Drum coating machine is widely used after granular fertilizer cooling and before fertilizer packaging. With fertilizer producers and buyers becoming more discerning, demand for high-quality granular fertilizers become stronger. The advent of the drum coater meets their needs. It adopts powder or liquid coating process, forms a protective film on the surface of the granular fertilizer. It can effectively prevent fertilizer granules from clumping, nutrient loss, and make particles more glossy. So it can increase the competitiveness of your fertilizer on the market and help you earn more profits.

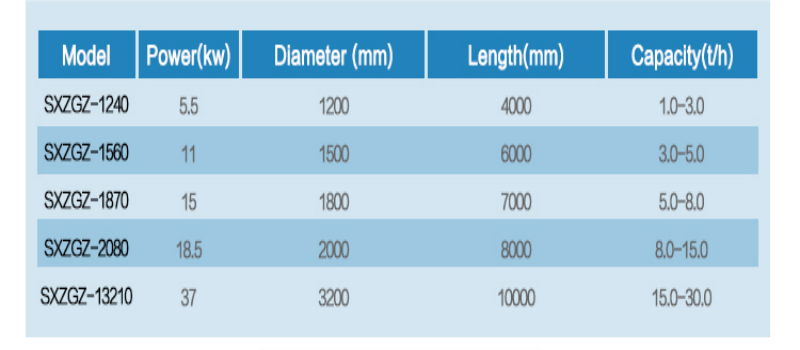

Main Parameters

- Capacity: 1-20 t/h

- Equipment Material: Carbon steel, stainless steel

- Pricing:$3,500-$10,000(Reference)

- Function: color change, moisture-proof, nutrient adding, improve appearance, etc.

- Application: organic and compound fertilizer granules

Why you need rotary drum coating machine in granular fertilizer production?

After fertilizer drying and cooling, you will find that there are still problems with the fertilizer particles. Such as caking, uneven appearance and nutrient loss. But using rotary coating machine can keep you away from these troubles. It can improve granular fertilizer quality from various aspects.

Make granule not easy to cake

If the fertilizer granules are exposed to the air for a long time. They will absorb moisture from the air and become easy to clump. Using rotary coating machine can solve the problem perfectly.

Prevent nutrient loss

Rotary coating equipment enables the surface of fertilizer particles to form a layer of protective film. It can prevent fertilizer pellets from nutrient loss.

Improve fertilizer utilization

After coating, the fertilizer will more slowly release the available nutrients to the soil. It contributes to improving fertilizer utilization.

Improve pellets appearance

During the coating process, the coating agent will fill the small pits on the surface of the particles. It makes the fertilizer pellets become more smooth and glossy.

No pollution

The coating on the fertilizer pellet makes it not easy to disperse. This can reduce the dust when the workers move fertilizer bags.

Whether you want to produce granular organic or compound fertilizer, coating machine is essential for you. If you need more details about it, you can contact us.

What materials are suitable for coating granular fertilizer?

Besides coating machine, coating materials are also important in fertilizer production process. There are many types of coating materials, mainly including sulfur powder, gypsum, resin, paraffin, asphalt, etc. So how to select suitable coating materials? There are two tips for you:

The coating material you choose must not be harmful to the soil. This is the most important rule you must obey. Harmful coating materials not only reduce soil quality, but also endanger human health.

You should choose the coating materials according to your needs. If you need a more economical coating agent, sulfur and gypsum are optimal choices for you. Their cost is not high and they can help crops grow by increasing the nutrient content of fertilizers. But if you want to slow down nutrient release of fertilizer, resin, paraffin and asphalt are more suitable for you.

How does rotary coating equipment work to improve fertilizer quality?

After choosing the coating material, you need to make it into powder or water solution and place it in the spray device. Then you need to transport fertilizer granules to the drum. The spray system will add the coating agent to the drum. At the same time, with the drum rotating, the coating agent evenly adheres to the fertilizer particles. Then the coating agent will form a protective film on the surface of fertilizer pellets. The protective film can isolate the air, prevent fertilizer from caking and nutrient loss.

The dosage of fertilizer coating agents is low. Therefore, you don’t need to dry the coated fertilizer pellets again. Of course, the cooling process is not necessary either.

Construction of the drum coating equipment

In order to process the fertilizer granules with high efficiency. Our engineers improve every part of the rotary coating machine.

Bracket

The bracket supports the whole machine, and is under a large pressing force. And there is a large friction between the bracket and the body. So our engineers use anti-corrosion and wear-resistant materials to manufacture the bracket. It can greatly increase the service life of the fertilizer machine.

Rotary drum

The main body of the coating machine is a rotating drum. When the cylinder rotates, the granular fertilizers collide and rub against each other. During this process, the coating agent will continuously fill the small cracks on the surface of the granules. Therefore, the fertilizer pellets will become smooth, glossy and not easy to stick.

Transmission parts

This part consists of motor, pulley,V-belt and the reducer. When the drum coating machine is set in motion. The motor drives the pulley, the V-belt and the reducer to move. Next, these devices will drive the main shaft to work.

Outside big gears

They are fixed on the machine body. When the drum rotating, it will ratchet with the small drive gears, to drive the machine body to work. If you want to make it work more freely. You should pay attention to lubricate the gears after finishing the production.

I want to buy fertilizer coat machine immediately!

Why so many fertilizer manufacturer want to buy rotary drum coating machine?

Beside improving fertilizer quality, rotary coating equipment still has various advantages. For example:

Long service life: Made of high-strength and wear-resistant materials. It reduces the wear caused by working for a long time. So it has a long service life.

Wide application: It is suitable for various materials. Whether you want to produce cow dung manure fertilizer, chicken manure fertilizer or NPK fertilizer. You can use it in your fertilizer production line.

Various types: In order to meet different needs from customers, we design rotary coating equipment with various capacities. From 1 t/h to 30 t/h for your choice, fully meet your needs. Whether you want to start a small, medium or large scale fertilizer production.

Ideal price: Direct sales from factory, no extra charge. We can provide you a high quality rotary coating machine at an optimal price.

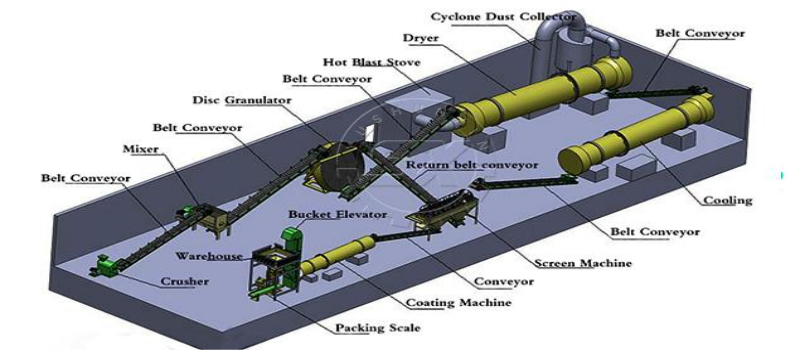

A fertilizer production line consists of various equipment. Besides drum coating machine, it also encompasses batching machine, composting equipment, crusher, mixer, granulator, drying machine, cooling machine, etc. You can choose according to your needs. Shunxin Engineering Equipment Co., Ltd can provide you with whole set of equipment in the fertilizer production line.