Besides making solid fertilizer from cow manure, you also can choose to dispose cow dung waste into liquid fertilizer. For this, we can offer you customized cow manure liquid fertilizer production plan and machines. They can fully meet your requirements to make liquid fertilizer from cow dung in wet, dry or after biogas production, etc.

Get the liquid cow manure fertilizer making line now!

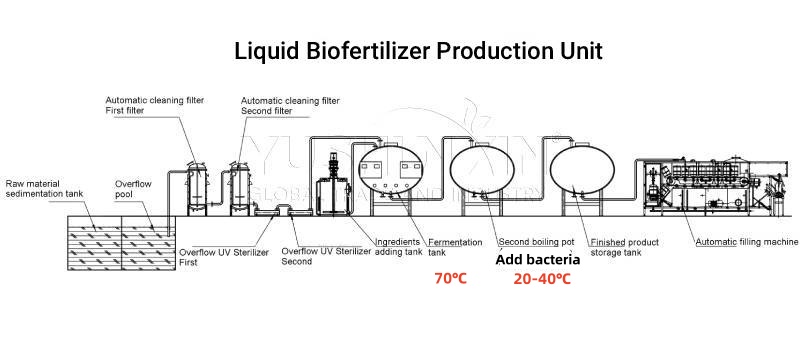

6 Steps to make liquid fertilizer from cow dung

In general, to dispose of cow dung into quality liquid organic fertilizer, it needs 6 steps.

Collect Fresh Cow Dung for liquid fertilizer making

Usually, quality liquid water-soluble fertilizer manufacturing starts by collecting fresh cow dung. It’s advisable to use fresh cattle manure material. Because it contains a higher concentration of nutrients and beneficial microorganisms compared to older, dried dung. At the same time, you can get the liquid fertilizer material directly.

Filter liquid cow dung for fertilizer production

It contains 2 parts. For one thing, removing solid cow manure from the liquid. Here, you can use a manure solid and liquid separator. Or you can setup a sedimentation trench for separater liquid cow manure material economically. For another, filtering small particles from liquid cow manure material. So, you can produce water soluble fertilizer which is easier to use. Here, our engineer adopts activated carbon filtering design.

UV liquid fertilizer Sterilization

Then in order to eliminate harmful pathogens, viruses, fungi, etc to ensure the safety of produced liquid fertilizers. As the name suggests, our system to make liquid fertilizer from cow dung adopts UV sterilization technology. Its pathogens elimination rate can reach 99%.

Auxiliary material adding

If you want to add some NPK, trace elements to improve nutrient content or molasses or fermentation agent to speed up the liquid fertilizer fermentation, there is batching tank for you. Mixing additives with water, the batching tank will send then to liquid cow manure fermentor according to required proportions.

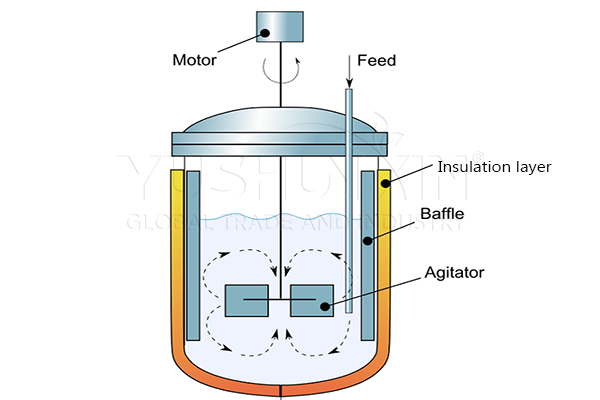

Liquid cow manure fertilizer mixing and fermentation

For producing liquid fertilizer from cow dung, fermentation is important. Similar with solid cow manure fertilizer production, it is a harmless process of liquid fertilizer. With stainless steel liquid fertilizer reactor mixing, enzymatic hydrolysis will take place to decompose nutrient substances into smaller molecules and further eliminate harmful pathogens in materials.

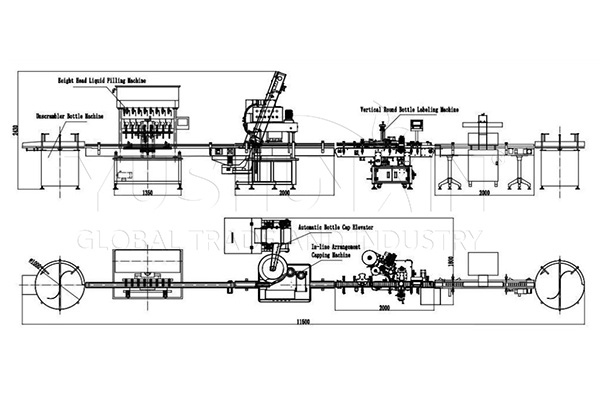

Cow manure liquid fertilizer packing

Finally, for commercial liquid fertilizer production, you need to packing finished cow manure fertilizer. For this, automatic liquid filling machine is the best choice. It can finish liquid fertilizer filling, covering, labeling, etc.

Get your customized cow manure liquid fertilizer making line!

How long does it take for liquid cow manure fermentation?

Commonly, the time for cow manure liquid fertilizer fermentation is depended on method employment.

- For makes use of enzymes to decompose cow manure slurry liquid, the anaerobic fermentation, it needs only 3-7 days.

- As for aerobic fermentation with bacterial hydrolysis, it usually take you 15-25 days.

Therefore, we usually recommend you choose to buy anaerobic fermentation tank for making liquid fertilizer from cow manure.

How many chelating agents need to add during liquid fermentation?

In order to make liquid fertilizer from cow dung quickly, you can also choose to add chelating agents to speed up the liquid reaction. It mainly utilizes its chelation with metal ions to form soluble chelates. Which can increase the concentration of inorganic nutrients in liquid fertilizers, and prevent crystallization and precipitation. As for the amount of chelating agent adding, it is generally less than 5% of the mass of the raw material.

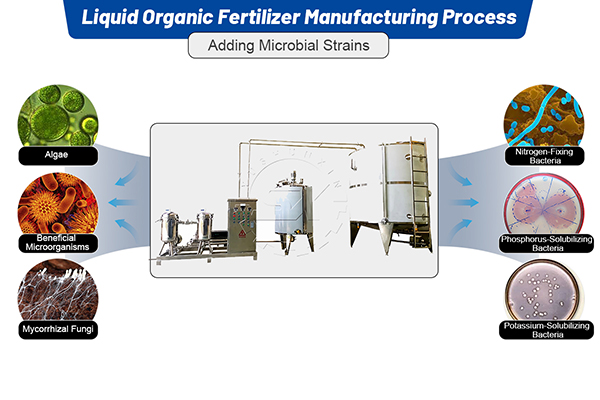

How to produce bio liquid fertilizer with cow manure?

If you want to prepare cow manure into liquid biofertilizer, the above fertilizer making line also can fully meet your requirements. You only need to add secondary chelation system and ultrafiltration membrane components after the liquid cow manure fertilizer reactor.

- The former is to key to ensure microorganism survival in liquid cow dung biofertilizer manufacturing. This will control the temperature of functional bacteria adding and dissolving to 20-40℃, which prevent from high temperature damage.

- The latter is to remove tiny particles, fungal spores, and insoluble residues from the secondary chelation liquid bio fertilizer. With 0.1 μ m-0.2μ m filtering precision, you can produce better liquid fertilizer and reduce the clogging in subsequent liquid filling process.

Get your customized cow manure liquid fertilizer making line!

Can we make dry cow manure into liquid fertilizer?

Of course. To processing dry cow manure into liquid fertilizer, it is advisable to add water before liquid fertilizer fermentation.

Here, YUSHUXIN can provide you with reverse osmosis equipment, which can offer high-purity water for cow manure liquid fertilizer manufacturing. It can purify municipal tap water, non polluting groundwater or surface water and lake water. Generally, the ideal dry cow dung liquid fertilizer production process is cow dung crusher→ reverse osmosis equipment (water adding)→baching tank→ liquid reactor → solid filters → liquid filling equipment

Is there operational fertilizer plant for making liquid fertilizer from cow dung?

Of course. Many manufacturers start their cow dung liquid fertilizer business with YUSHUNXIN equipment. For example, on 5th January 2025, a customer from Ethiopia inquired about how to dispose of cow manure waste into fertilizer? Considering local market demand and ROI, he finally choose to buy a liquid fertilizer making system for Ethiopia cow dung disposal. 1000 L/day. Now he told us the system works good and start sell produced liquid fertilizer to the customers.

Project Overview

- Country: Ethiopia

- Capacity: 1 t/h

- Material: cow dung

- Rquirement: Liquid fertilizer making

- Cost: $75,640 USD

If you have any other questions for how to make liquid fertilizer from cow dung, welcome to contact us immediately. Of course, YUSHUNXIN also can offer you other liquid fertilizer making lines. Such as system to make chicken manure liquid fertilizer, pig manure, biogas waste, etc.