The Philippines is a country that makes animal husbandry a priority industry. It provides strong policy support for farmers. Including policy support on production, market, training and related systems. Therefore, there are many poultry farms in the Philippines. For these poultry farm owners, poultry waste management is important. And making it in organic fertilizer is an ideal choice for them. So on 18th July 2022, a customer from Philippines who has a 240,000 birds farm inquired us about it. The following are the specific details of the case of chicken manure fertilizer production line for 240,000 birds farm in philippines:

Project Overview

- Country: Philippines

- Capacity: 2 t/h

- Material: 240,000 birds farm waste disposal

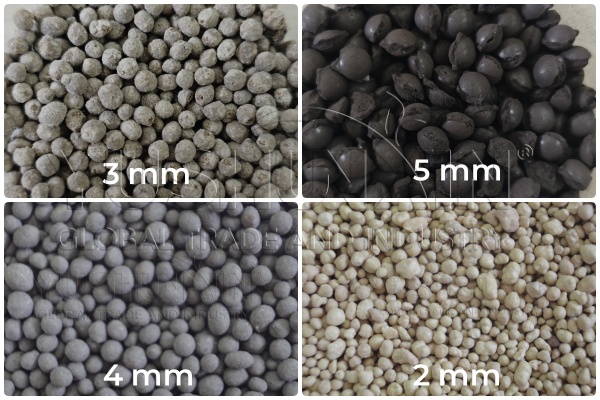

- Requirement : 3-5 mm fertilizer granules Making

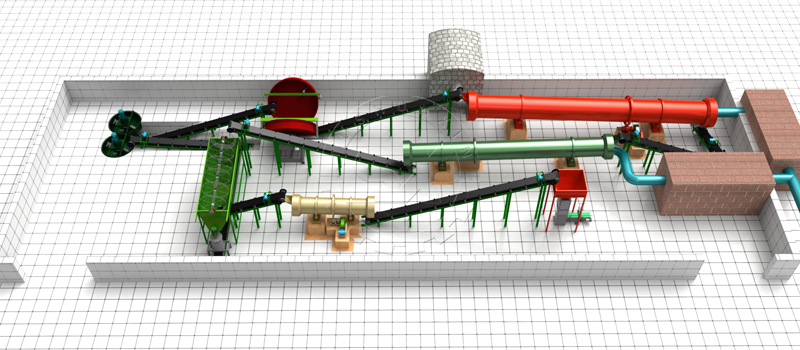

- Solution: Pan granulation line

- Cost: about $150,000

What capacity of organic production line is best for 240,000 birds farm?

This customer from Philippines has a chicken farm of 240,000 birds, so we recommend him choose a 2t/h fertilizer production line for chicken manure.

Because an adult chicken can produce about 0.15 kg of manure a day. So 240,000 birds will produce about 36,000 kg of manure per day, equal to 36 tons. But the chicken manure from the Philippine customer is fresh. It contains solid and water. Only 1/3 of it can be used to prepare organic fertilizer. Therefore, the feces generated by 240,000 birds a day can make 12 tons of organic fertilizer. And considering that you need to add other materials during chicken manure fertilizer preparation. We recommended him a 2 t/h organic fertilizer making line of chicken manure.

Get the chicken manure fertilizer making line now!

What equipment is needed to 2 t/h chicken manure fertilizer granule production line?

From the communication with the Philippines customer, he perfer to making organic fertilizer pellets from chicken manure. Generally, a whole chicken manure fertilizer production line of granules usually consists of 9 parts. Composting, batching, crushing, mixing, granulating, screening, drying and cooling, coating and packaging. Every process has its own unique role. The because of 2 t/h chicken poop granulation output, you needs equipment as follows:

You can choose them according to your needs. And we will design the project according your requirements

Is there a equipment for faster composting chicken manure from 240,000 Birds Farm?

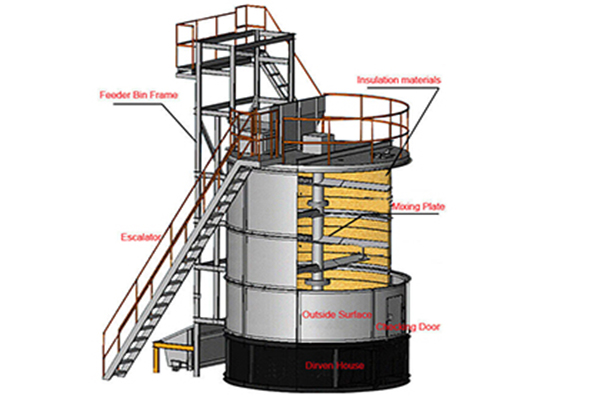

Groove type compost turner is the best economical choice for 240,000 Birds chicken farm manure fertilizer fermenetation. But The Philippine customer was interested in a fast composting one. For this, you can buy a vertical fertilizer fermentation tank.

Because of in-vessel fermentation method employment, it can slow down the heat dissipation and isolate cold from outside world. Therefore, it can help you compost chicken manure faster even in cold winter. It is within 15 days. In addition, vertical fertilizer fermentation tank is your optimal option if you don’t have enough space for chicken manure compost. Only needs 10-30㎡, it can finish material fermentation. And it also can meet your requirement for no secondary pollution. Because vertical fertilizer fermentation tank makes aerobic fermentation in a closed environment. And it has a specialized treatment system for waste gas.

Finally, after negotiation, this customer from Philippines choose the in-vessel fermentation tank for his chicken manure fertilizer production line.

Inquiry the organic manure fermentation tank!

Can 70% chicken manure used in fertilizer granulation? If not, how to dry chicken manure?

As mentioned above, the material from the Philippine customer is fresh chicken droppings. In general, it is a mixture of solids and water. This means it has a high moisture content, which has a serious impact on composting and final produced organic fertilizer quality. Therefore, fresh chicken dropping is not suitable for starting organic fertilizer preparation directly. Then how to adjust the water content of chicken poop and make it suitable for organic fertilizer manufacturing? For this, we can provide you with two solutions for your reference.

Add dry organic materials

If the moisture content of chicken dung is lower than 80% and you want to finish water content reduction at a low cost. You can choose to adjust the waster content of manure by adding some materials with low moisture. Such as straw, corn cob, peanut cake, rice husk, etc. You can mix them with chicken manure or pave them on the bottom layer of fermentation groove to absorb excess water. Then the moisture will decrease to 50%-60%, which is suitable for composting.

Use SX dewatering machines

In addition, if you want to remove excessive water from chicken poop quickly and easier, you can use fertilizer dewatering machine directly. It can separate solid chicken manure and water quickly. And after dewatering, the moisture of chicken droppings is about 30%. Moreover, in order to meet the different requirements of customers, we especially design two kinds of manure water remove machines for your choice. They are inclined screen solid-liquid separator and screw dewatering equipment. The former is more suitable for processing materials with low solid content and high water content of over 80%. Such as fresh cow dung, pig manure, horse droppings, wine waste, etc. But for chicken manure processing, which has low moisture content. We recommend you choose screw dewatering equipment.

The above are details about our communication with the Philippines customer about chicken manure fertilizer production line for 240,000 birds farm . Expect chicken manure disposal line, SX fertilizer machinery also can provide you with many other fertilizer making lines. Such as chicken manure compost system, chicken dung pellet making, cow dung fertilizer processing line, etc.