With the development of industry and agriculture, there is a lot of waste generated. Including animal manure, agricultural waste, industrial residue, biogas byproduct, etc. They will occupy a large space and pollute the environment. Using them as fertilizer is an excellent option to manage the waste. But many people don’t know how to process them into organic fertilizer quickly and easily. For this, YUSHUNXIN engineering equipment Co., Ltd can offer you professional organic fertilizer equipment and guidance. If you need them, please contact us immediately.

Main Parameters

- Capacity: 1-20 t/h

- Final shape: Powder or granule or liquid

- Final granule size: 1-10 mm

- Equipment types: compost machine, granulator, dryer, crusher, mixer, screener, packaging equipment, etc

- Application materials: animal manure, straw, rice husk, sawdust, mushroom waste, biogas residue

What equipment is needed in organic fertilizer making process?

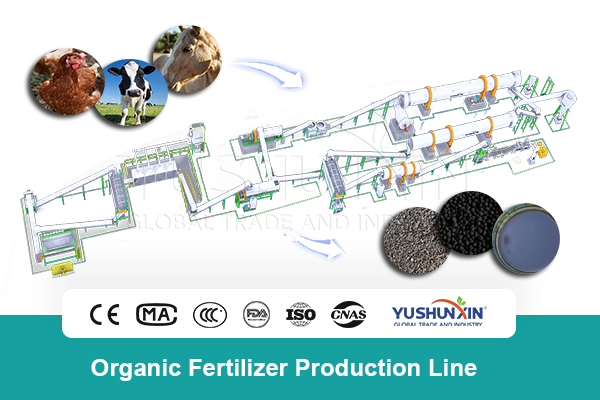

4 Main organic fertilizer production lines in YUSHUNXIN engineering equipment factory

Generally speaking, how to make organic fertilizer is depended on what organic fertilizer you want to produce? In this case, we especially design organic fertilizer systems of powder, granule, microbial and liquid for your choice. You can choose the best solution according to your needs.

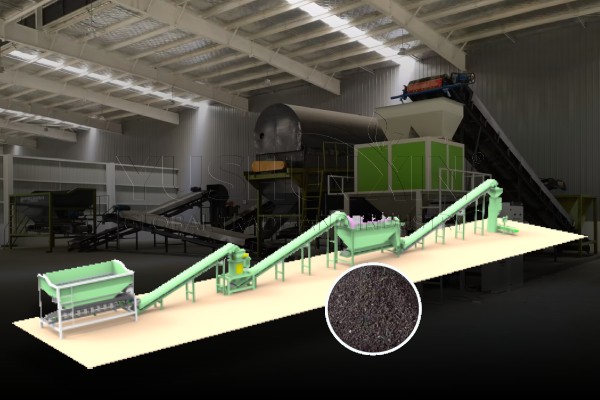

How to make powdery organic fertilizer?

If you need a organic fertilizer production line with a low cost, the production line of powdery organic fertilizer is your best choice. It is the simplest organic production line in YUSHUNXIN. It consists of composting machine, fertilizer feeder, crusher, powder screener, packaging equipment and conveyor. To a certain extent, less equipment means lower costs. Does it mean lower capacity? Of course not. The powdery organic fertilizer preparation line has a capacity of 1 t/h-20 t/h. If you use poultry manure as fertilizer, you can treat 30 -1,400 tons of poultry waste a day. So it is one of our hot sale organic fertilizer processing lines.

Powdery Organic Fertilizer Production Line

- Capacity: 1-20 t/h

- Product: Powder

- Design: compost turner, feeder, crusher, screen, packing machine, etc

- Equipment Material: Carbon steel Q235/Alloy

- Application: Cow dung/ chicken poop/ pig manure/ goat manure, etc

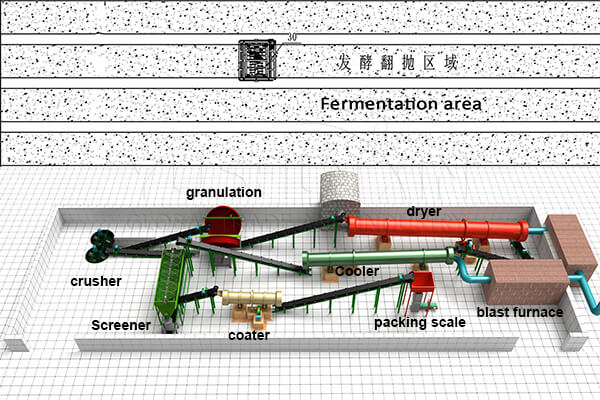

What is the technology of producing organic fertilizer granules?

Proveded you want improve your fertilizer quality, you can choose to make it into pellets. For this, we can provide you with the granular organic fertilizer production line. On the basis of the powdery fertilizer making line, it adds some other machines. For example, batching machine can be used to rich fertilizer nutrients and improve its proportion accuracy. Fertilizer mixer can fully mingle the materials again. The granulation equipment can turn powdery materials into pellets. Then the drying machine, cooling machine and coating machine will further process the particles. These machines will remove their water content and prevent nutrients loss. Therefore, the produced pellets are not easy to stick and more convenient to transport and store.

Granular Organic Fertilizer Production Line

- Capacity: 1-20 t/h

- Product: Granules

- Design: compost turner, batching machine, crusher, mixer, granulator, screen, dryer, cooler, packing machine, etc

- Equipment Material: Carbon steel Q235/Alloy

- Application: Cow dung/ chicken poop/ pig manure/ goat manure, etc to fertilizer

How to prepare bio organic fertilizer?

In addition, we also design bio organic fertilizer making system for you. Because of microorganisms adding, you can produce better organic fertilizer. For this, you can choose to prepare powdery or granule biofertilizer freely. However, the former, we recommend you add bacteria when mixing, while the latter, after drying. In this way, the microorganisms can fully play their roles. Then, for functional bacteria choosing, you can use Bacillus, Azotobacter, Actinomycetes, etc in the process of bio fertilizer production.

Bio Organic Fertilizer Production Line

- Capacity: 1-20 t/h

- Product: Powder or Granules

- Design: compost turner, batching machine, crusher, mixer, granulator, screen, dryer, cooler, coating equipment, packing machine, etc

- Equipment Material: Carbon steel Q235/Alloy

- Application: Cow dung/ chicken poop/ pig manure/ goat manure, etc

Can we make liquid organic fertilizer?

Then, how to dispose of liquid manure waste? You can turn it into liquid organic fertilizer. There is professional liquid fertilizer making system for you. It consists of separation, filtering, UV sterilization, auxiliary material batching, fermentation, sediment, filling, etc. High automation and stainless steel material use. Therefore, it can help you finish the production of liquid fertilizer making from manure slurry.

Liquid Organic Fertilizer Making system

- Capacity: 1-100 t/d

- Product: liquid

- Design: Liquid separator, filter, UV sterilization machine, material batching equipment, liquid reactor, sediment tank, liquid filling machine, etc

- Equipment Material: Stainless steel

- Application: biogas liquid, waste water from livestock and poultry

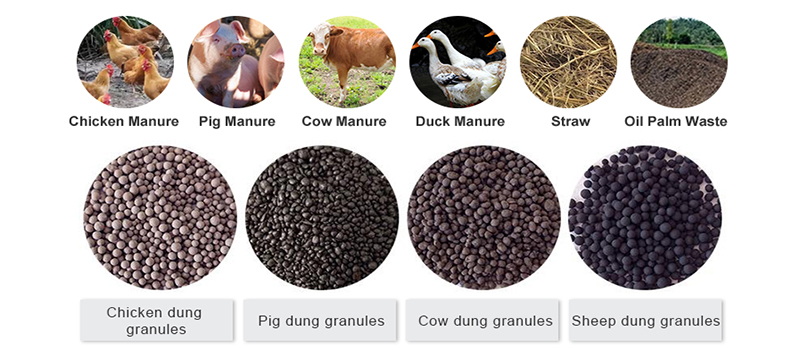

What raw materials can the system use in the production of organic fertilizer?

Materials preparation is the basis of making high quality organic fertilizer. In general, there are various materials can be used to produce organic fertilizer. Including animal manure, agricultural waste, industrial residue, biogas residue etc. Knowing more about them can make it easier to prepare organic fertilizer you need.

Which composting method is suitable for fermenting the above organic fertilizer materials?

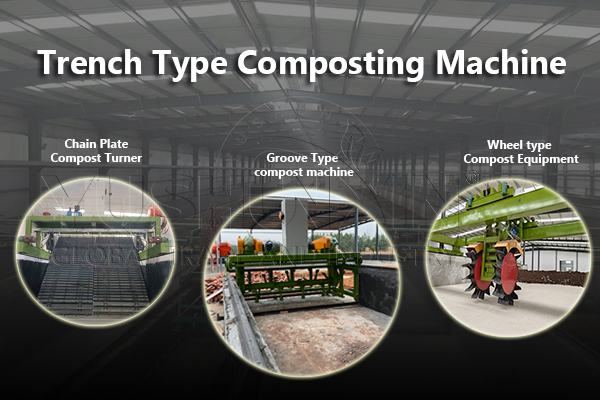

From the above, we can know that composting plays an important role in organic fertilizer manufacturingg. But how to compost organic waste quickly? Here, we recommend you use a professional compost machine. In general, you can prepare compost in 3 ways. Groove composting, windrow composting or in-vessel composting. You can choose according your needs. Whether you choose any method, we can provide you with correspondent fertilizer compost equipment with high quality.

Groove composting for both large and small scale compost production

If you plan to produce organic fertilizer in a large scale, we recommend you to choose composting materials in the trench. Because the largest compost trench you can build has a wide range of 30m and a depth of 3m. If you want to enlarge your organic fertilizer production scale, you only need to increase the number of trenches. Combining with the transfer vehicle, our compost turning equipment can be used for multiple-groove fermentation. In this case, wheel type compost turner is the optimal option for your large scale composting. Besides, for small scale composting in grooves, there are also groove type composter and chain plate composter all are ideal choices for you.

Windrow compost – no extra building

But if you want to compost fertilizer on the ground, windrow composting method is more suitable for you. During this process, you only need to pave the raw materials in long windrows and drive a windrow compost turner to turn them. Then you will get quality compost after 20 days. This compost method has features of low cost, high flexibility, easy operation, etc. If you are interested in this kind of compost making machine, you can choose crawler type compost turner and moving type compost turner to compost materials.

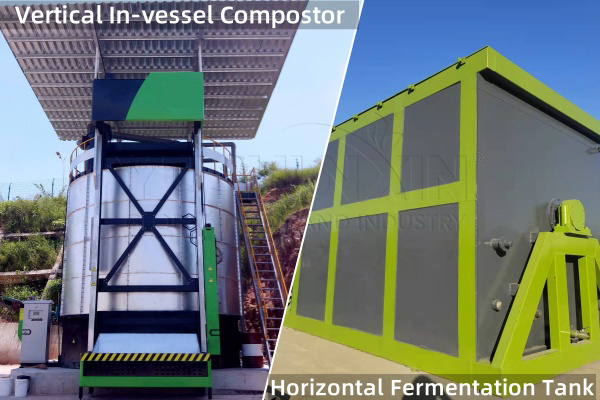

In-vessel composting for faster fementation

If you hope to ferment materials faster, you can choose in-vessel composting equipment. It adopts closed fermentation method. So only needs 10 hours, it can complete the harmless treatment process. Moreover, it is designed with professional gas waste recycling system, which meet your requirement of more environmentally fertilizer friendly composting. In addition, in order to meet the different requirements of customers, we design two types of fertilizer fermentation tank for your choice. They are vertical fertilizer compost pot and horizontal fermentation tank.

How to make organic fertilizer into pellets quickly?

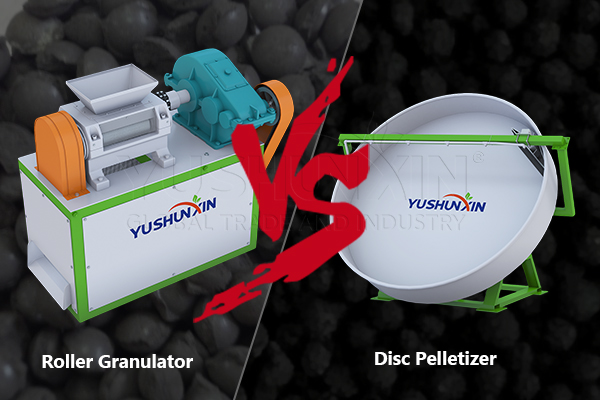

For turn organic fertilizer powder into pellets quickly, a suitable organic fertilizer granulation machine is indispensable. Generally, our company can offer you disc granulator, double roller pellet machine, new type pellet equipment and rotary drum granulator. They can fully meet your requirements for organic fertilizer granule manufacturing. For example:

Small scale organic fertilizer machine for pellets making

How to finish small scale organic fertilizer granules making better? Disc granulator and double roller extrusion equipment are both excellent choices. The former has features of 0.5-6 t/h capacity, over 93% granulation rate, economical price. The latter is better for organic materials with a water content lower than 10%. Then, with different extrusion rollers use, you can choose to produce organic pellets with 3-10 mm and shape of flat ball, oval, pillow, etc freely. In addition, a double roller press machine can prepare 1-3 tons of compost powder into organic fertilizer pellets quickly.

1-8 t/h compost to pellet equipment

However, if you want to prepare organic fertilizer granule with a high hardness, it is advisable to buy a new type organic fertilizer granulation equipment. This machine mainly makes use of the friction between stirring teeth and equipment wall to granulate organic manure. So the produced fertilizer pellets have a high harness, which is beneficial for transport and using. This is also the reason why it is also known as stirring teeth granulator. Its output is 1-8 t/h, it is enough for small and medium scale organic fertilizer plant use.

Industrial organic fertilizer pelletizer with a large capacity

But for large scale industrial organic fertilizer granule making, more fertilizer manufacturers prefer to rotary drum granulator. Its largest capacity can reach 30 t/h. How about the granulation rate? Over 90%. Can it withstand the corrosion from the large scale manure materials process? Of course. We especially add rubber lining and cleaning holes to it. The former has a high performance in erosion resistance. While the latter can prevent material sticking to the equipment wall and reduce the erosion. Only need to hit cleaning holes with a hammer, the sticking materials will fall.

3 Things you must know during the process of making organic manure

If you want to prepare high quality organic waste fertilizer, you must pay attention to these 3 aspects.

Best Moisture content for organic fertilizer manufacturing

Keep the moisture content at the right level is the secret of improving final organic fertilizer quality. There are different requirements for water content at each stage.

Before compost making, the moisture content must not exceed 65%. If it exceeds, you can use the following two methods to reduce it. For one thing, you can use fertilizer dewatering machine to remove excessive water For another, you can add straw, branches or leaves to absorb the water. After doing this, the moisture will be reduced to 60%.

Then, composting can decrease this number to 30%-45%. It is an ideal moisture content for making powdery fertilizer into pellet. After granulating, the moisture content will become lower, about 15%-20%. But the standard of organic fertilizer is 14%. At that time, dryer and cooler are excellent partners for you.

If you need to increase moisture content when manufacturing organic fertilizer. Our equipment can also meet your requirements. Some SX fertilizer machines can be equipped with spray devices for easier water adding. Such as groove type compost turner, windrow compost turner, disc granulator , rotary drum pellet machine, etc.

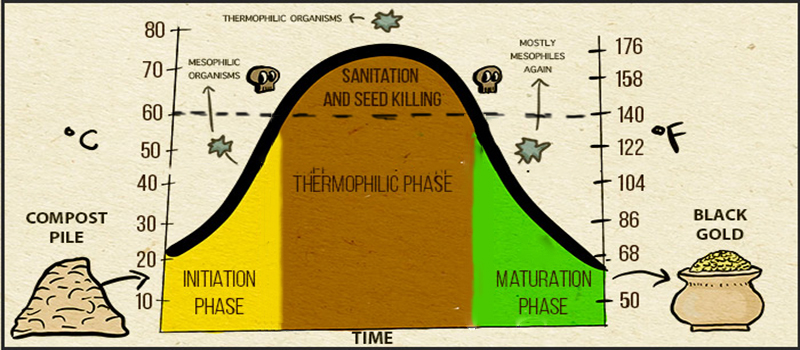

What is the opptimal fermentation temperature

Why we need to compost organic material? Because it has a bad odor and contains many pest eggs. During compost making, the high temperature will kill harmful bacteria and pest eggs. So it will not affect crop growth. And the most optimal fermentation temperature is between 65℃ and 70℃. Our composting equipment can finish it easily.

How to produce uniform size fertilizer by screening

Screening is the key to separating qualified and unqualified fertilizers. According to actual needs, our engineers design two types of fertilizer screeners. Powdery screening machine and granule screen machine. The former can separate finished fertilizer powder and waste. The latter can divide manure particles into three parts. Small pellets and fine powder, 3-5 mm particles, and large granules. After screening, the unqualified pellets will be returned to crush and make into pellet again.

What is the cost of organic fertilizer production?

The lastest feedback of YUSHUNXIN organic fertilizer making lines

Over the past more than 20 years, many organic fertilizer manufacturers start their making plant with YUSHUNXIN fertilizer equipment. They all give a good feedback.

“The pan granulation line can produce organic fertilizer pellets in uniform size quickly. Then, what surprised us even more was its 93% granulation rate and favorable price. Thank you very much for your recommendation to our organic fertilizer plant in south africa.”

“It works good. The in-vessel fermentation tank can compost fertilizer year-round in Russia effectively. Then, there is no ordor pollution. It is helpful to disposal the manure waste in our farms! Thank.”

“The liquid fertilizer production line in Australia is working very well. It can quickly process poultry manure on our farm into liquid fertilizer that can be sold. Thank you very much for your help in the installation and use of the equipment.”

Why to choose YUSHUNXIN fertilizer equipment factory as partner

YUSHUNXIN is the leading fertilizer equipment manufacturer in China. In addition, it has nearly 20 years of experience in the production of organic and compound fertilizer equipment. So it can provide you with high quality fertilizer equipment at the best price. In addition, we can offer you the best service. Including free project design, featured customization machine and considerate after-sales service.