Achieving uniformity in fertilizer granules making is crucial for application efficiency and nutrient distribution. YUSHUNXIN enginners have 5 practical tips to produce produce fertilizer granules with consistent size:

Tips 1: Crushing raw material before fertilizer granulation

Begin with raw materials that make uniform particle size fertilizer. Use fertilizer grinder to crush compost or chemical materials into homogenous powder. As inconsistent particle sizes in the initial mix can lead to varied granule sizes. Uniformity in raw materials helps in achieving uniformity in the finished granules.

Tips 2: Moisture Control to make fertilizer granules better

In addition, the right moisture content is also essential for successful granulation of fertilizer. It allows powder to bind together effectively without becoming too wet or dry. Moisture levels typically range from 10-30%, depending on the granulation technology. The dry granulation machine require a below 10% moisture while wet granulation equipment needs a 20%-40% water content.

Tips 3: Granulation Equipment Adjustment Regularly

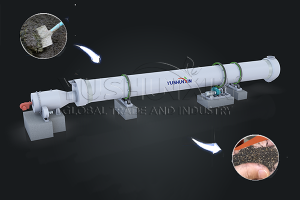

Calibrating your equipment for making fertilizer granules regularly. Whether you use pan granulators, rotary drum pelletizers or extrusion granulation machines. Parameters such as the disc angle, rollers gap, rotary speed and amount of binder solution, etc. Because, after a long period of fertilizer granulation equipment use, the equipment may has nuance. So you need to adjust it to ensure that you can produce fertilizer granules with with uniform size.

Get more about fertilizer granule making!

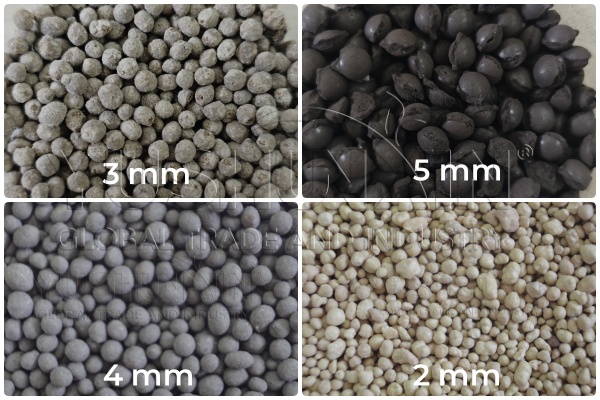

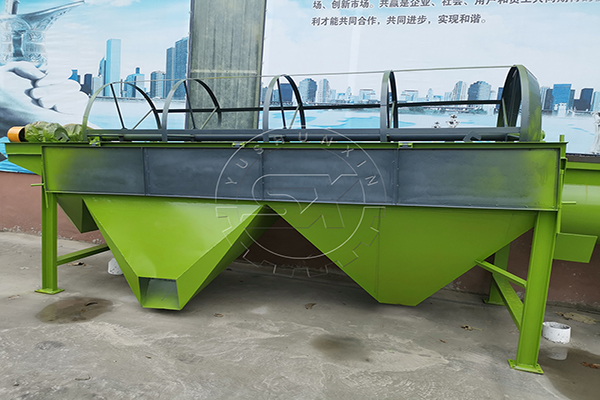

Tips 4: Screening out fertilizer granules with required size

After initial granulation of fertilizer materials, use a rotary screener or similar sieving equipment to separate the organic or NPK fertilizer granules by size. The oversized and undersized granules should be separated from the correctly sized granules. The off-size granules can then be crushed and recycled back into the granulation process to be reformed into the desired size.

To summarize, achieving uniform fertilizer granules production involves a combination of consistent raw material preparation, meticulous moisture management, precise equipment calibration and rigorous screening with efficient recirculation of off-size material. Control and attention to detail in each of these areas will result in the production of uniformly sized fertilizer granules, improving the product’s effectiveness and marketability.