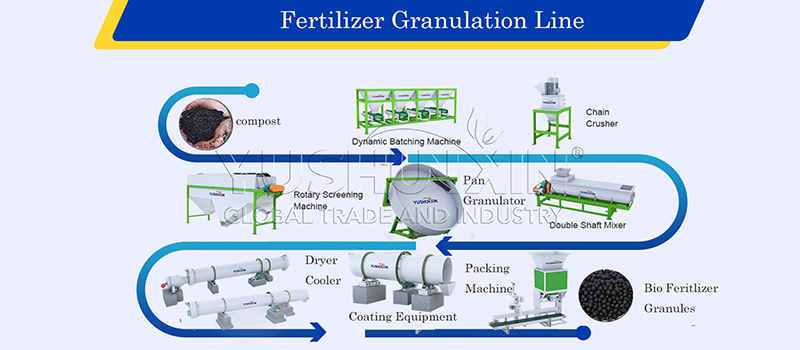

How to produce granular mushroom substrate compost fertilizer?

When you plan to make mushroom waste compost into organic fertilizer pellets, we can offer you batching machine, crusher, mixer, organic fertilizer granulator, screener, dryer, cooler, coating equipment and packing machine, etc. Here, we can design customized organic fertilizer granulation line for mushroom waste compost disposal according to your actual conditions. Such as capacity, budget, area, etc.

Is there operational spent mushroom substrate compost making plant?

The answer is yes. For example, there is a feedback for Moroccan mushroom waste composting and powder organic fertilizer making line. The customer told us ” This mushroom substrate fertilizer production line has been running for 3 months. In this process, it has produced about 10,000 tons of powdered carbon-based fertilizer. It still operate good now. Thank you for your help in design and installation.”

Project Overview

- Location: Morocco

- Capacity: 5 T/H

- Material: Mushroom waste, chicken manure, straw, biochar, etc

- Final fertilizer: powder biochar fertilizer

- Solution: in-vessel compostor, loader type feeder, vertical, crusher, rotary screener, single bucket packing machine and belt comveyor.

- Cost: $45,360

Besides spent mushroom waste, you can make nutritious compost fertilizer from many other materials. Such as cow dung compost making, chicken poop decomposition, etc. Welcome to contact us for the best composting machine for you.