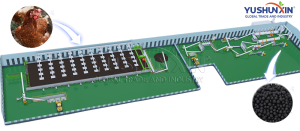

When you want to use animal manure as fertilizer, composting is a necessary process to remove harmful substances from manure. For this, chain plate type compost turner is an excellent choice for you. In order to improve the fermentation effect of organic fertilizer, we especially equip it with pallet and curved tooth blades. They are helpful for adjusting the moisture content and temperature of organic waste. So the material in the fermentation groove will get a suitable environment for better fermentation. Then let’s learn more about this compost machine.

Main Paramaters

- Turning width: 4000 mm

- Turning depth: 1000-2000 mm

- Turning Speed: 1900 mm/min

- Composting Time: 15-20 days

- Host Power: 18.5 kw*2

- Walking Power: 2.2 kw*2

- Equipment Material: Carbon steel

- Application: Chicken poop, cow dung,pig waste, biogas waste, mushroom waste, straw, rice hull, humus, etc.

Come to get more details of chain plate type compost turner!

When is it suitable to use chain plate type compost turning machine?

If you want to know whether the composter is suitable or not, you need to learn what occasion it is designed for. For the chain plate compost machine, it can be used in the following occasions:

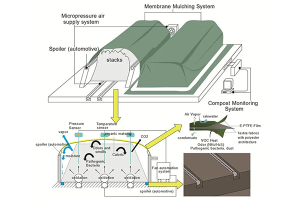

When you want to start organic waste compost in fermentation trench

When you select a compost machine, you must to decide what method you want to use in organic manure fermentation. If you want to make compost fertilizer in fermentation trench, chain plate compost turner is an ideal choice for you. During composting, it will move along the rails on the both sides of fermentation trench. Then the chain plate turning part will pick up the material continuously and transport it from the bottom of fermentation trench to a high point and then throw it down. In this way, material can fully contact with oxygen, which is beneficial for better aerobic fermentation of organic waste.

When you need a small scale compost machine

If you want to select a suitable compost machine for your organic fertilizer plant, capacity is also an item you must pay attention to. When you plan to start a small scale composting, you can choose chain plate compost turning machine. In general, it can be used for fermentation groove with a width of 3-4 m and a height of 2 m. And its working speed can reach 120 m/h. That is, SX chain plate type compost turner can help you process 400-500 ㎡ of organic manure per hour. This can fully meet your needs of small scale fertilizer compost making.

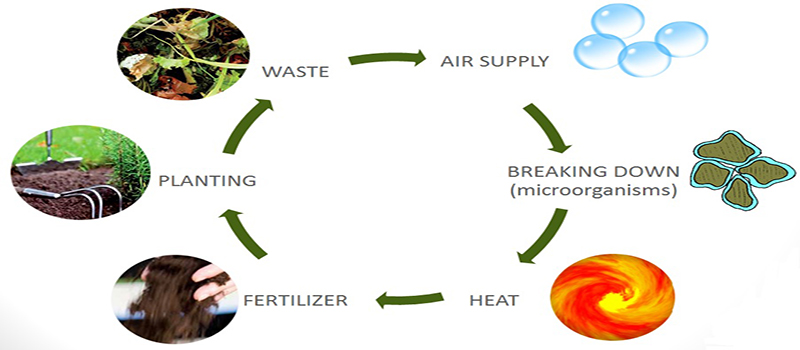

How does chain plate compost equipment work to compost organic fertilizer?

If you want to learn a fertilizer processing machine, the working process is an aspect you need to know. Then how chain plate composter works to finish the fermentation of organic materials?

Usually, the chain plate of this compost turner will form an angle of 45° with the bottom of the fermentation trench. When the equipment starts working, the chain plate will continuously and gradually pick up the material and transport it from the bottom of the fermentation groove to a high point and then drop it. This makes microorganisms in material get enough oxygen to decompose organic matter and materials dissipate its excessive heat. So you can finish organic waste composting better and faster. Then the dropped material will be piled up again and create a space for new materials.

What can chain plate type compost turner do for better organic manure fermentation?

The reason why we want to purchase a suitable compost machine is that we hope to make a better fermentation of organic fertilizer. Then how can chain plate compost machine help you achieve this purpose?

Make material get sufficient oxygen

As name suggests, aerobic fermentation is an oxygen consumption process. So a sufficient oxygen supply is indispensable for organic fertilizer composting. Chain plate type compost turner is designed with a chain plate turning system. It will transport material from groove bottom to a high position and throw down it. This makes material contact with air for a longer time, so it can get sufficient oxygen for successful fertilizer fermentation.

Break organic material cakes into smaller size

If you want to make better fermentation of organic manure, the small size material is better than big cakes. Because the smaller material size, the larger contact area with oxygen, the better fermentation effect. For this, we especially equip turning chain plate with 390 curved surface blades, which can greatly improve the crushing ability of the composter. In addition, the blades are made of wear-resistant steel and can be removed easily. So this machine can provide a service to you for a long time.

Provide suitable temperature conditions for composting

In composting, high temperature is the key to killing harmful substances in organic litter. But too high a temperature will damage the beneficial bacteria. So it is advisable to keep the temperature of material at 60℃-75℃. Here, chain plate compost machine can help you a lot. When it starts working, sufficient oxygen will enter into material to support the microorganisms to generate enough heat. At the same time, air porosity will increase to dissipate excessive heat quickly.

Why SX chain plate composter is so popular with compost fertilizer making plants?

There are a variety of compost turners in the market, why SX chain plate type composter earn the trust of customers at home and abroad? There are three reasons as follows:

High adaptability

SX chain plate composting machine adopts a working system of frequency conversion speed regulation. Therefore, it can adjust the speed of walking flexibly according to material resistance. This means that this compost machine can well adapt to the change of working load.

Turning with no dead angle

In order to create better fermentation effects of organic fertilizer, we also improve its moving system of turning part. It can not only lift freely vertically but also move horizontally. Therefore, it can turn material in the fermentation groove with no dead angle. Then you can finish organic fertilizer compost manufacturing in a shorter time.

Multi-groove composting

Combing with transfer vehicle, chain plate type compost turning equipment can realize multi-groove fermentation. That is, under the condition of the capability of the equipment, only by increasing the number of fermentation trenches, you can enlarge the scale of your organic fertilizer making business.

High degree of automation

It is designed with a fully automated electrical control system. So it can greatly reduce the cost of worker employment and make your compost production finish easier.

How to buy a suitable compost machine for you?

How long does it take to finish organic fertilizer composting with chain plate composter?

Generally speaking, under the help of chain plate compost turner, you can finish organic fertilizer composting within 20 days. These 20 days generally contains two parts: composting and aging.

Composting with chain plate type compost machine (7-8 days)

In this process, you need to mix organic waste with fermentation bacteria and auxiliary materials (with a water content of 50-60%). Then send them to the front end of the fermentation trench with a forklift. It is advisable to pile them into a stack with a height of 1.5-1.6 m. Then chain plate composter will turn material to help it quickly complete process of deodorization, harmfulness and dewatering. Then the processed material will be discharged from the fermentation groove. Usually, this period will take you 7-8 days.

Aging (10-15 days)

After leaving the pool, the materials should be transported to an aging area for storage. At the same time, it will finish the secondary fermentation, which can further decompose your organic fertilizer and remove excessive water from it. This period will take 10-15 days.