The agriculture in the United States has characteristics of single crop and manpower insufficiency. Therefore, it is difficult for organic or natural inorganic fertilizers to return to the cultivated land. Such as human waste, animal manure, and plant ash. So compound fertilizer production plays an important role in the US. In August 2022, a customer from the USA inquired about how to make granular compound fertilizer from powder? Then after negotiation on details, we recommend him suitable equipment for granular compound fertilizer making. The following are the specific details of the communication in this case:

Project Overview

- Location: United States

- Capacity: 3-4 T/H

- Material: activated carbon, calcium sulfite and some mineral materials

- Rquirement: Compound fertilizer pellet making

- Cost: $138,320

- Solution: Double roller granulation line

What is the best way to make granular compound fertlizer from activated carbon, calcium sulfiteand mineral materials?

This customer from the United States planned to use activated carbon, calcium sulfite and other minerals to make granular compound fertilizer. As for capacity, 3-4 T/H complex fertilizer pellets production is the best. Additionally, the mateials for compound fertilizer making has a moisture of lower than 10%.

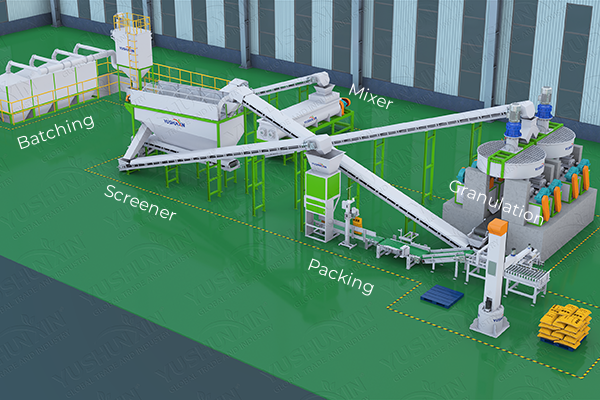

For this, we recommend to buy a fertilizer dry granulation line with 2 sets of SXDG-2T roller press granulators. With the machine, you can turn activated carbon, calcium sulfite and mineral powder into complex fertilizer granules without liquid binder. So, you can reduce the cost of fertilizer dryer and cooler purchasing. Namely, the 3-4 T/H compound fertilizer pellet making line needs only 6 machines. They are batching machine, double shaft mixer, SXDG-2T double roller granulator, SXGS-1240 rotary screener of pellets and single bucket packing machine. At the same time, the complex fertilizer granulating rate can reach 97%.

| Model | Capacity (T/H) | Power (kw) | Granule Size (mm) | Dimensions (mm) |

|---|---|---|---|---|

| SXDG-2T | 2 | 22 | 3-10 | 1630X850x1650 |

Inquiry more about the compound fertilizer granulator!

Can we produce 3 mm compound fertilizer pellets with the double roller granulation line?

In terms of compound fertilizer particle size, the American customer required a diameter of 3 mm. He wanted to know can the roller granulation line finish it?

Of course. YUSHUNXIN double roller granulation line for compound fertilizer making can fully meet your needs. In general, you can change complex fertilizer granules size by only one ways when you adopts roller extrusion granulation equipment. It is equip the powder granulation machine with roller sheet of desired size ball sockets. For example, if you plan to prepare compound fertilizer pellets with 3 mm diameter, you need to choose roller sheets with 3 mm ball sockets.

Get more videos about double roller granulator!

How much does the system to make granular compound fertlizer cost?

As mentioned above, thre is no dryer and coller in the roller press compound fertilizer making line. So, compared with other complex fertilizer pellets manufacturing system, it has a lower cost. Such as the 3-4 T/H roller dry granulation line costs about $145,600. Then because the compound fertilizer manufacturer paid a deposit of 50%, there is a 5% discourt. Finally, the compound fertilizer making line costs only $138,320.

The above are details about our communication with the customer from the United States. Expect granulator, our company also can provide you with many other compound fertilizer granulation plans. Such as commercial disc granulation line and large scale drum granulation system, BB fertilizer production line, etc.