Are you worried about how to dispose of animal waste in the farm? Do you need a project design which can make fertilizer at a low cost? SX fertilizer disc granulation line can fully meet your needs. It can help you produce high quality fertilizer granules, whether you want to prepare organic fertilizer, bio fertilizer or compound fertilizer. In addition, it mainly adopts wet granulation method, which can make finished fertilizer more convenient for transport and storage. And the capacity of this disc granulation production line is about 1-6 t/h. Therefore, if you plan to start a small or medium fertilizer plant, it is an ideal choice for you.

Main Parameters

- Capacity: 1-20 T/H

- Granulation Rate: over 93%

- Granule Size: 1-8 mm

- Granulation Method: Wet Granulation

- Cost: $80,000-$400,000

- Application: Organic fertilizer making, NPK fertilizer production, rock phosphate fertilizer manufacturing, etc.

What raw material is suitable for pan granulation line?

When you want to select a suitable fertilizer making line for your fertilizer plant, you need to consider whether this fertilizer production line can be used to process the material you have. But whether you want to produce organic fertilizer, compound fertilizer or bio fertilizer. SX disc pelleting line is an excellent choice for you. And there are some materials for your reference to use in pan granulation line:

Materials for organic fertilizer or bio fertilizer making

If you want to use pan pelleting line to produce organic or bio fertilizer, we recommend you choose following materials:

Materials for compound fertilizer manufacturing

Compound fertilizer mainly consists of three types of elements, nitrogen, phosphorus and potassium. Therefore, if you plan to manufacture compound fertilizer, you can choose materials as follows:

What method is used in the pan granulation production line?

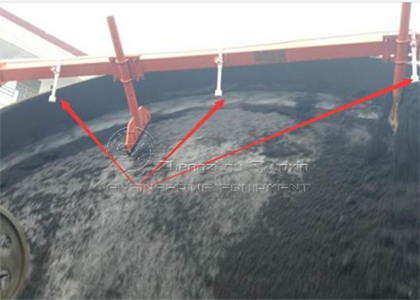

The fertilizer pan granulation line mainly adopts wet granulation method. It usually uses liquid as binder to increase the adhesive force between fertilizer powdery. So the final fertilizer pellets have a higher density and are not easy to pulverize. This kind of fertilizer is easier to transport and store. Then how to add liquid in the process of disc granulation line operation? We especially design a spraying device above the pan pelleting machine. After the powdery material is transported in the disc pelletizer and the disc starts rotating. You can control the amount of liquid added by the spraying device. It can greatly contribute to improving the quality of your fertilizer particles.

2 popular disc granulation making line in SX fertilizer equipment factory

From the above, we can know that the pan granulation production line can be used in organic and compound fertilizer making. Is there any difference between them? There are some details about them for your reference.

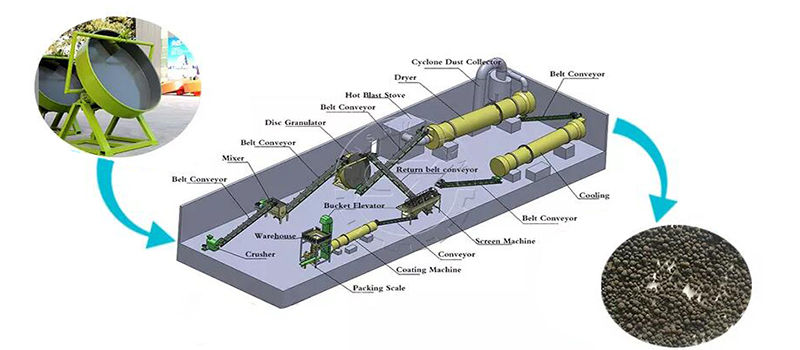

Disc pelleting line for compound fertilizer manufacturing

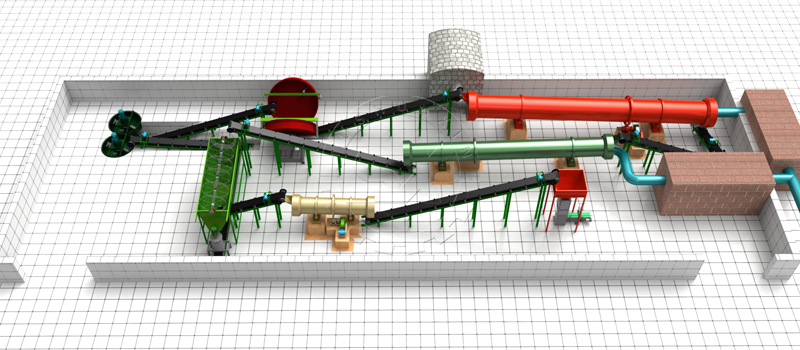

When you want to buy the disc granulation line for your compound fertilizer production plant, it is essential to know what equipment is needed in it.

In the beginning, it needs an automatic batching machine to ensure that the proportion of raw materials is consistent with the formula. Then fertilizer mixer will help you mingle them evenly to prevent nutrients imbalance. Next, pan granulator will turn powdery chemical materials into particles. Then granular fertilizer screener can help you separate required pellets from the unqualified. And because wet granulation method usually involve liquid in fertilizer making process. It is advisable to use dryer and cooler to further remove excessive moisture of compound fertilizer granules. Finally, you need an automatic packaging machine to bag finished complex fertilizer. SX can provide you with all equipment for this compound fertilizer pan granulation line. It has high quality and strong adaptability. So you can use it to make NPK fertilizer, urea complex fertilizer, nitrogen compound fertilizer, etc

Pan granulation line for organic fertilizer making

The process of organic fertilizer pan granulation production line is more intricate than the above compound fertilizer making line. So besides the above fertilizer machines, there also are three fertilizer processing machines you may need.

As mentioned above, the preparation of organic fertilizer mainly uses animal manure as material, which contains a large amount of harmful bacteria and pest eggs. Here fertilizer composting machines can help you a lot. It can turn and stir the manure to facilitate the compost process to kill bad substances in it. And for this, we have trench type compost turner, windrow composter and in-vessel fermentation tank for your choice. After composting, you will find that the material has a phenomenon of sticking and agglomeration. This will reduce the effect of granulation. Therefore, we equip this organic fertilizer line with a fertilizer crusher to grind material into fine powder. Then you can transport it to the batching machine and continue to process it. But if you use fresh animal manure to make organic fertilizer, excessive moisture will reduce the quality of final fertilizer. SX can provide you with dewatering machine to reduce the water content of manure.

How to change the size of fertilizer granule produced in disc granulation making line?

During granular fertilizer making, there is an item many fertilizer manufacturers focus on. It is how to produce fertilizer pellet of the required size? Or how to change fertilizer granule size? If you choose to make organic or compound fertilizer by pan granulation line, our engineers have two advice for you.

Control moisture content

Water content plays an important role in fertilizer pellet size regulation. Generally speaking, less water, smaller size; much water, bigger size. And in order to make it easier to control the moisture content of fertilizer material, we especially design spraying device above the pan granulating machine.

Adjust pelletizer disc angle

For fertilizer pan granulation line, there is also another method to change your fertilizer particle size. You can finish it by adjusting the disc angle between 35 degrees and 55 degrees. Sharp slope, smaller size; slow slope, bigger size. Doing this, you can produce fertilizer granule with a diameter you need within 1-8 mm.

How much does disc pan granulation system cost?

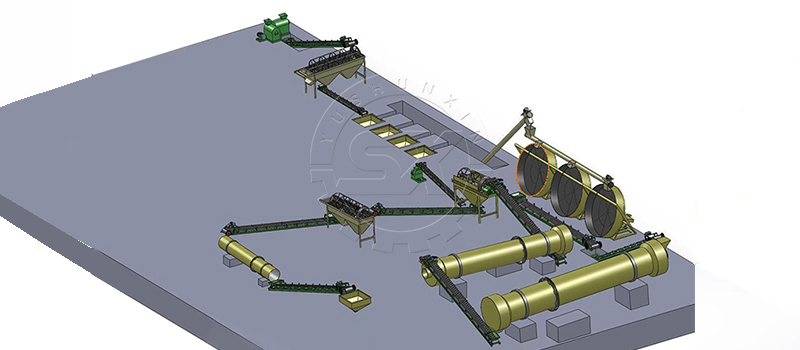

How to design pan granulation line for your fertilizer plant?

If you want to make high quality fertilizer efficiently, besides suitable fertilizer manufacturing line, reasonable project design is also an aspect you need to pay attention to. SX can provide you with optimum fertilizer plant layout design out of charge. We will design it according to your actual conditions. It usually contains workshop area, budget, capacity, material, etc.

For example, if you plan to start a small scale fertilizer plant, we recommend you choose disc pelleting machine SXYZ-1800, SXYZ-2000 and SXYZ-2500. If you want to enlarge your fertilizer production scale, it is advisable to use pan granulator SXYZ-2800, SXYZ-3000 and SXYZ-3600. And if your workshop area is not enough it is an ideal choice to change belt conveyor to bucket elevator and choose fermentation tank for organic fertilizer composting. If you also have any special requirements for pan granulation production line, you can contact us for customization.

How much does a complete fertilizer disc pelleting line cost?

The price of pan granulation line must be an item many fertilizer manufacturers focus on. But it is not a fixed number. It will vary with configuration, material cost, market conditions, etc. In general, for 1-20 TPH capacity, the price of complete compound fertilizer pan granulation line is about $80,000-$350,000. And organic fertilizer disc granulation line will cost $100,000-$400,000. If you want to know the latest price of fertilizer pan granulation line, please contact us immediately.

Besides, there are rotary drum granulation line for easier large scale fertilizer granulation line, roller granulation plan for low cost dry powder pellet making, etc. Come to contact us to start your fertilizer making business now!