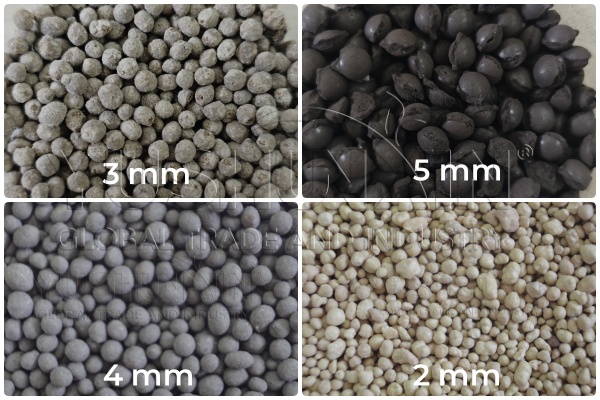

When you start granular fertilizer production, it is necessary to decide what size of pellet you want to prepare. Small or large? The smaller size, the faster nutrients supply to crops, the effect more obvious. The larger size , the more convenient transport, the slower nutrients release, the longer fertilizer effect. Then, how to change the size of fertilizer granules during granulation? The answer is as follows:

Which granulator is suitable for making your own fertilizer?

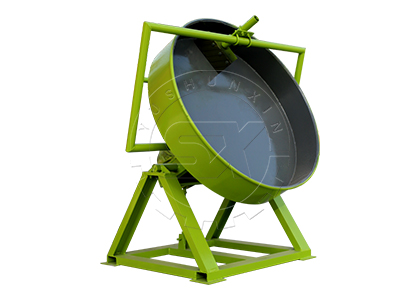

How to regulate fertilizer pellet size when using disc granulation machine?

Disc granulator is an ideal choice for economical small scale fertilizer pellets making. It can fully meet your requirements for 1-8 mm granular fertilizer production. In general, you can control the particle size by 2 ways.

Adjust the moisture content

The higher moisture content, the larger size; the lower moisture content, the smaller size. Why? The high water content makes materials easier to stick to each other and combine with more materials. So it is easier to roll into larger fertilizer granules.

Change the angle of disc

The sharp slope, the smaller size; the slower slope, the large size. However, what you need to focus on is that it is advisable to keep the angle of disc between 35° and 55°.

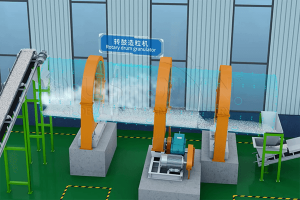

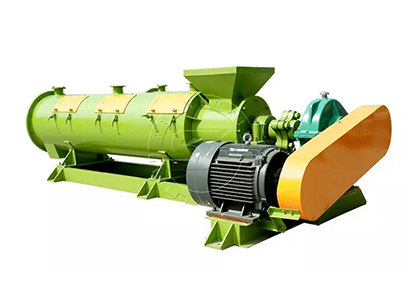

How to adjust fertilizer particle size when using rotary drum granulator, new type organic fertilizer pelletizer and rotary drum churning granulation equipment?

As for rotary drum granulator, new type organic fertilizer pelletizer and rotary drum churning granulation equipment, you also can regulate fertilizer pellet size by controlling water content. In addition, it is also an excellent choice to adjustthe rotating speed of drum or stirring shaft.

Adjust the water content

The higher water content, the larger size; the lower water content, the smaller size. But during granulation, the water content must be kept between 20% and 45%. This is the optimum moisture content for fertilizer pellet making.

Change the rotating speed of drum or stirring shaft

The higher rotating speed, the smaller size; the lower rotating speed, the larger size.

Learn more about the fertilizer pellet making!

How to change the size of fertilizer granules when using double roller extrusion granulator?

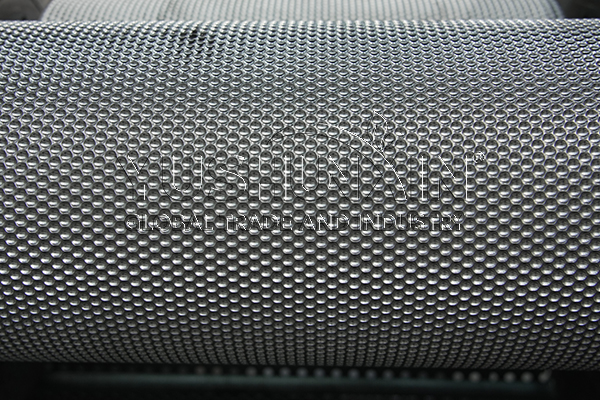

When you use double roller pellet making equipment to granulate NPK fertilizer powder. You can regulate pellet size by choosing the mold with required size ball socket. SX can provide you with mold for preparing fertilizer pellets with a diameter of 3-10 mm.

Inquiry the double roller press granulator!

How to adjust the size of fertilizer pellet when using flat die pelleting equipment?

But if you plan to start fertilizer granulation with flat die granulator, choosing mold with required size holes is the best way for you to produce the fertilizer particles you need. And in SX, there are various molds for your choice, from 2mm to 10mm.