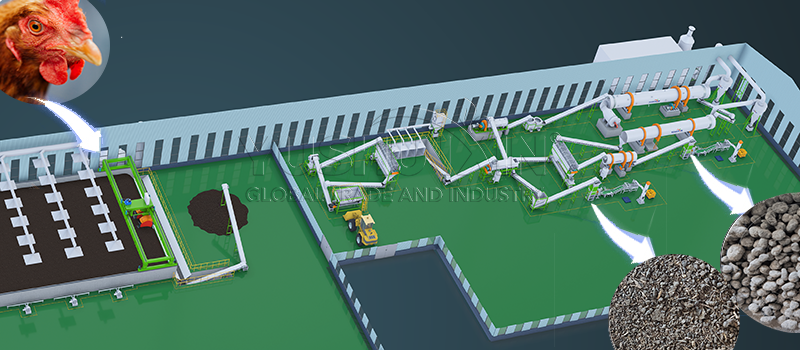

Poultry industry is one of the fastest growing markets. But as the poultry industry expanding its wings, it produces a large amount of manure waste. This will cause serious pollution of environment and disease threat of poultry farms, even endangering human health. Therefore, poultry manure management is important for farm owners. Then how to manage poultry waste? Making it into organic fertilizer is an ideal choice for them. But how to do it scientifically? For this, composting is necessary to kill harmful substance in poultry manure. Then, you can choose to turn poultry litter into powder or granular organic fertilizer. The former is an ideal choice for the limited budget, the latter can help you make more profits. But, whether the former or latter, YUSHUNXIN can provide you with the best solutions and machines.

Main Parameters

- Capacity: 1-20 t/h

- Products: Powder/granule organic fertilizer

- Design: compost turner, crusher, mixer, granule machine, screen, dryer, packing scale, etc

- Equipment material: Carbon steel Q235/Alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: Dispose of polutry waste, such as chicken poop, duck droppings, goose droppings, etc

How to design a suitable poultry manure fertilizer making plan?

Why so many farm owners choose to turn poultry waste into organic fertilizer?

From the above, it can be seen that poultry manure treatment is necessary. But why so many farm owners choose to turn poultry waste into organic fertilizer? Because poultry droppings have rich nutrient content. The percentages of nutrients contained in poultry manure to the intake are nitrogen (65.5%), potassium (83.5%) and phosphorus (68.5%). The three elements are beneficial for increasing crop production. And poultry manure also contains an appreciable amount of other nutrients. Such as calcium, magnesium, sulfur, boron, molybdenum, cobalt, copper, iron, manganese, zinc, etc. So utilization of poultry waste as a source of organic fertilizer production has been the favored choice for recycling nutrients.

Why composting is necessary for poultry manure treatment project?

No matter how you dispose of poultry manure, composting is necessary for using it as fertilizer. Because you must remove harmful substances from poultry droppings. Such as harmful bacteria, pest eggs, grass weeds, etc. During fertilizer composting, the temperature of poultry waste will keep at 65°-70°, which can kill them. And after fermentation, poultry manure will no longer smell bad and not affect human health.

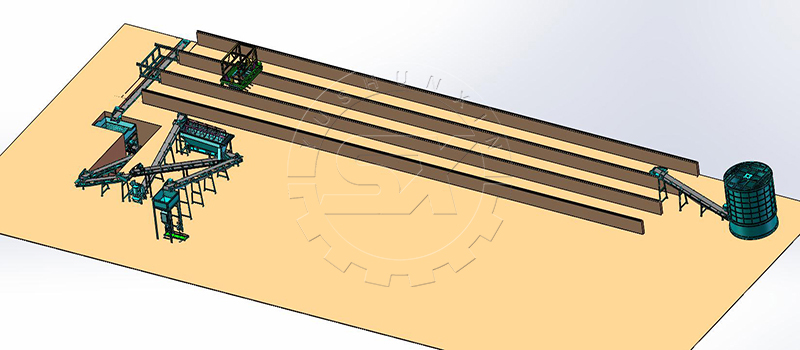

For poultry waste composting, we can offer you professional equipment to finish it easily. If you have a large scale composting, we recommend you choose our wheel type compost turner. If you don’t have enough budget, you can choose windrow compost turner. What’s more, we design organic fertilizer fermentation tank for those who don’t have enough space for composting.

How to compost and decompose poultry manure quickly ?

How to manage poultry waste in an economical way?

For those farmers who want to manage poultry waste at low cost, we especially design the powdery fertilizer production line. It is the simplest plan for disposing of poultry manure. Only four steps, you can make it into powdery organic fertilizer. Including feeding, crushing, screening and packaging. And it has a high degree of automation, and it only needs 2-3 works to operate. So you can spend less on equipment and labor force. If you have any special requirements, we can provide you with customization service. Therefore, the powder organic fertilizer production line is suitable for the poultry manure processing of small farms.

Top 2 granular fertilizer production methods for poultry litter treatment

If you want to further improve the utilization value of poultry manure. You can make poultry waste into granular fertilizer. After granulation, poultry waste fertilizer is not easy to cake and stick. It is convenient for transport and storage. So granular fertilizer has higher competitiveness in the market. In general, if you want to manage poultry waste by making it into granular fertilizer. There are two fertilizer granulation lines for your choice. Fertilizer wet granulation line and dry pelleting production line. You can choose according to your needs.

Wet granulation production line for poultry manure fertilizer pellet making

If you want to produce poultry waste fertilizer with higher strength and not easy to pulverize. Wet granulation production line is an ideal choice for you. Because during wet granulation, it usually uses liquid as binder to enhance adhesive force between poultry manure materials. So the finished fertilizer granules have lower possibility of powdering and less pollution during transportation.

In this case, we can provide you with pan granulation machine, new type organic fertilizer granulator and drum pelletizer. Among them, the first two are more suitable for small and medium poultry farms. If you need to process poultry compost of more than 150 tons a day, you can choose SXZGZ-2080 or SXZGZ-3210 rotary drum granulator. Their capacities are 8-15 t/h and 15-30 t/h respectively. They can fully meet your needs.

What is the cost of poultry manure granules making?

Dry granulation fertilizer making line for poultry waste management

But if the moisture content of the poultry waste is less than 10%, dry granulation fertilizer making line is more suitable for you. Here, we can provide you with flat die pelleting equipment. It mainly adopts extrusion granulation method and nearly doesn’t need water. So you reduce the cost of buying fertilizer dryer and cooler. In addition, in order to meet different needs for pellet size from poultry farm owners. We design a variety of molds for it. Configured with them, flat die pelletizer can produce fertilizer particles within 2-8 mm. And its capacity is 1-2.5 t/h, so it is an excellent option for small farms.

Top auxiliary equipment used in poultry manure disposal

Expect fertilizer compost equipment and granulator, there are many other fertilizer machines which are essential for poultry manure disposal. For example:

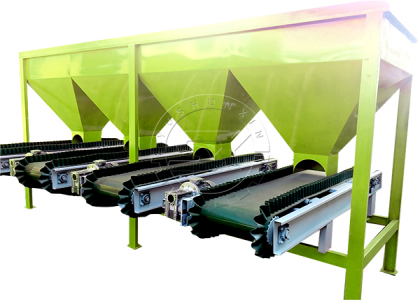

Batching machine

If you want to improve finish poultry manure fertilizer quality, batching machine can help you a lot. Through it, you can add some materials to enrich the nutrient content of poultry manure or add bentonite to enhance its adhesive force. These both contribute to better poultry waste treatment. Here, we can offer you static batching machine and dynamic automatic batching system for your choice.

Fertilizer screener for sale

When we make fertilizer out of poultry waste, we will find that not all fertilizers can meet your requirement after the first processing. You need to return them to reprocess. How to distinguish qualified fertilizer from the unqualified? Fertilizer screener can help you in this aspect, whether you process poultry manure into powder or granules. Powdery screening machine can divide fertilizer made of poultry waste into two parts. Fine powder and unqualified powder. And screener for fertilizer granules can divide them into three parts. Fine powder and small pellets, 3-5 mm particles, large granules.

Packaging machine

This is the final step of poultry waste management project. For this, we can provide you with automatic packaging scale. It can help you bag and seal poultry manure fertilizer easier and quicker. And the quantitative precision of the system is 2‰. Therefore, the weight error of fertilizer is smaller.

Belt conveyor

Expect the equipment mentioned above, what else do we need to manage poultry feces? Conveyor, which is used to transport poultry waste from one procedure to the next. The most popular conveyor with fertilizer manufacturers is belt conveyor. It can transport poultry manure stably and not easy to deform. Because its belt is made of high quality rubber and the density of the support rollers is higher. In addition, it is controlled by electronic equipment. You can adjust the speed and volume of materials transportation. So it plays an important role in your poultry waste management project.

What SX can provide you for better poultry waste manage?

SX is a professional fertilizer equipment factory, which has nearly 20 years experience in organic and compound fertilizer machine manufacturing. It can help you in many aspects of poultry waste management.

High quality equipment

All SX fertilizer equipment used in poultry manure treatment is made of high quality steel. And the area which is in contact with poultry waste will use anti-corrosion materials. So our fertilizer processing machine can meet the international criterion and operate for a long time.

Ideal price

SX is the source factory of fertilizer equipment. So there is no extra charge you need to pay. And we have mature technology for producing poultry waste processing equipment. Therefore, we can provide you with high quality equipment at an excellent price.

Reasonable project design

SX can design poultry manure fertilizer making project according to your actual conditions. Such as budget, workshop area, capacity, material, etc. This can make you treat poultry waste better.

Excellent after-sales service

After your machine is put into operation, if you need help with installation, usage or maintenance, you can contact us immediately. We will offer you solutions as soon as possible. And we will report your feedback to the R&D Department to optimize our products. Then applying the most advanced technology into fertilizer equipment production to provide better products for you.

Lastest successful cases of poultry manure ferilizer making for your reference!

In addition, we have helped many poultry farm owners setup organic fertilizer making line for poultry manure disposal. Not only solid poultry manure fertilizer making line in Malawi but also poultry manure to liquid fertilizer manufacturing project in Australia.

At the same time, YUSHUNXIN can offer you many other fertilizer making plans. Such as cow dung fertilizer business plan, pig manure disposal system, NPK fertilizer manufacturing project design, etc. Welcome to contact us to get your own fertilizer making lines and machines now!