Pollution control is an item you must focus on in fertilizer production. Whether you plan to start organic fertilizer making or NPK fertilizer manufacturing. Then as a professional fertilizer manufacturer, SX designs various pollution generation control methods for fertilizer preparation. It mainly contains two parts: composting gas waste collection and dust prevention. The following are the details of our designs for reducing pollution of fertilizer manufacturing:

What is the pollution control method during organic fertilizer composting?

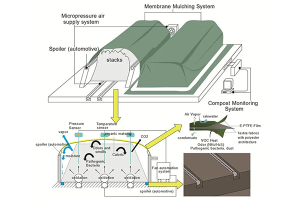

Composting is necessary for organic fertilizer production. But in this process, there is usually gas waste and bad smell generated. They will cause serious pollution to the surrounding environment. Can we start manure composting in an environmentally friendly way? For this, SX especially designs crawler type windrow composting machine and organic fertilizer fermentation tank.

- The former is equipped with a driving cab. It can not only isolate the bad smell of manure, but also keep the driver away from compost splash dust. So crawler type composter is greatly beneficial for protecting the health of composting worker.

- However, if you want to buy a more environmentally friendly composting machine, you can choose the latter. In-vessel fermentation equipment usually compost organic materials in a closed space. So the gas waste generated by aerobic fermentation does not diffuse to the outside to cause pollution.

- But how to dispose of the composting exhaust gas? We equip it with a special gas waste treatment system. It makes use of water to reduce dust and utilize activated carbon to absorb odor. In this way, you can prepare odor-free compost fertilizer.

Get more details of fertilizer making dust collector

Professional dust collection equipment in SX fertilizer manufacturing

In addition, we can also offer you professional dust collectors for your fertilizer manufacturing. Including cyclone dust collector, water curtain dust collector and dust fall room. You can choose them according to your needs.

Cyclone dust collector

In the process of fertilizer granules making, cyclone dust collect machine mainly makes use of centrifugal force to separate the waste dust with a density greater than the airflow from the airflow. Then, because of the inertia of airflow, the separated dust will attach to the inner wall of cyclone dust collector, and finally fall along the inner wall of the dust hopper under the action of gravity. This machine is widely used to separate particles with a diameter larger than 5-10μm. And its separation rate can reach over 80%.

Water curtain dust collector

Is there more effective dust disposal equipment for fertilizer making? Of course. You can buy our water curtain dust collector. As the name suggests, it mainly relies on water to reduce dust pollution of fertilizer production. In this way, it can even remove dust particles with a diameter of 0.1 μm.

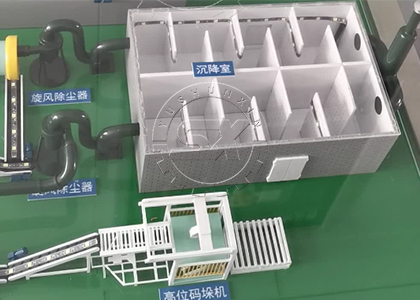

Dust fall room

Besides dust collectors, dust fall room also plays an important role in fertilizer manufacturing dust control system. There are a number of vertical baffles in dust fall room. When the gas flows through, it will change direction and reduce speed, and the contained dust particles will collide with the baffle and fall. So you can get gas which meets the discharging requirements.

Tips: In order to ensure the continuity of dust collection, it is advisable to clean dust fall room once a week!

The above fertilizer making dust collecting machines is commonly used after fertilizer drying. And they can help you reduce the dust content of discharging fertilizer making gas to 3-18 mg/Nm³.

What other pollution control methods are used in fertilizer production system?

Moreover, we can also equip belt conveyor and screening machine with dust covers. In this way, the the dust pollution generated by fertilizer making can be further decreased.