Egypt is one of the top export countries of phosphate fertilizer in the world. In addition, as compound fertilizer, which can supply nutrients to crops in a targeted way, it is beneficial for the development of Egyptian farming. So phosphate fertilizer production is popular with local fertilizer manufacturers. On 11th April 2023, a customer from Egypt inquired about making super phosphate into SSP granule. According to his actual conditions and requirements, we provide him with suitable SSP fertilizer making equipment. The following are the specific details of this case:

Main Parameters

- Country: Egypt

- Capacity: 100 Tons/Day

- Material: phosphate rocks

- Requirements: SSP Granule production

- Solution: Pan granulation line (stainless steel)

- Cost: $225,000

What other materials are needed in SSP fertilizer granule production?

The customer from Egypt emailed us that they had super phosphate as material for SSP granule making. Is there other materials used in SSP fertilizer production?

Of course. In this process, acid liquid is also necessary. Generally, you can choose concentrated sulfuric acid and concentrated nitric acid. What is the difference between them? Using super phosphate + concentrated nitric acid as materials, you can prepare higher quality SSP fertilizer granules.

What is the design of the super phosphate SSP granule making process?

After determining the materials, you can start making super phosphate into SSP granule. In general, you need to take the following steps:

Crushing phosphate rocks in fine powder

This Egyptian client’s solid materials are phosphate rocks, for better SSP fertilizer pellet making, you must turn them into powder. For this, you can use jaw crusher to break rocks into small particles first and adopt Raymond mill to further grind small SSP particles into fine powder.

How to feed raw materials strictly according to the required ratio?

Generally, you can equip acid vessel with a liquid scale to precisely control feeding volume. Then you take the same step in super phosphate powder transport. Or you can transport super phosphate powder by screw conveyor directly and adjust feeding speed of acid.

Mixing super phosphate powder with liquid

Then, mixing super phosphate powder with concentrated sulfuric acid or nitric acid evenly. This is greatly beneficial for ensuring the nutrient balance of final SSP fertilizer you prepare. In this process, we can offer you professional fertilizer mixer to finish the blending of raw materials perfectly.

Acidification and aging

In SSP fertilizer making plant, it is indispensable to set up areas for acidification and aging. Because, you need to put mixture into a closed environment for acidification after mixing. After 3-4 hours, you can get needed materials with a moisture content of 50%-60%. Because of the high water content, you need to age materials to remove excessive moisture.

Processing mixture with SX granulation line

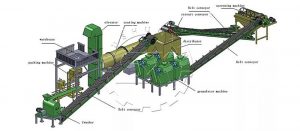

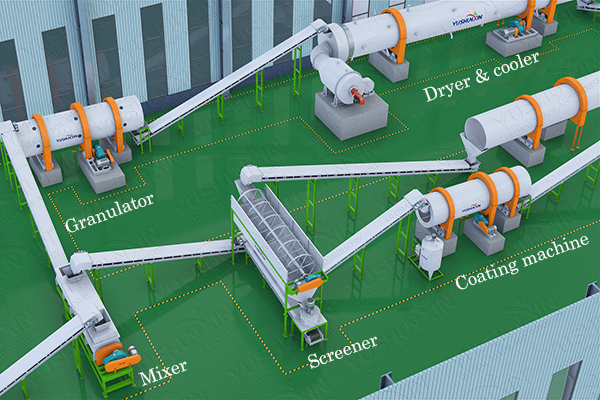

Then it is time to make super phosphate into SSP granule. Here, we design professional SSP fertilizer granulation line for you. It contains chemical shredder, powder screener, compound granulator, granule creener, dryer, cooler and packaging equipment. These chemical fertilizer machines can help you produce high quality SSP fertilizer pellets for you.

Disposing of gas waste

Finally, while making super phosphate into SSP granule, it is essential to focus on fertilizer making pollution control and environmental protection. That is, you need to make exhaust gas of your SSP fertilizer manufacturing meet the international discharging requirements. We recommend you buy our water curtain dust collector. Under the action of water, the gas waste will become hydrofluoric acid and hexafluorosilicic acid.

How to improve the corrosion-resistance of your SSP fertilizer manufacturing equipment?

Because super phosphate + concentrated sulfuric acid / nitric acid will cause servious erosion to equipment. The client from Egypt asked us can the SSP fertilizer making equipment withstand the corrosion? Of course, all our fertilizer machines are made with high strength steel. In addition, there are two methods that can further improve corrosion-resistance.

Adding stainless steel lining

Stainless steel has high performance in erosion-resistance. Therefore, using it as materials to manufacture NPK compound granulator with a longer service life. If you need, YUSHUNXIN can provide you with stainless steel disc granulator for your SSP fertilizer making plant.

Purchasing rotary drum granulator

In addition, you can choose to buy a drum pelletizer for your project of making super phosphate into SSP granule. It is equipped with rubber lining and stainless pressing strips. So, this machine can greatly reduce the corrosion of chemical materials processing.

The above are details about our communication with the customer about making super phosphate into SSP granule in Egypt. In addition, we can also provide you with many other compound fertilizer making business plans. Such as NPK fertilizer production plan, bulk blending fertilizer manufacturing line, etc.