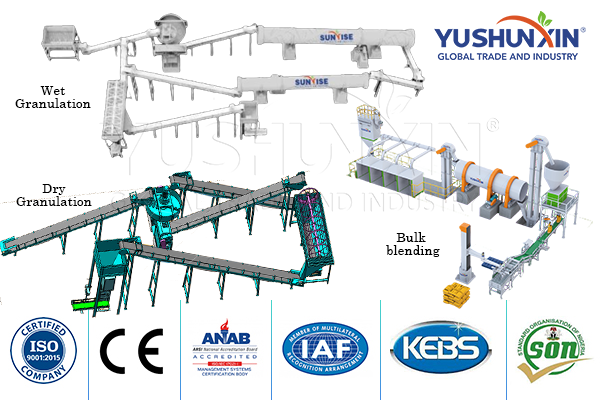

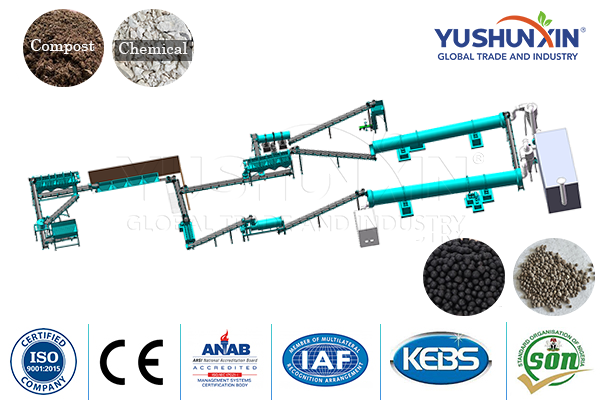

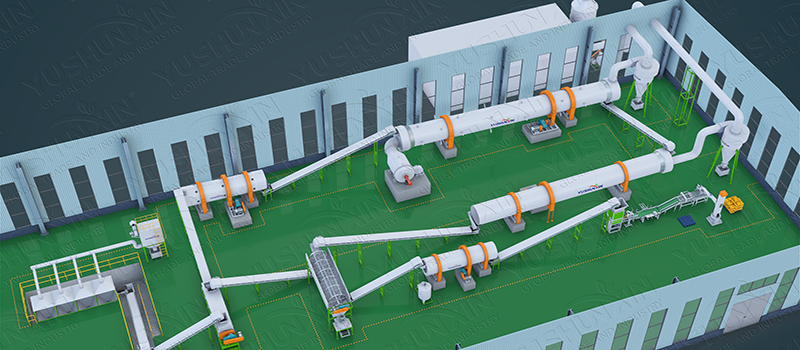

NPK fertilizer making machine, as the name suggests, is used in converting chemical materials into compound fertilizer with a certain proportion of nitrogen, phosphorus, potassium. Here, YUSHUNXIN can provide you with all equipment for a complete NPK fertilizer making line. Including batching machine, crusher, pellet equipment, dryer, cooler, packing machine, etc. Then according to your actual conditions, we will design the customized NPK production project with econonical price for you.

Main Parameters

- Capacity: 1-20 t/h

- Type: Granulator, batching machine, crusher, mixer, dryer, cooler, packing machine, etc

- Quipment Material: Carbon steel Q235/Alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: Making fertilizer from urea, ammonium chloride, superphosphate, potassium chloride, etc

Learn more about NPK fertilizer plant setup

What equipment is needed in industrial NPK fertilizer production process?

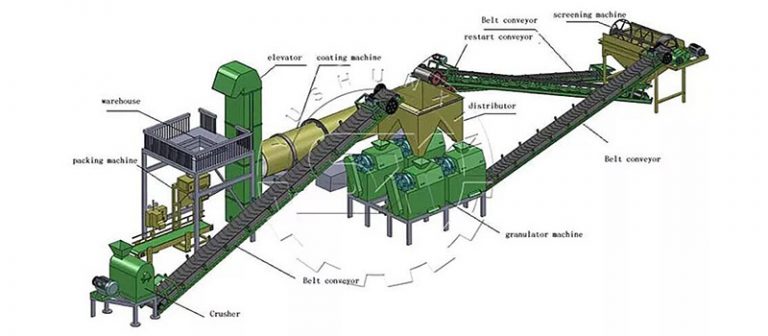

Generally speaking, a complete NPK fertilizer making line contains equipment as follows:

Batching machine

As mentioned above, NPK fertilizer is a kind of compound fertilizer with a certain proportion of N, P, K. And this proportion important to make your unique NPK fertilizer. Then how to prepare NPK fertilizer with required ratio? Batching machine can help you a lot. With nulear scale and electricity scale, you can feed N, P, K materials in precise weight. And we can add material hoppers according to your requirements. 1-4 or more.

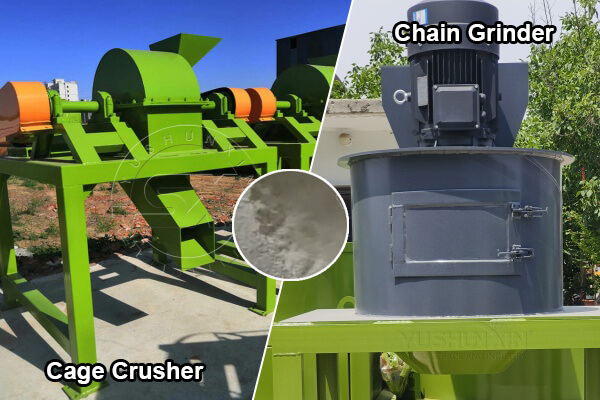

NPK Crusher

Then crushing machine is also essential for NPK compound fertilizer making, especially the NPK granulation process. For one thing, it can large particles and agglomerated chemical materials into fine powder, which is beneficial for better NPK granulation. Like cage crusher, which is designed for compound fertilizer making. For another, there is also crusher for granulated NPK fertilizer recycling. This can greatly reduce the material waste. Such as chain grinder.

Granulation machine

This is a NPK fertilizer making machine you must focus on. Making NPK powder into fertilizer pellets is an excellent choice to make more business profits. Because granulated NPK usually has lower possilibility of sticking, slower release and longer storage time, etc. Then for equipment for NPK pellets making, there are top 3 models for your reference. Small scale disc pelletizer, large drum granulator and economical roller extrusion machine.

Granular screener

During this process, rotary screening machine will differentiate between qualified and unqualified NPK pellets. Then the unqualified to re-granulate. This can prevent your NPK fertilizer manufacturing from material waste. So you can get a more economical NPK fertilizer making system.

Dryer and cooler

If you prepare NPK fertilizer with wet granule making equipment, the dryer and cooler are necessary. Because it can remove excessive moisture from your NPK fertilizer granules, its quality can be further improved.

Coating equipment

Coating machine will form a protective film on the surface of your NPK fertilizer pellets. The protective film can isolate fertilizer particles from the outside world. Therefore, your final NPK profuct is not easy to stick again and will have a longer fertilizer effect.

Packaging equipment

Packaging is the last procedure of the whole NPK fertilizer production line. It is dispensable if you make fertilizer for your own use. But if you want to sell it to others, it can improve the competitiveness of your fertilizer products.

What need to consider when you buy NPK fertilizer making machines?

After understanding what equipment you need for NPK fertilizer making, you also need to pay attention to how to purchase suitable NPK fertilizer manufacturing equipment. Then for NPK equipment selection, you can consider it from the following items:

Capacity

Capacity is an item you must pay attention to when selecting NPK equipment. For example, when starting a small scale NPK fertilizer processing, we recommend you choose SXLTF-600 single chain crusher, disc granulation machine, etc. And for large scale NPK making, it is advisable to buy SXLTF-800 double chain grinder, rotary drum pelletizer, etc.

Budget

In addition, most customers are concerned about the cost of NPK fertilizer machines. Taking pellet machines as an example. If you want to spend less, disc granulator and double roller pelletizer are ideal choices for you.

Processing method

Moreover, processing method is also an important factor that affects your NPK processing equipment selection. Provide you use wet granulation method, it is necessary to buy dryer and cooler for excessive moisture removal. However, when you use dry granulation machine for NPK pellets making, it is dispensable to purchase dryer and cooler.

Which granulation machine is best for your NPK fertilizer making plan?

Granulation plays an important role in NPK fertilizer manufacturing process. However, fertilizer suppliers usually have different requirements for NPK compound fertilizer granulator. For this, we especially design various pellet making machines for your choice. Including:

Disc pellet making machine for small scale NPK fertilizer making

If you meed a granulation machine for small-medium scale NPK fertilizer manufacturing, we recommend you choose disc pan granulator. There are two reasons. For one thing, it has a capacity of 1-6 t/h, which meets your requirements of small scale NPK compound fertilizer pellets processing. For another, it also has characteristics of low cost and less area occupation. They are exactly what small scale NPK fertilizer production manufacturers need.

Rotary drum granulator for large scale NPK fertilizer manufacturing

But when you want to start NPK powder pellet production in a large scale, rotary drum pelletizer is your best choice. The largest output of this compound fertilizer pellets making equipment can reach 30 t/h. But the power of the largest capacity drum granulation machine is only 37 kw. Which is lower than other large scale NPK fertilizer granulators. Therefore, you can finish large scale NPK granule making at a lower cost.

Double roller pellet machine for dry NPK fertilizer granulation

The above two pellets making machines both belong to wet granulation machine, is there NPK pellet machine for dry granulation method? Of course. Double roller extrusion granulator is designed for low moisture granular NPK production. It mainly makes use of the extrusion force between two rollers to convert powder chemical materials to particles. So there is nearly no water involved and subsequent drying and cooling steps are also not needed. Then you will spend less on NPK fertilizer machine buying.

How much does SX NPK fertilizer equipment cost?

Generally speaking, the price of NPK machines is not fixed. Because it is related to NPK fertilizer making scale, project design, equipment types, etc. From the data of our past cases, the cost of an NPK fertilizer preparation system is as follows:

1-5 t/h NPK fertilizer making machine

Usually, small capacity means a low investment in NPK fertilizer machine buying. For example, when you plan to produce 5 tons of NPK fertilizer pellets per hour, you may just need to invest in $8,000-$50,000.

5-10 t/h NPK fertilizer production equipment

When you want to buy equipment for your 5-10 t/h NPK manufacturing plant, you may need to prepare about $25,000-$100,000 for this medium NPK fertilizer making project.

10-20 t/h NPK fertilizer processing mill

For large scale NPK fertilizer production machines purchasing, you usually need to invest about $50,000-$150,000. But it will provide you with more profits after setting in motion.

Is there NPK fertilizer plant running?

Of course. At present, we have help many NPK fertilizer manufacturers to start their business and make profits. In Turkey, Australia, Pakistan, Indonesia, India, America, etc. There are some NPK manufacturing project designs for your reference and some hot selling plans from the feedback of our past customers.