On 10th February, 2025, a client from Zambia asked us about the solution of organic fertilizer plant costs $300,000. He plan to recycle animal manure waste as material to make organic fertilizer and consider to add phosphate rock materials. 20 T/H capacity, 3mm particle size, the budget of the organic fertilizer making project is $300,000. The following are the specific details of communication in this case:

Project Overview

- Country: Zambia

- Capacity: 20 T/H

- Budget: $300,000

- Requirement: Organic fertilizer making

- Solution: 5 t/h organic fertilizer granulation line + 15 t/h powder organic fertilizer production system

What is the best solution to setup a organic fertilizer plant costs $300,000 in Zambia?

The Zambian customer required a 20 T/H organic fertilizer plant established with a $300,000 investment.

For this, the best solution is a system which consist of a 5 t/h organic fertilizer granulation line and a 15 t/h powder organic fertilizer production system. In this way, you can only make high profits by organic fertilizer pellet making, but also get fast return by powder organic fertilizer manufacturing.

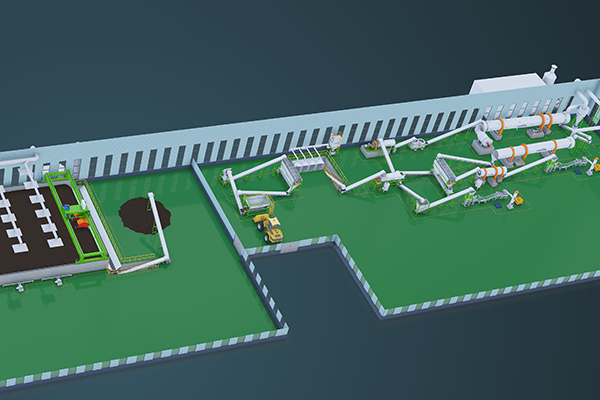

What is the design of the organic fertilizer plant costs $300,000?

For one thing, you can choose to setup the two organic fertilizer making lines separately in the organic fertilizer plant. As follows:

5 t/h organic fertilizer granulation plan design

To setup s 5 t/h organic fertilizer granulation line, it usually consist of 9 fertilizer machines. Including groove type compost machine, dynamic fertilizer batching equipment, SXSF-90 semi-wet material crusher, double shaft horizontal mixer, organic fertilizer granulator, SXGS-1240 rotary screener, SXHG-1515 rotary drum dryer and cooler, single bucket bagging machine, dust collectors and belt conveyors. In general, you need to prepare $180,000-$220,000 budget for the granular organic fertilizer manufacturing system.

Learn more about the new type organic fertilizer granulation!

15 t/h powder organic fertilizer production line layout

When you comes to producing powdery organic fertilizer in 15 t/h, it only need 5 fertilizer machines. Wheel type compost turner, dynamic fertilizer feeder, SXFLF-1000 new type vertical grinder, double shaft mixer, SXGS-2080 rotary sieving equipment, double bucket powder packaging scales, belt conveyor. Generally, The quote of the powdery organic fertilizer making system is between $60,000-$100,000.

Learn more about the powder organic fertilizer making!

For another, you can choose to combine them into one composite organic fertilizer manufacturing plan. Here, you can replace organic fertilizer machine with the 20 t/h one. Such as 20 m wheel type composting equipment, dynamic batching machine with large hoppers, SXFLF-1000 vertical crusher (8-15 t/h) * 2, double shaft blender with to outlets, etc. Then, transport them to powder packaging machine and the organic fertilizer pelletizer separately. Because of area limited, the Zambian client finally choose the composite one.

Can the 5 t/h organic fertilizer granulation line use stirring teeth granulator?

For the organic fertilizer granule making, the client from Zambia wanted to buy a stirring teeth granulation machine. And asked about the possibility.

The answer is yes. Then the SXJZ-1200 new type organic fertilizer granulator (stirring teeth pelletizer) is the best choice. It can fully meet your requirements for produce 5 tons of organic manure granules in 3 mm size. In general, the less water the smaller size, the much water, the larger the size. In addition, the fertilizer granulation rate can reach 95% and granulated organic fertilizer has a high hardness.

| Model | SXJZ-1200 | Feed Moisture | 20%-40% |

| Capacity (T/H) | 4-6 | Feed Size (mesh) | 50 |

| Granulation Rate | 95% | Power (kw) | 90 |

| Granule Size (mm) | 2-5 | Dimensions (mm) | 4900x2550x1800 |

Inquiry the new type organic fertilizer granulator!

Can we add phosphate rock in the process of the organic fertilizer production?

Moreover, besides animal manure waste including cow dung, chicken poop and goat manure, the client also planned to add the phosphate rock in the organic fertilizer manufacturing. For this, there are 3 aspects you need to pay attention to.

Phosphate rock power preparing

To making organic fertilizer with phosphate rock, it is necessary to crushing the phosphate ore into powder. If your material is large size phosphate rocks, we recommend to buy a Raymond mill. Which can process phosphate rock into fine power quickly. But, when you plan to collect the powder material, you can feed it into fertilizer batching equipment directly.

Get the Phosphate rock processing machine!

Batching manure compost with phosphate rock

Then, you need to feed phosphate rock powder into manure compost according to the formula. For the establishing of the 20 T/H organic fertilizer plant costs $300,000, it is advisable to use a dynamic batching machine. Which has high precise of organic fertilizer making material batching quickly.

Mixing materials evenly

Besides, in order to ensure the organic fertilizer granulation with balanced nutrients, you need to mix phosphate rock powder with manure compost evenly. For 20 TPH capacity, we design 2 sets of double shaft horizontal mixers for the Zambian customer.

Then, dividing the mixture into two parts to transport to powder and granular organic fertilizer production lines respectively.

The above are details about our communication with the customer about how to setup a organic fertilizer plant costs $300,000 in Zambia. If you want to start the organic fertilizer making line, which similar to the project, welcome to contact us now! Moreover, there are also simple fertilizer composting plan, NPK fertilizer production system, etc in YUSHUNXIN waiting for you.