When you start organic fertilizer production, space occupation is an item you must focus on. Because it plays an important role in organic fertilizer equipment choosing and organic fertilizer plant design. Then how many work area does organic fertilizer production need? You can get an answer from this post.

Get the specific area occupation of your organic fertilizer making line

How many parts does an organic fertilizer making system contain?

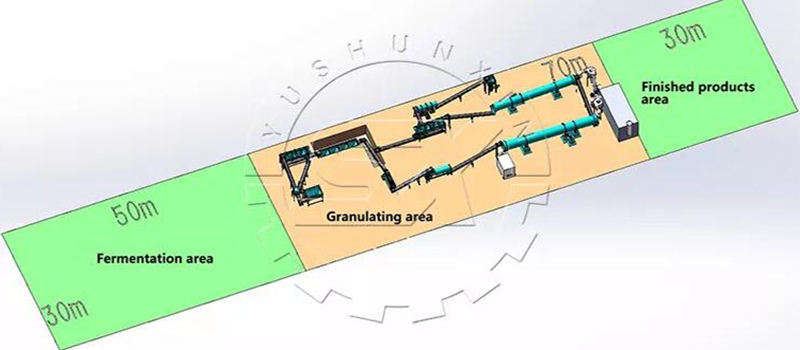

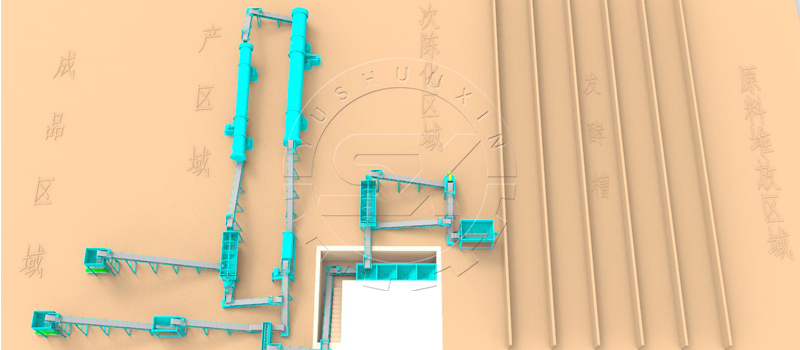

Before estimating the area occupied by your organic fertilizer production line, you’d better understand how many parts it contains. In general, an organic fertilizer manufacturing factory consists of 4 parts as follows:

- Materials area: It is only used for the temporary storage of livestock manure and auxiliary materials like straw. If it does not rain often, you can put it in the open air place.

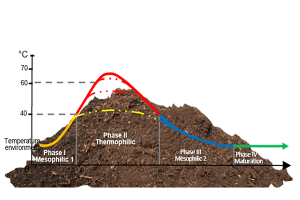

- Composting area: As its name suggests, you will compost organic waste in this area. You can choose to build fermentation grooves or make aerobic fermentation of manure directly on this flat ground. In addition, it also contains space for compost fertilizer aging.

- Organic fertilizer making workshop: This area is prepared for installing machines which can turn compost into power or granular organic fertilizer. Such as crusher, mixer, granulator, drying machine, etc. It is advisable to build a workshop with a height of 6 m for the area. It can reduce the wear of organic fertilizer equipment and prolong its service life.

- Finished organic fertilizer products area: This is a place of finished organic fertilizer products storage.

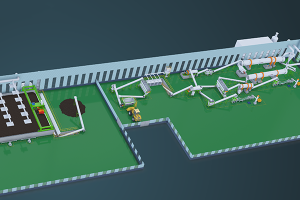

How to set up a organic fertilizer manufacturing plant?

How much space does an organic fertilizer production line require?

To be honest, it is not fixed. Because the work area of an organic fertilizer manufacturing system is affected by many factors. Such as capacity, equipment number, final fertilizer shape, etc. There are some examples for your reference.

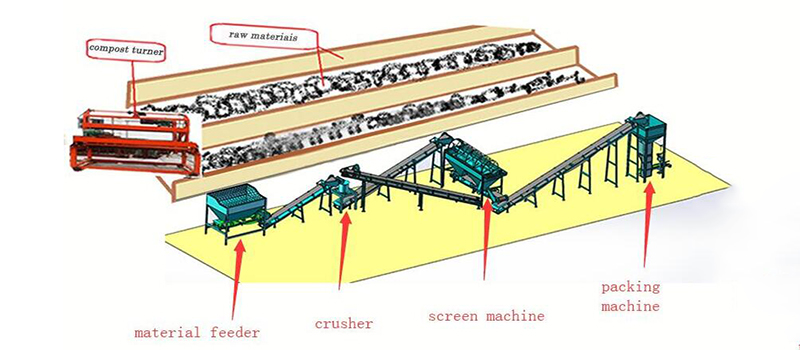

1-5 t/h small scale powdery organic fertilizer making line

- Configuration: Fertilizer compost turner, feeding machine, semi-wet crusher, screening machine, packaging machine, belt conveyor

- Area occupation: 800-1,500 ㎡(about 0.2-0.4 acres)

10-20 t/h large scale powder organic fertilizer production system

- Configuration: Fertilizer compost turner, feeding machine, vertical pulverizer, screening machine, packaging machine, belt conveyor

- Area occupation: 3,000-5,000 ㎡(about 0.8-1.3 acres)

1-5 t/h small scale granular organic fertilizer manufacturing line

- Configuration: Fertilizer compost machine, batching machine, semi-wet crusher, powder screener, batching machine, stirring tooth granulator, dryer and cooler, granules screening machine, coating machine, packaging machine, belt conveyor

- Area occupation: 2,000-4,500 ㎡(about 0.5-1.2 acres)

10-20 t/h large scale granular organic fertilizer preparation system

- Configuration: Fertilizer compost machine, batching machine, vertical crusher, powder screener, batching machine, rotary drum granulator, dryer and cooler, granules screening machine, coating machine, packaging machine, belt conveyor

- Area occupation: 5,500-10,000 ㎡(about 1.4-2.5 acres)

The above data is for reference only. If you want to know the specific area occupation of your organic fertilizer making line, you can contact us directly by following contact form.