Are you worried about what to do with the animal manure on your farm? Do you want to find the simplest organic fertilizer making line? Do you want to produce organic fertilizer at a low cost? SX powder fertilizer manufacturing line can fully meet your requirements. Only several steps, you can process organic waste into high quality organic fertilizer. And we will adjust the configuration of this system according to your actual conditions.

| Model | Powdery organic fertilizer making line |

| Capacity | 1-20 t/h |

| Configuration | Dehydrator, compost machine, loader type feeder, crusher, packaging machine, belt conveyor |

| Area | 800 – 5000 ㎡ |

| Price | $3,5000-$90,000 |

Get your own fertilizer making line now!

What is the process of the simplest organic fertilizer production method?

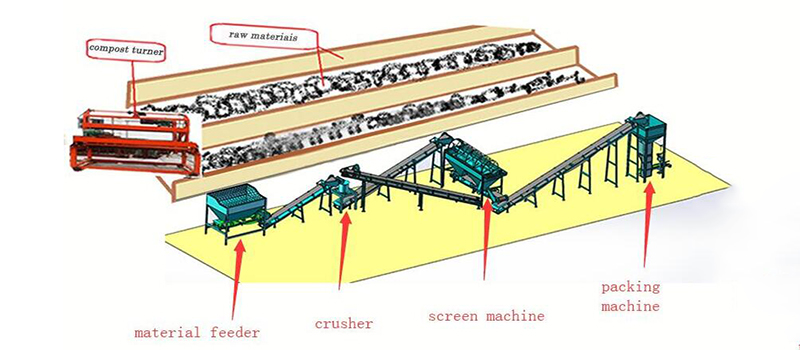

In general, our powder organic fertilizer making line can be divided into 5 parts. Composting, feeding, crushing, screening and packaging.

Dwatering

If the moisture content of your material is higher than 65%, it will influence the fermentation effect and reduce the quality. It is advisable to remove excessive moisture of material before composting. Here, our dewatering machine will help you a lot, it can reduce the water content of organic manure to 30%.

Composting

The fermentation is a necessary processing for organic fertilizer manufacturing. It will eliminate harmful substances and smelly odor of animal manure. Here, SX compost machine can help you shorten composting time and improve fermentation effect.

Feeding

In powder fertilizer making line usually feeds material by forklift feeder. Because it is equipped with a filter grid, which can filter the big waste in organic material. In addition, we design a stirring shaft and a vibration motor to prevent wall sticking and material blockage.

Crushing

In this process, fertilizer crusher will grind organic compost into fine powder. This is beneficial for the transport, storage and use of fertilizer.

Screening

This is a process to separate fine powder organic fertilizer from waste and agglomerate. This can improve the purity of your final fertilizer. Here, we especially design screener for powder fertilizer.

Packaging

This is the final step of this simplest organic fertilizer making line. Packing finished powder fertilizer in bags can make it convenient to store and transport fertilizer. This is beneficial not only for fertilizer manufacturers but for customers.

Is powdery fertilizer production line suitable for large scale organic fertilizer manufacturing?

Of course, although powdery organic fertilizer making system is simple, it has a wide application. Whether you want to prepare organic fertilizer from animal manure, industrial waste or aricultural litter, it can fully meet your needs. In addition, its largest capacity can reach 20 t/h. And the effect of finished organic fertilizer is also not weakened.

Why SX powdery organic fertilizer making line can reduce your cost on organic fertilizer production?

SX Powder fertilizer making system is popular with those who want to start a small organic fertilizer production at a low cost. Why? The reasons are as follows:

Fewer equipment

This system only needs 6 kinds of fertilizer equipment. To a certain degree, the cost of organic fertilizer making will decrease with the reduction of the number of equipment you use.

Long service life

All machines of powder organic fertilizer making line is made of high quality alloy steel, which is anti-corrosion and wear-resisitent. So it can work for you for s longer time and help you reduce the cost of equipment changing.

Less space occupation

In addition, because less equipment is contained in powdery organic fertilizer preparation line. Therefore, the space of it requires is smaller than other organic fertilizer preparation plans. So it will help you reduce the expense of factory rent.

Fully automatic

This design also can help you spend less on worker employment. Because it is a fully automatic organic fertilizer making project. Only by employing 2-3 workers, you can keep the whole powder fertilizer manufacturing system running continuously.

The above is a solution for the simplest organic fertilizer making line. Besides this, SX also can provide you with solutions for granular organic fertilizer making, no drying organic fertilizer production plan, etc. If you are interested in them, you can contact us for details. We will provide you with the best design and equipment according to your actual conditions.