On 18th June 2024, a customer from Bolivia inquired about how to make compound fertilizer granules? “The reason I am writing to you is to ask you to give me a quote for the equipment for the production of compound fertilizer granules for a capacity of 5 t/h and the raw materials are monocalcium phosphate and potassium chloride and finally kaolin. They have a humidity of approximately 0.2% and particle size of 0.3 mm. The granules must have a particle size between 2 to 4 mm and the addition of a dye is also required so that it has a red appearance.” The following are the specific details of this case.

Main Paramters

- Country: Bolivia

- Capacity: 5 t/h

- Material: monocalcium phosphate, potassium chloride and kaolin

- Material Moisture: 0.2%

- Requirement: 2-4 mm red granule making

- Solution: Double roller granulation machine, dynamic batching machine, granule screener, coating equipment and packing machine, etc.

How to make compound fertilizer granules with 5 TPH output in Bolivia quickly?

Because the Bolivia clients planed to produce compound fertilizer pellets from monocalcium phosphate, potassium chloride and kaolin and the 0.2% humidity, we recommend you to buy double roller granulator line. It is the best cost-effective choice for a dry powder granulation project.

For one thing, it can granulate 0.2% humidity chemical powder into granules without drying. This is beneficial for start an economical compound fertilizer making plant.

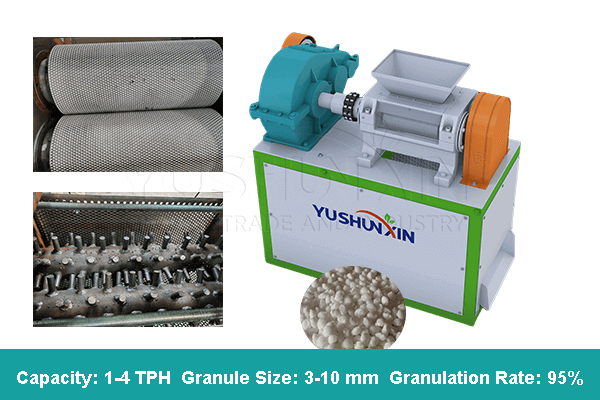

For another, for 5 t/h compound fertilizer granulation, it only needs two 3 t/h double roller granulators. Which only pricing $17,566 in YUSHUNXIN fertilizer machine factory.

Can double roller granulator process 0.3 mm chemical powder into pellets?

In addition, the Bolivia compound fertilizer manufacturer worried about is 0.3 mm size material suitable for the machine? The answer is yes. Generally, The feeding material size for double roller press granulator is 50-200 mesh, namely 0.127-0.508 mm. This is to ensure that rollers can press chemical powder into granular complex fertilizer quickly and easily.

Tip: If your material for compound fertilizer granule manufacturing has a over 0.6 mm size, it is advisable to buy a fertilizer crusher. You can add the machine before double roller extrusion machine.

How to produce compound fertilizer granules into 2 to 4 mm size?

Then, the client told us the wishes of making compound fertilizer pellets with 2 to 4 mm size. And asked that how to regulate the chemical fertilizer granule size when use a roller press granulation equipment?

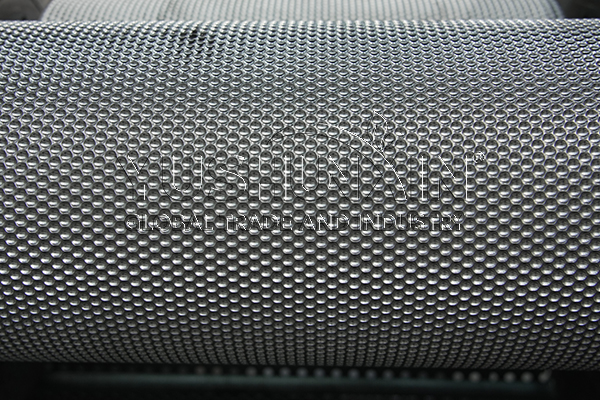

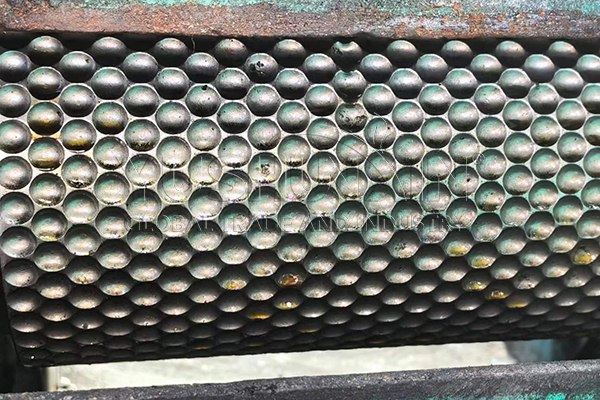

For this, it is depended on the size of ball sockets on roller sheets. Because the double roller granulator mainly relies on the extrusion force to turn powdery compound fertilizer into granular shape. As a reliable fertilizer equipment manufacturer, we can provide you with roller sheets for 3-10 mm chemical fertilizer granulation. Of course, including roller sheets with 2 mm and 4 mm ball sockets.

Can we prepare red appearance compound fertilizer pellets?

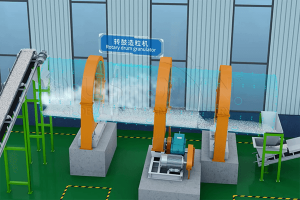

If you want to add dye in compound fertilizer granule making to add a red color appearance, buy a coating machine is the best solution. The machine has a a spray device to add red dye to granulated compound fertilizer. Then, under the action of fertilizer coating machine rotation, the red dye will coat your fertilizer granules evenly.

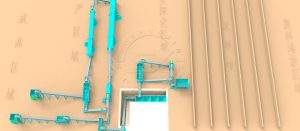

Finally, the whole 5 TPH business plan to make compound fertilizer granules consists of 5 machines. Including dynamic batching machine → double shaft mixer → double roller granulators *2 → screening machine → coating equipment → granule fertilizer packing scale.

The above are details about our communication with the customer about how to make compound fertilizer granules with 5 TPH output in Bolivia. In addition, YUSHUNXIN can also provide you with fertilizer machines for other compound fertilizer making lines. Such as NPK fertilizer production, phosphate fertilizer production, etc. Welcome to get your own fertilizer making equipment immediately.