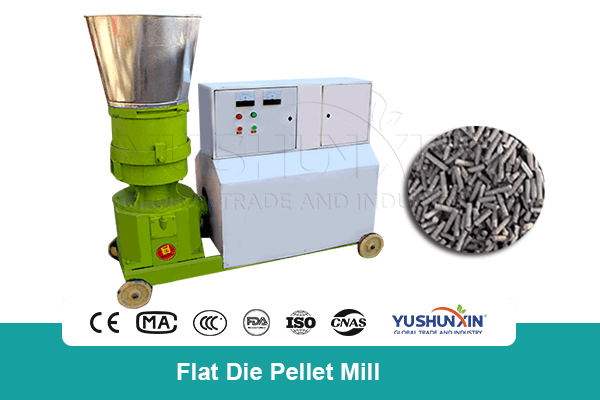

Flat die pellet mill is a kind of popular organic fertilizer granulating equipment, because of economical price and high granulation rate. Especially for small scale organic fertilizer making. It usually can produce 1-2.5 tons of particles per hour, that is, you can get about 6,000-15,000 tons of organic fertilizer a year. But, the unit price is only $3,000-$7,000. In addition, YUSHUNXIN flat die granulator is also an ideal choice for feed pellet making and wood pellets production.

Main Parameters

- Capacity: 1-2.5 t/h

- Granule Size: 2-10 mm

- Pellet Shape: Column

- Granulation rate: 95%

- Feeding Material Moisture: <15%

- Equipment Material: Q235 Carbon Steel

- Application: Organic compost, Feed, wood waste, sawdust, etc

What is the working principle of organic fertilizer flat die granulating machine?

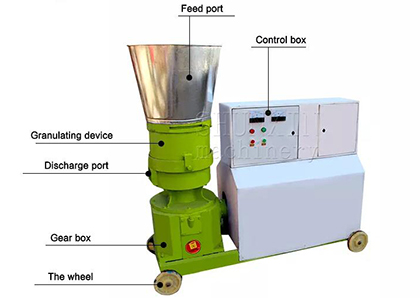

If you want to use flat die pelleting mill freely, it is necessary for you to understand the work principle of it. The flat die granulator employs dry extrusion granulation method, which processes organic fertilizer powder into granules without water involving. It completes organic fertilizer granulation mainly by the extrusion force between rotating roller and mold. Here, you need to pay attention to the moisture content of your material and it is advisable to keep it less than 10%.

Is there a more detailed explanation of this process? Of course.

- First, after feeding the organic litter into flat die pelletizer, the rotating roller will rotate and press raw material in the mold.

- Because there are many column holes in mold, the pressed material will be turned into long cylindrical pellets.

- Then the inner shearing knives will cut them into granules with proper length.

- Finally, the finished organic fertilizer particles will be discharged from the outlet.

Why flat die pellet mill can help you make organic fertilizer at a low cost?

The flat die fertilizer pellet making equipment is popular for small scale organic fertilizer making. Because it can help you make 1-5 tons of organic fertilizer granules at a low cost. This is obsvious in equipment price, larbor force cost, land investment, low maintenance cost, etc.

Flat die pellet mill price $3,000-$6,000

Because of small capacity and smiple design, the quote of a flat die fertilizer granulator is economical. Only $3,000-$6,000 per set. But, it can fully meet your requirements for 1-2.5 t/h organic fertilizer pellets manufacturing. At the same time, the fertilizer granulation rate can reach 95%.

| Model | Capacity (t/h) | Power (kw) | Pellet Diameter (mm) |

|---|---|---|---|

| SXPM-400 | 1-1.5 | 30 | 2-10 |

| SXPM-500 | 1.5-2 | 37 | 2-10 |

| SXPM-600 | 2-2.5 | 45 | 2-10 |

Get precise quote of your flat die granulator!

1-3 Workers Operation

The easy operation of the flat die granulator can decrease the cost of worker employment. This machine is controlled by an electrical system, only one worker is enough to operate this granulator. And only 3-5 workers, you can keep the whole organic fertilizer production line with flat die pelletizer running. This greatly contributes to reducing the cost of labor force.

Inquiry your flat die granulation system now!

Adopt dry granulation method

This flat die granulating equipment employs dry extrusion granulation method, which has no need of water involving. Therefore, it doesn’t need subsequent drying and cooling processes. This can help you save the money spent on dryer and cooler buying and fuel consumption.

Long service life

This organic fertilizer granulating mill also has a characteristic of long service life, because all SX fertilizer machines are made of anti-corrosion and wear-resistant alloy steel material. Long service life usually means that you don’t need to change the machine frequently. So you will spend less on granulator changing.

Less space occupation

Compared other organic fertilizer pelleting machines, flat die pellet mill occupies a smaller space. So you can reduce the budget for factory rental.

How to regulate the flat die granulation pellet size and shape?

If you want to know whether this granulator is suitable for your organic fertilizer plant, the specification of granule is also an item you need to focus on. Flat die pellet mill can help you produce columnar particles with a diameter of 2-8 mm. But different customers may have different requirements. How to adjust the size and shape to meet your requirements during flat die granulation?

How to regulate the size of fertilizer particles

If you make organic fertilizer into granules with flat die pelletizer, you can change fertilizer size by choosing different molds. As mentioned above, the flat die pelleting machine produces granular fertilizer by pressing material into mold. In general, this size of produced fertilizer particle refers to the diameter of the cut surface of the hole in the mold. Here, SX can provide you with suitable mold for preparing fertilizer with any diameter within 2-8 mm.

How to convert the pellets into round fertilizer

The organic fertilizer particle manufactured by flat die granulator is columnar. But sometimes, you may want to convert them into round pellets. How to finish this task? Fertilizer polishing machine can help you a lot. This equipment is designed for reprocessing granular fertilizer particles with other shapes into spherical granules. And it also can help you improve the appearance of your fertilizer and make it more competitive. And in order to meet different needs of customers for capacity, we especially design two- stage polishing machine for small scale fertilizer production and three-stage polishing equipment for large scale fertilizer manufacturing.

What is the difference between flat die pelletizer and double roller granulator?

Flat die pellet mill and double roller granulator both adopt dry granulation method, what is the difference between them?

Applicable fertilizer type

If you plan to produce compound fertilizer pellets, we recommend you choose double roller pelletizer. However, when you need a granulating for organic fertilizer processing, flat die pelleting equipment is an ideal choice for you.

Produced pellet shape

The final particles prepared with double roller granulating machine are spherical. But the fertilizer processed with flat die granulator is columnar.

Structure

Although these two pelleting machines both employ dry extrusion granulation method. They complete it in different ways. Double roller pelleting equipment mainly makes fertilizer granules by extrusion force between two parallel cylindrical rollers. But flat die granulator mainly relies on the rotating roller and mold to generate the extrusion force.

Capacity

Provided you need a smaller granulator, it is advisable to choose flat die pelletizer. When you need a larger pelletizer, you can choose double roller granulator.

Price

If you want to finish fertilizer granulation at a low cost. These two pellet making machines are both excellent choices for you. But the flat die pelleting equipment is the most economical one of fertilizer pelletizers on sale at present.

Things you must focus on when using flat die granulating machine

Flat die granulator plays an important role in small scale organic fertilizer granulation. In order to ensure it can be used for a longer time and improve the production efficiency of organic fertilizer. It is necessary to understand how to use it in the right way. There are some tips for your reference.

- Before starting the machine, you need to do a good job of checking whether the parts are loose or not. If not, you can start the motor. And after the motor reaches a certain speed, you can feed materials in it.

- During the operation, if the flat die granulator is blocked. You must cut off the power first and clean the stored materials in the granulator. Then you can start repairing it.

- Lubricate regularly, especially for wear parts such as bearings. In general, bearings are normally lubricated monthly. But in adverse conditions, you need to lubricate the machine every week.