If you want to make organic fertilizer quickly and easily, it is essential to using suitable organic fertilizer production equipment. As a professional fertilizer machine manufacturer, YUSHUNXIN can provide you with all equipment of the whole set of organic fertilizer processing. Such as drying machine, compost equipment, granulator, crusher, mixer, screener, coating machine, packaging scale, etc. They will will help you pepare organic fertilizer into powder, granules ,etc smoothly and successfully.

Main Parameters

- Capacity: 1-20 t/h

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Pricing: $3,000-$100,000

- Function: composting, granulation, drying, crushing, screening, packaging, etc.

- Application materials: chicken manure, cow dung, pig waste, mushroom waste, biogas residue, , ureaetc

What is the price of your organic fertilizer equipment?

What equipment can be used for organic fertilizer compost making?

Organic composting is a key process in the organic fertilizer making process. Because, during aerobic fermentation process, microorganism activity will generate heat to create a high temperature environment, which can kill the pathogens, pest eggs, grass seeds in organic waste. So, you can use organic waste as fertilizer without harms. In general, under the natural conditions, it needs 3-6 months at least. Is there organic fertilizer composting machines to speed up the process within 20 days?

Of course. Here, YUSHUNXIN design various typical compost turners for your organic fertilizer production fermentation. Including

- wheel type compost turner for large scale organic fertilizer composting

- windrow compost turner for small-medium scale mobile manure compost production

- organic fertilizer fermentation tank for fast organic waste fermentation

- …

How to choose pellets making machine for your organic fertilizer manufacturing?

In addition, granulation is another key process of organic fertilizer production. In this process, organic compost will be made into fertilizer granules, which has a higher value. If you want to turn compost into organic fertilizer granules, there are also multiple organic fertilizer pelletizers to meet your requirements. For example,

- Disc granulation machine for organic fertilizer granulation with higher conversion and economical cost. – over 93% granulation rate and $3,500-$12,000.

- Rotary drum pellet machine for large scale granular organic fertilizer making effectively. – 1-30 t/h per sets and there is rubber lining to prevent material erosion and prolong service life.

- New type organic fertilizer machine can prepare granules with high hardness at a 95% granulating rate.

- Finally, there also are special dry granulation equipment, which can greatly reduce the organic fertilizer pellet making cost. When your material for organic fertilizer granulating has a low moisture of lower than 20%.

After make organic compost into granular organic fertilizer, there are many advantages. Including no sticking and longer time storage, nutrients layering prevention and balance nutrient distribution, slow release and not easy to be blown away by the wind.

Pan Granulator for Organic Fertilizer Making

- Capacity: 0.5-6 t/h

- Powder: 3-18.5 kw

- Disc diamater: 1.2-3.6 m

- Granulation rate: over 93%

- Final granule size: 1-8 mm

- Material: Carbon steel Q235/Alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: Fertilizer granule making from chicken manure/cow dung/pig waste, etc

Which fertilizer granulation machine is more suitable for you?

Top 2 organic fertilizer production equipment for drying organic waste and fertilizer

If you only want to dry organic waste simply, there are 2 types of organic fertilizer production equipment recommended:

Dewatering machine for drying organic waste 90% to 30%

If you need a organic fertilizer production equipment to reduce moisture of animal manure, biogas waste, etc from 50%-90% to 30%, the dewatering machine is the best choice. With physical pressing, it can dry organic manure and waste quickly and at a low investment. Because, there is no extra energy consumption besides electricity. After dewatering, you can choose to turn organic waste into fuel or compost fertilizer according to your needs.

Fertilizer rotary dryer to reduce fertilizer moisture to <10%

But, for those who plan to get organic fertilizer with a water content of lower than 10%, you also need to buy a hot air rotary dryer. Especially, when you adopt wet granulation method in organic fertilizer pelleting. The equipment will dry organic fertilizer by >300℃ hot air. Therefore, you can dry a large amount fertilizer powder or granules in a short time. Moreover, for rotary organic fertilizer drying system, we also can offer you burner and hot blast furnace for drying hot air generation, cooling equipment for temperature reduction quickly, dust collectors for drying dust elimination.

What other types of machines are needed in organic fertilizer production?

The production of organic fertilizer is using the fresh chicken manure, cow dung or any other organic wastes as raw materials to make high quality organic fertilizer. It usually need to experience various processes. Therefore, when you want to produce organic fertilizer, you may need more equipment as follows:

Batching equipment ensure organic fertilizer making inline with ratio

When you produce organic fertilizer with additives, such as straw, NPK, bentonite, etc, a batching equipment is important. It can ensure feeding compost and additives according to the required proportion strictly. Because it adopts electronic weight system or nuclear scale nearly has no weighting error.

Organic waste crusher

In addition, whether you plan to prepare powder or granular organic fertilizer, the fertilizer crusher is necessary. For the former, it can help you make organic compost into fine powder quickly. For the latter, crushed compost is easier to form into 1-8 mm organic fertilizer pellets. In YUSHUNXIN, there are semi-wet organic material grinder for small scale organic fertilizer making and the new type vertical crusher for the large scale operations. Also, you also can find the straw and wood crushing machine for auxiliary material breaking.

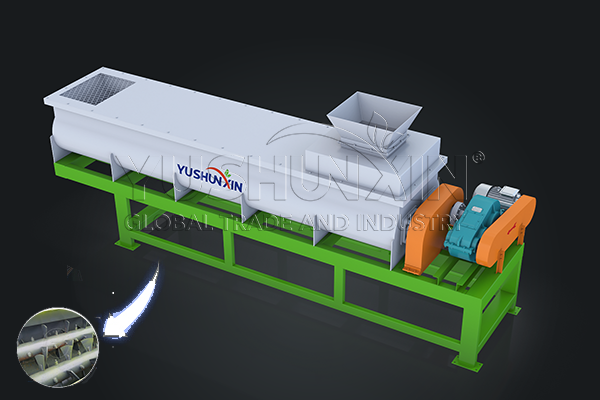

Mixer for blending compost with additives

Then, when you adding other materials like NPK, bentonite, phosphate rock, binder… in the organic fertilizer manufacturing to improve nutrients, the fertilizer mixer is also important. The machine will mix compost with additive materials evenly, which makes nutrient balanced distribution. According to the characteristics of various materials, we design multiple organic fertilizer mixers for you. Such as continuous horizontal mixer, small space disc blender with large capacity, etc.

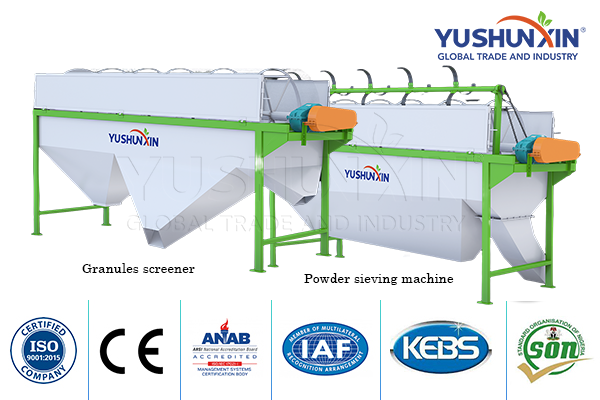

Screener to uniform fertilizer size

To produce quality organic fertilizer, you may also need the screening machine. The powder sieving equipment can remove waste like small stone, cigarette butt, etc from compost. And there also are granules screener, which can sieve out required size organic fertilizer pellets and return the others to crush into fine powder again for re-granulation.

Packaging equipment on the end

Packing is the final process in the organic fertilizer making process. You can freely choose to pack it into 10 kg/bag, 25 kg/bag, 50 kg/bag. It is beneficial for sell your organic fertilizer to different customers. Here, YUSHUNXIN has semi-automatic and fully automatic organic fertilizer packing machines for your choice. Their bagging precision both can reach to 2‰.

How these machine process organic waste into fertilizer?

In general, these machines can fully meet your requirements for processing organic waste into powder and granular fertilizers.

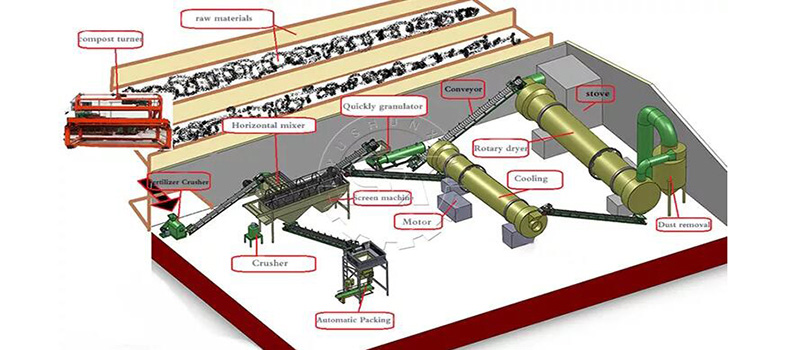

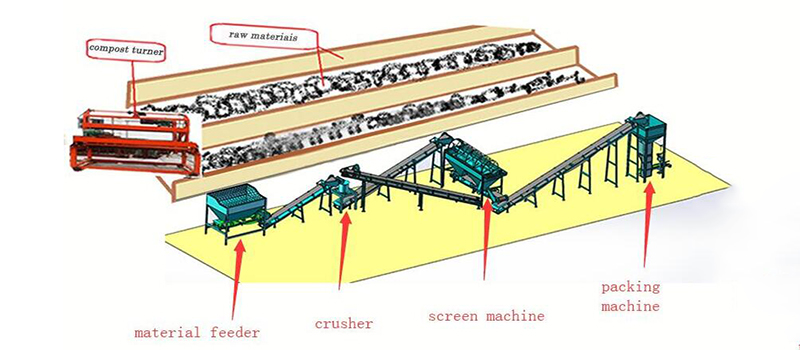

Powdered organic fertilizer making line layout

When you want to make organic fertilizer economically, it is advisable to setup a powdery fertilizer system. For this, you may need 6 organic fertilizer machines. They are fertilizer dehydrator, compostor, batching machine, crusher, screener and packing scale.

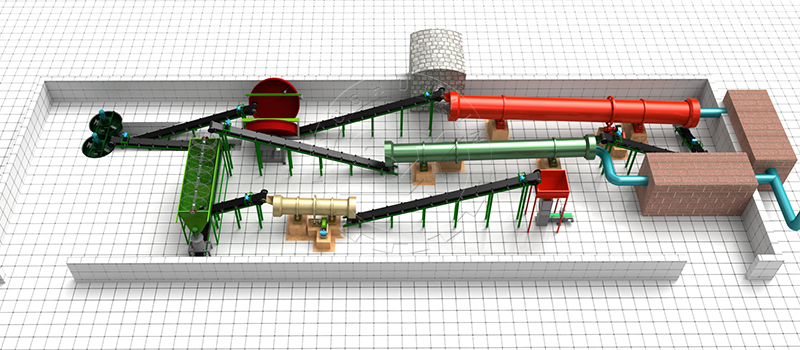

Granular organic fertilizer manufacturing machine

When it comes to granular organic fertilizer preparation, this requires a more complex process which based on the powder fertilizer system. Generally, besides fertilizer dehydrator, compostor, batching machine, crusher, screener packing scale, the system also contains mixer, granulator, dryer, cooler and coating equipment.

Then, according to your material, budget, capacity, etc, the machine mentioned above also can offer you customized organic fertilizer manufacturing plans. Such as cow dung fertilizer making line, chicken manure processing system, bio fertilizer manufacturing solution. Come to get them now!

Inquiry your organic fertilizer making plan now!

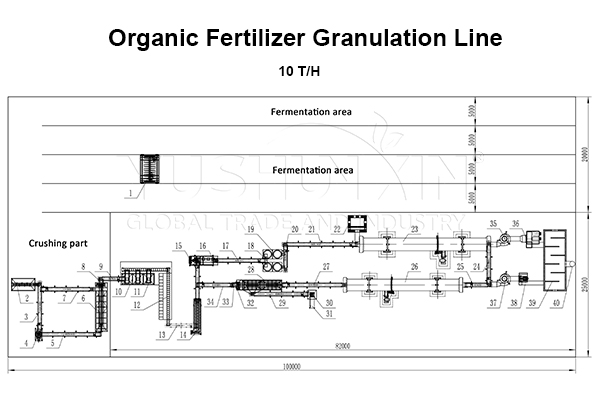

How to set up an organic fertilizer production plant in your country?

Organic fertilizer production is popular in recent years. If you want to set up an organic fertilizer production plant in your country, it is a good choice for you to purchase organic fertilizer production equipment from YUSHUNXIN.

Then, you need to make a detailed organic fertilizer production business plan for your plant. This business plan should be as detailed as possible to make sure your factory runs smoothly. In general, it contains investment, larbor force, area needed, system design, factory layout, etc.

Here, the professional engineer from YUSHUNXIN can help you make a customized plan design and quality machines for your organic fertilizer production project according to your actural conditions. Including the your cost, capcity, area, material, etc of fertilizer preparation project.

Is there YUSHUNXIN organic fertilizer equipment distrinutors overseas?

Of course. In order to talk about your organic fertilizer making plan face to face, we espacially setup 4 overseas branches in Algeria, Indonesia, Russia and the United States, etc.

- Algeria Branch: Rue bouademagh masoude lot numéro 45 – cheraga

- Indonesia Office: Golf Island, JI.Pantai Indah Kapuk Ruko No.20 Blok J, jakarta,Daerah Khusus Ibukota Jakarta 14470

- Russia Branch: 117208, Moscow, Intracity Municipal District Cheratnovo Severnoe, Ulitsa Cheratnovskaya, 7A, Room 6P

- United States Office:12417 E Amherst Circle, Aurora, CO 80014, US

Then, the YUSHUNXIN fertilizer equipment company head office is located in Xingyang City, Zhengzhou City, Henan Province, China. Welcome to visit our factory at any time.

Besides, there are also machines for NPK compound fertilizer making, liquid fertilizer manufacturing, bio fertilizer preparation, etc for your choice. Come to get them immediately!