In today’s worlds, due to the needs of energy development and environmental protection, many counties and areas start setting up biodigestater for biogas production. But how to dispose of biogas waste? Leaving it alone will cause serious pollution to the environment. Here, SX can provide you with business plans for digestate to organic fertilizer. And there are many successful cases. For example, on 29th August 2023, a customer inquired about how to turn solid digestate into organic fertilizer in Uruguay. According to the actual conditions and requirements, we sent him a customized biogas waste fertilizer making line. The following are the specific details of this case:

Project overview

- Country: Uruguay

- Capacity: 60 TPD

- Material: 30,000 tons of manure waste and 60,000 tons of effluents per year

- Material moisture: 90%

- Solution: Powder organic fertilizer making

How to separate solid digestate from liquid?

For digestate to fertilizer project, moisture content adjustment is an item you must pay attention to. Like the client from Uruguay. The raw material from his biodigestater mainly consists of animal manure and effluents. Both have a humidity of 90%, which is not suitable for organic fertilizer production. Then how to dry biogas waste quickly? In this case, we recommend you use professional fertilizer dehydrator and inclined-screen solid-liquid separator is the best choice. It is specially designed for dry raw material with over 80% water content. With double dewatering designs of separation and pressing, the machine can help you separate solid digestate from the liquid quickly. And the moisture content of material can reduce to 30%-40% after dewatering.

Tip: If the moisture content of organic waste is between 50% and 70%, using screw type dehydrator is enough.

How to make solid digestate into organic fertilizer?

The final of purposes of the Uruguayan client is transforming the solid digestate into organic fertilizer. For this, SX can provide you with both powdery organic fertilizer production line and organic fertilizer granule making system. Considering the budget for organic fertilizer manufacturing from digestate, the customer decides to make solid biogas waste into powdery fertilizer. Its price is as low as $30,000. How to make solid digestate into organic fertilizer? There is a basic process for your reference.

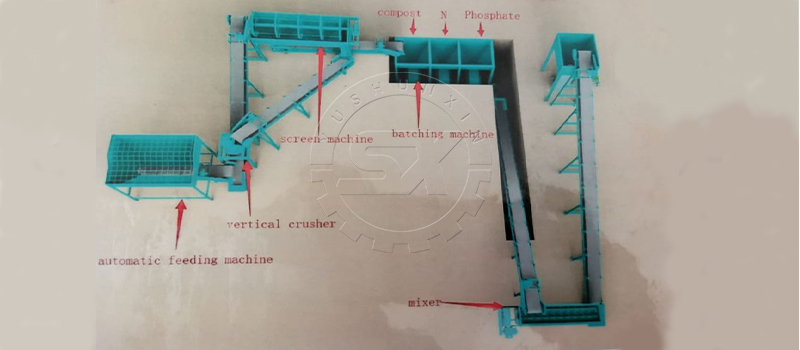

Tip: If you want to add other materials for enriching the nutrient of fertilizer you make, you also need two fertilizer machines. Multi-hoppers batching equipment for controlling the proportion of various materials and mixer to ensure nutrient balanced distribution.

What equipment is suitable for producing organic fertilizer from 6,000 m³ biodigestater waste?

But if you want to buy a suitable fertilizer making line for turning solid digestate into organic fertilizer, you also need to consider the capacity.

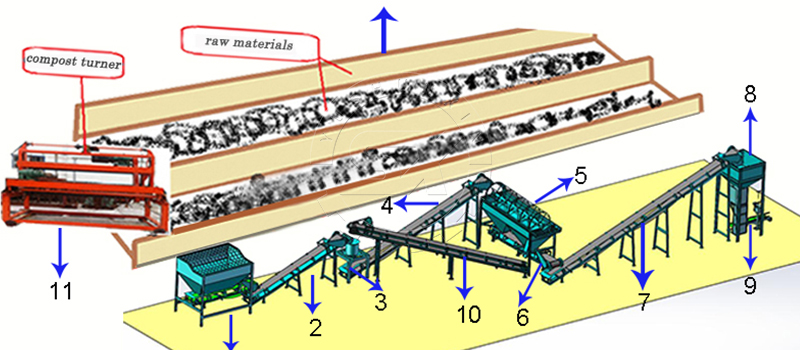

The Uruguayan client told us that the biogas project uses 30,000 tons of manure waste and 60,000 tons of effluents per year. Then because of 90% humidity. Your daily output of final organic fertilizer needs to reach 60 tons. Therefore, the biogas waste powdery fertilizer production line for the Uruguay customer consists of SXTSX-800 inclined-screen dehydrator, groove type compost turner, loader type feeder, SXFLF-600 vertical crusher, SXGS-1240 powder rotary screener and single bucket automatic bagging scale.

The above are details about our communication with the customer about how to make solid digestate into organic fertilizer in Uruguay. In addition, if you want to further to make digestate powder into pellets, we also can offer you various organic fertilizer granulation lines for your choice.