If you want to further improve the quality of cow manure fertilizer making, you can add microbial agent to produce bio fertilizer. For this, YUSHUNXIN can provide you with professional fertilizer equipment and solutions to make bio fertilizer from cow dung waste. Of course. It contains powdery or granular cow manure bio fertilizer. Whether you need equipment for small, medium or large scale bio fertilizer preparation. We can fully meet your needs.

Main Parameters

- Capacity: 1-20 t/h

- Types: powder & granule

- Equipment: Compost turner, crusher, mixer, granulator, dryer, cooler, coating machine, packing scale, etc. (Customized)

- Equipment material: Q235 Carbon steel or stainless steel

- Application: cow manure waste management, bio fertilizer production

Top 2 processes of making bio fertilizer from cow manure (cara membuat biofertilizer)

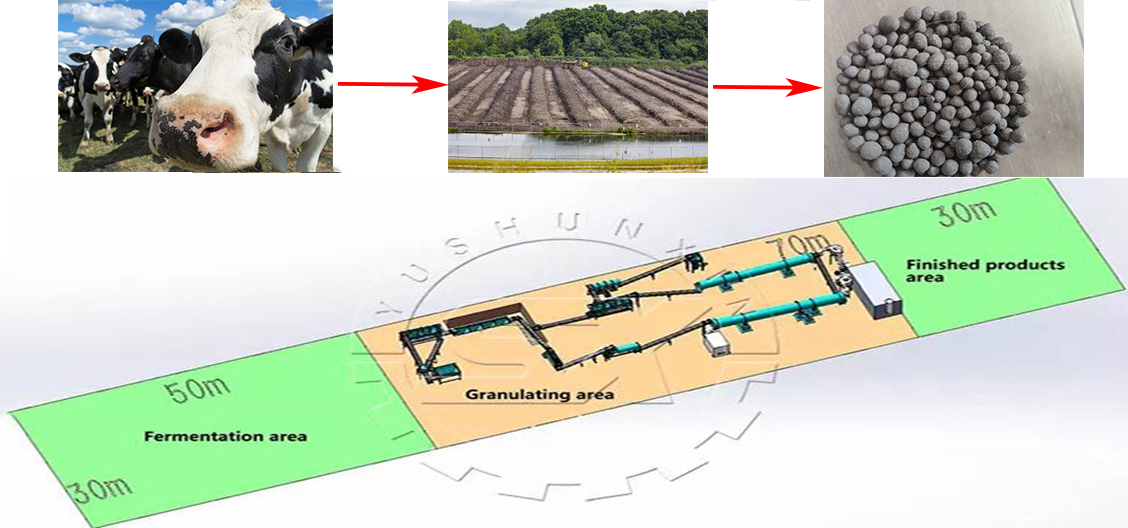

Converting cow manure to bio fertilizer is a win-win choice for you. On the one hand, you can dispose of the cow manure waste in your farms. On the other hand, making cow manure into bio fertilizer can increase your income. Then how to process cattle litter into bio fertilizer? In general, there are 2 types of bio fertilizer manufacturing processes for your choice. You can choose to make cattle waste into powdery and granular biofertilizer freely.

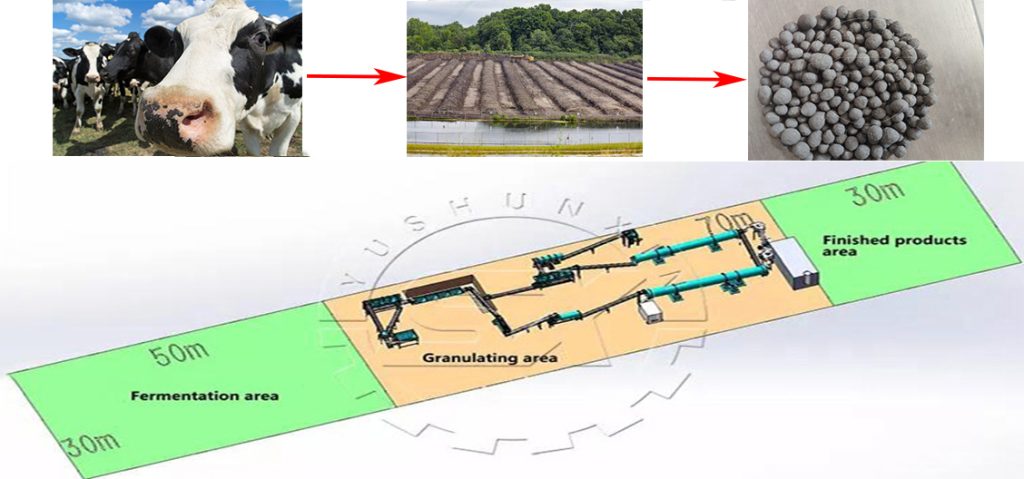

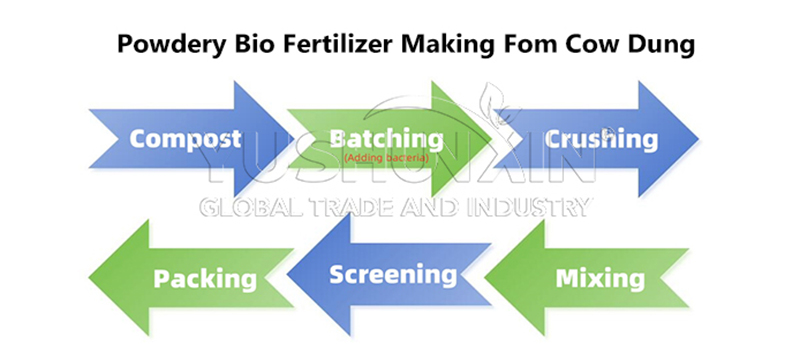

Economical powdery bio fertilizer production line

If you turn cow dung into bio fertilizer in a simple process and at a low cost, we recommend you powdery fertilizer making line. Because it consists of only compost machine, forklift feeder, crusher, mixer, screening equipment, conveyor belt and packing machine. Fewer fertilizer processing machines usually mean lower price and less space occupation. Its price is about $ 35,000- 90,000 and the area is 800-5000 ㎡. In addition, it has a high degree of automation, which can reduce cost on the labor force. Only 2-3 workers, you can operate the whole powdery production line to make cow dung into bio fertilizer. So you can greatly reduce the cost of bio fertilizer manufacturing.

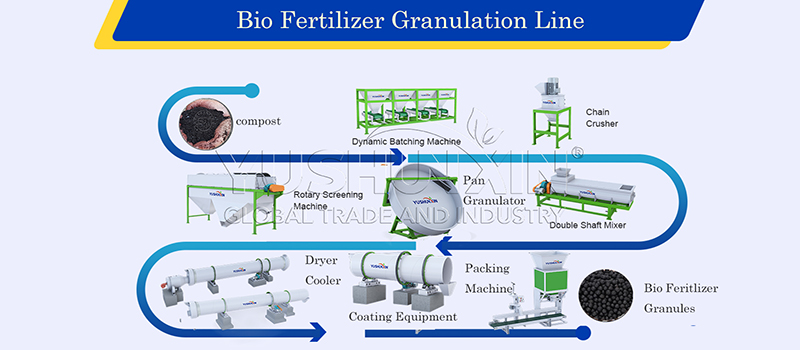

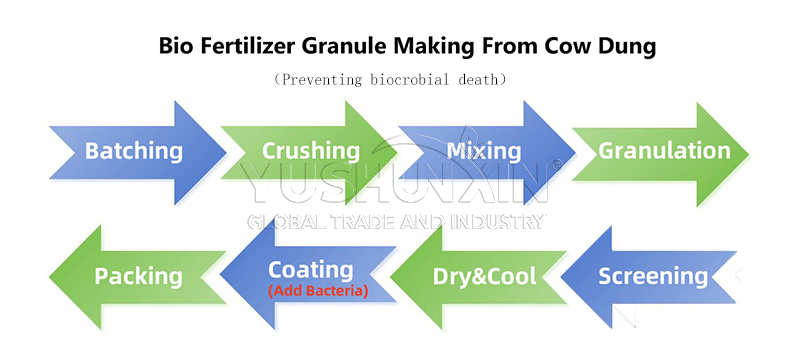

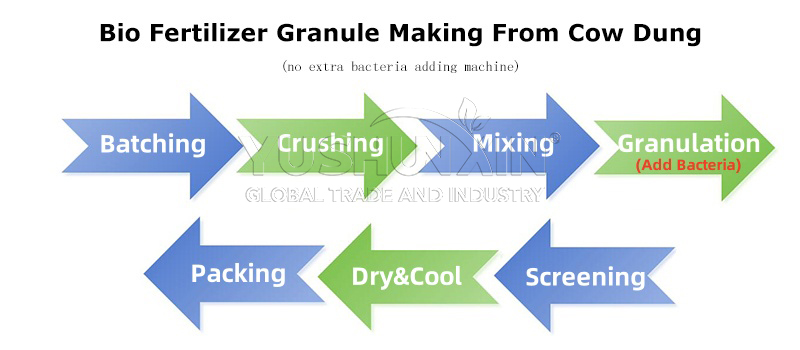

Quality bio fertilizer granule making system

But if you want to improve the competitiveness of your bio fertilizer made of cow manure. We can provide you with fertilizer pellet preparation line to make powder cow dung compost into bio fertilizer pellets. On the basis of the powdery bio fertilizer production line, it makes further processing for cow dung materials. For example, granulating cow manure into fertilizer particles to prevent pulverization and layering. Then drying and cooling it to further remove water from cow dung bio fertilizer pellets. And making it better for long time storage. After those processes, your bio fertilizer made of cattle manure will has a higher quality.

How to produce bio fertilizer with cow dung step by step?

Turning cow dung into powdery bio fertilizer

Further making powdery cow manure bio fertilizer into granules

If you want to further make powdery bio fertilizer into pellets, you also need to process it as follows:

- Granulation: It plays an important role in granular bio fertilizer making. After granulation, cow manure fertilizer is not easy to stick and pulverize. And you also can choose to add functional bacteria during this process.

- Drying and cooling: Further removing the moisture of cow dung bio fertilizer and making it meet the international requirement.

- Screening: Separating unqualified bio fertilizer pellets from the qualified, and return them to form into biofertilizer granule again.

- Coating: Coating a protective film on bio fertilizer to prevent water re-absorption and nutrients loss. And you also can choose to add functional bacteria here.

Methods of cow dung compost for bio fertilizer manufacturing

Cow dung composting is the basis of high quality bio fertilizer manufacturing. Therefore, you need to choose the right method to compost cow dung according to your actual conditions. In general, there are 3 compost methods for your choice to ferment cow dung for bio fertilizer production.

Static aerated composting

If you want to process cattle manure into bio fertilizer at a low cost, you can choose static aerated fermentation method (like membrane cover composting technology). Because it doesn’t need to use fertilizer compost turner. As long as making the cow dung material into piles of different shapes, and using the ventilation pipes to ventilate artificially. You can kill the pathogenic microorganisms, parasite eggs and grass seeds in cow litter.

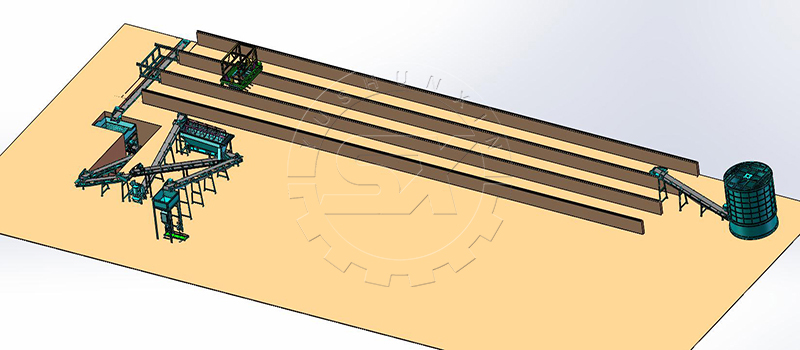

Windrow strips compost Making

If you want to make cow dung in fully fermentation faster, windrow strips composting is suitable for you. During this process, you need to make cow dung into windrows, whose sections are trapezoidal or triangular. And then using fertilizer compost turner to turn them to speed up compost. For compost turner, there are two choices for you. For one thing, you can directly pave them directly on concrete or asphalt ground. And then turning them with windrow compost turner. Here, SX can provide you with crawler type compost turner and moving type compost turning machine. For another, you can build some grooves to make cow dung bio fertilizer fermentation. For this, we will recommend you wheel type compost turner or groove type compost turning machine.

In-vessel compost Method

Is there compost method suitable for bio fertilizer making in a small space? Of course, in-vessel fermentation can fully meet your requirement. For this, our organic fertilizer fermentation tank is designed for you. Only 10-30 ㎡, it can finish the whole process of cow dung compost. It usually makes composting in a closed environment. And you can make cow dung compost by controlling ventilation, temperature and moisture. In addition, the in-vessel compostor can realize fully automatic working. So you can process cow dung into compost easily.

How to select suitable granulator for powdery cow dung bio fertilizer granulation?

Granulation is another essential step in the process of making cow dung into bio fertilizer. In order to meet different requirements from customers. SX especially design various granule making machines for different scale bio fertilizer production.

Small scale bio fertilizer making

If you plan to produce 1-6 tons of bio fertilizer per hour from cow droppings. All fertilizer granulating machines can meet your needs. But the most popular two are pan granulator and flat die pellet equipment. If you don’t have enough budget, pan granulator is your best choice. It also has features of less space occupation, high granulation rate, adjustable moisture, etc. But when you need to process cow dung with water content of below 10%, flat die pelletizer is an ideal option for you. Besides these two bio fertilizer pellet machines, we also can provide you with new type organic fertilizer pelletizer and rotary drum granulator.

Medium scale bio fertilizer manufacturing

When you need a cow dung bio fertilizer pellet making equipment with a capacity of 6-8t/h. We will recommend to you the new type granulator and rotary drum pelletizer. For those who need a pellet making equipment with less space occupation and low cost. It is advisable to buy the former. But if you require more energy- saving equipment, rotary drum pelletizer is more suitable for you to make bio fertilizer out of cattle waste.

Large scale bio fertilizer preparation

For large scale bio fertilizer plant, rotary drum pelletizer is the best choice. It has two types, SXZGZ-2080 and SXZGZ-3210, are especially designed for producing bio fertilizer from cow dung in a large scale. Their capacities are 8-15t/h and 15-30t/h respectively. In addition, in order to resist the corrosion of large amount of cow dung processing, we particularly add a rubber lining to it.

When to add microbial in biofertilizer production with cow dung?

It is no doubt that the addition of functional bacteria is important when you turn cow dung into bio fertilizer. However, which step is suitable for cow manure microbial microbial fertilizer making to add bacteria? You can choose to according to your needs.

In making powder biofertilizer with cow manure – before crushing

For preparing bio fertilizer powder from cow waste, it is advisable to add bacteria agent before crushing. And the powdery microbial agent is the best choice. In addition, to ensure the nutrient balance of final powdery cow dung biofertilizer production, you can use a powder mixer after crusher. The machine can mix the cow manure compost and bacteria agent evenly.

For cow dung bio fertilizer granule manufacturing

As for bio fertilizer pellet making from cow manure, there are 3 steps you can add the bacteria agent.

Preventing biocrobial death to the greatest extent – after drying

For those who want to prevent biocrobial death to the greatest extent in bio fertilizer manufacturing, our engineers recommend you choose to add it after drying and cooling. Because, the granule drying temperature can reach 60℃, which will damage the functional bacteria. For this, we can offer you coating machine, which has professional spray device to make powdery or liquid microbial agent form a film on the cow manure biofertilizer granule.

No extra bacteria adding fertilizer machine – during granulation

But, if you don’t want to add extra equipment, you can choose to add functional bacteria in cow compost to granule step. Here are disc granulation machine and drum granule machine designed for you. They also can be equipped with bacteria agent spray design easily. So you can control the microbial adding volume precisely and it requires no other bio fertilizer equipment.

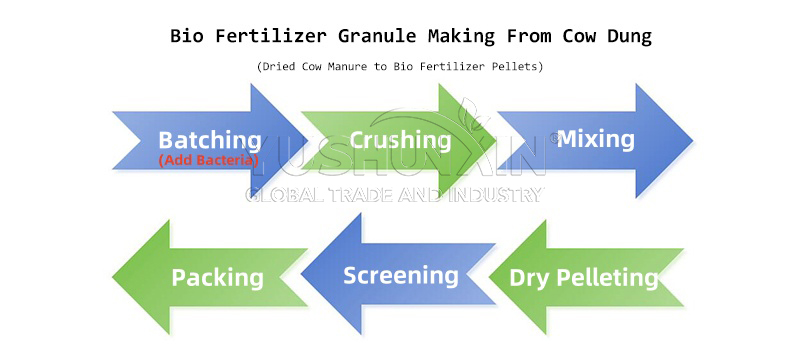

During dried cow dung compost to bio fertilizer pellet process – before crushing

Then how about the dried cow manure biofertilizer granule making? It uses dry double roller granulation machine, which cannot add spray device. It is same as powder biofertilizer making from cow dung, add bacterial agent before crushing. Then, making use of the mixer to blend them evenly.

What you need to focus on when adding functional bacteria for bio fertilizer production?

Moreover, in order to make quality bio fertilizer from cow dung, you also need to pay attention the microbial adding conditions. Generally speaking, you need to focus on 4 aspects as following:

Temperature

Temperature is an essential factor for microorganism growth. Usually functional bacteria don’t have high resistance to high temperature. And the optimal living temperature of it is 20-40 ℃.When the temperature is higher than 60℃, most functional bacteria will decease. So, it is better to add microbial agent after drying when making bio fertilizer for cow manure with wet granulation method.

Moisture content

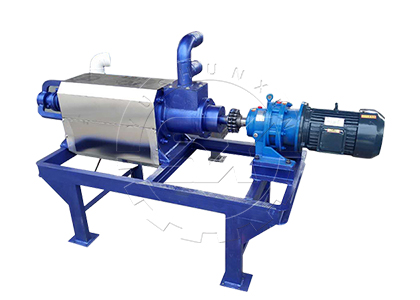

Moisture control throughout the whole process of making cow dung bio fertilizer. The same as functional bacteria addition. When the water content of cow dung is below 30%, the activity of functional bacteria will be reduced. And for cow dung bio fertilizer granulation, it cannot be higher than 45%. Then, how to dry cow manure quickly here? You can use dewatering machine. The machine can reduce the moisture to 30% fast.

Organic matters content (C/N)

During the bio fertilizer manufacturing, the content of organic matter and C/N are important factors affecting fertilizer efficiency. It is better to keep organic matter content at more than 30% and C/N at 30-35:1 initially and 15-20:1 after composting. Generally the C/N of cow dung is 8-26:1. You can increase it by mixing it with high C/N materials. Such as straw, peat, rice husk, etc. They are also excellent materials to increase organic matters. For convenience, you can grind them into powder with crusher.

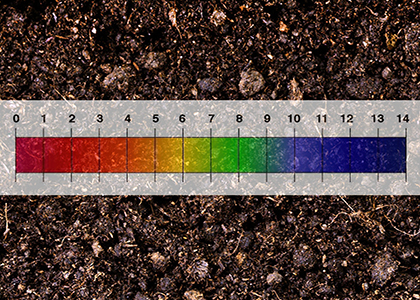

PH value

The PH value is also an item you need to focus on when adding functional bacteria for processing cow manure into bio fertilizer. Different bacteria have different requirements for PH value and it is also different in each period. When you need to enhance PH value, you can add lime and grass ash to cow dung. But if you want to decrease it, fresh green fertilizer and grass can help you.

If you have any other requirments for solutions and machines of biofertilizer making from cow manure, welcome to contact us at any time! There are also many other cow dung fertilizer making lines, such as liquid fertilizer production from cow manure, biochar fertilizer manufacturing with cow dung, etc.