If you want to process chicken manure in your farm, making it into organic fertilizer is an ideal choice for you. Because it is rich in nitrogen, phosphorus and potassium, which are necessary for the growth of crops and plants. But how to convert chicken dung to organic fertilizer? For this, SX especially designs various fertilizer machines to help you produce organic fertilizer from chicken dung quickly. In addition, SX can provide you with a variety of business plans for chickenmanure fertilizer making. Such as chicken poop composting system, small scale chicken dung fertilizer preparation line, large scale chicken dropping processing system, etc. You can find the most suitable way to produce your own chicken litter organic fertilizer.

Main Paramaters

- Capacity: 1-20 t/h

- Final shape: Powder or granule

- Final granule size: 1-10 mm

- Application: Chicken farm manure management, organic fertilizer making.

- Equipment types: compost machine, granulator, dryer, crusher, mixer, screener, packaging equipment, etc

Can I add NPK to chicken manure fertilizer making process?

How to process chicken manure into powder organic fertilizer?

When you want to make chicken manure into organic fertilizer in a simple way, we recommend you turn it into powder fertilizer. And a complete powdery organic fertilizer production system usually contains the following steps:

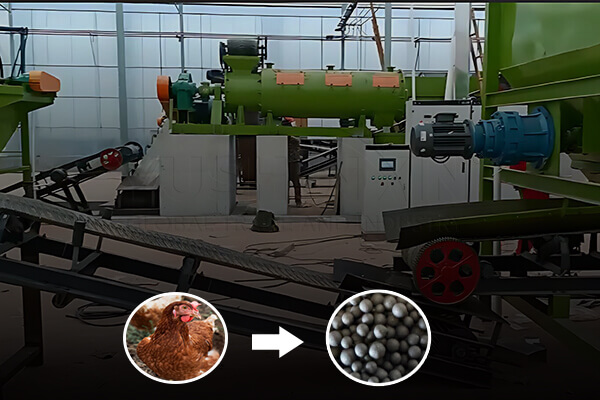

How to make chicken dung into organic fertilizer pellets?

But a large amount of fertilizer manufacturers prefer to process chicken waste into granules. Because granular chicken dung fertilizer is more convenient to transport, store and use. Then how to convert broiler manure into pellets? First, it is necessary to make it into powder fertilizer. Then on the basis of it, you also need the following steps:

2 popular business plans for chicken manure fertilizer production

After understanding the process of making organic fertilizer from chicken manure, you should consider which type of equipment is suitable for your chicken manure processing system. That is, how to design your chicken waste fertilizer production business plan? For this, there are two kinds of popular business plans of chicken manure fertilizer preparation for your reference:

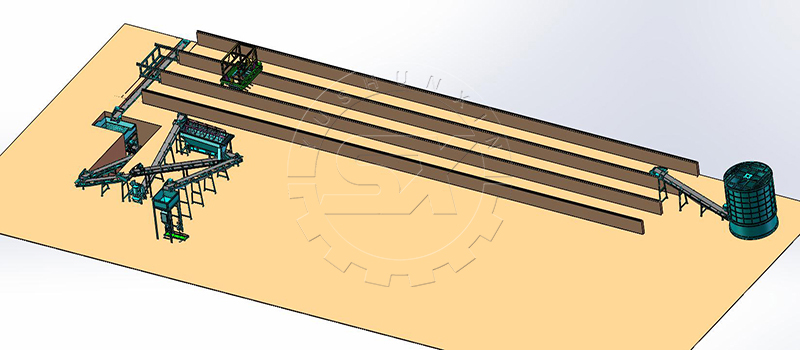

Small scale chicken manure fertilizer processing business plan

Composting machine for small scale chicken manure processing

If you want to start a small scale chicken litter processing, we recommend you choose groove type compost machine. It has a turning width of 2 m-5 m and a turning depth of 1-2 m. So it can meet your requirements for small scale composting. In addition, it has a economical price, which is about$6,500-$19,000.

Granulator for making pellets from chicken dung in a small scale

When it comes to small scale granule making machine of chicken manure, disc granulator is an ideal choice for you. Because it has a capacity of 1-6 t/h, which is suitable for processing chicken litter in a small scale. Moreover, it has characteristic of low cost, adjustable granules size, less area occupation, etc.

Other equipment choosing for small scale chicken waste fertilizer making

Then besides the above two main machines, you can equip your small scale chicken dung fertilizer making line with some auxiliary machines. Including static batching machine, semi-wet material crusher, disc mixer, SXHG-1010 rotary dryer, SXLQ-1010 drum cooler, BM1200×4000 coating equipment and single bucket packing scale.

Price and area occupation of this small scale chicken poop process line

And the price and area occupation are also items many fertilizer suppliers pay attention to. Generally, the price of a complete small scale organic fertilizer making line of chicken manure is $110,000-$190,000. Meanwhile, its area occupation is about 2,000-4,500 ㎡.

Is there succussful case of small scale chicken manure processing for reference?

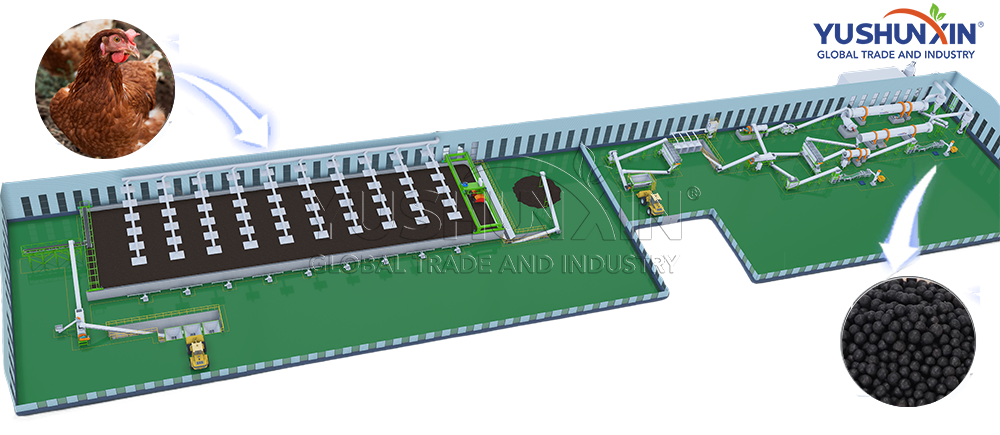

Large scale chicken dung fertilizer manufacturing project design

Composting machine for large scale chicken litter processing

Provided you has a large scale of chicken dung need to process, it is advisable to buy wheel type compost machine for your fertilizer production project. Because it has a larger output than other chicken poop composting machines. Its turning pan can reach 10-30 m and turning depth is 1-3 m. In addition, it has an electrically automatic control system. Therefore, it can help you finish large scale fermentation of chicken droppings easier and faster.

Granulator for producing pellets from chicken dung in a large scale

For large scale chicken manure fertilizer granulation, rotary drum granulator will be your best option. There are two reasons. For one thing, it has a large capacity, which can reach 30 t/h. For another, it has a high performance in corrosion resistance. We not only produce it with high strength alloy steel, but also add a rubber lining to the rotary drum pelleting machine. So it can withstand the erosion of a large amount of chicken manure processing.

Other equipment choosing for large scale chicken waste fertilizer making

When you want to enlarge your chicken dung fertilizer making scale, it is necessary to replace your auxiliary equipment with a high capacity one. For this, we recommend you buy dynamic batching machine, new type vertical crusher, double shafts horizontal mixer, SXHG-2020 dryer, SXLQ-1010 cooler, BM1600×6000 coating machine and double bucket automatic bagging equipment.

Price and area occupation of this large scale chicken manure process system

In general, the price and area occupation of chicken manure fertilizer manufacturing will rise as the increasing of capacity. Therefore, a complete system of making chicken manure into fertilizer in a large scale costs $360,000-$550,000. And it needs a 2,000-4,500 ㎡ place to install.

Besides the above business plans for chicken dung fertilizer manufacturing, we also can provide you with many other fertilizer making project designs for your choice. Such as cow dung fertilizer making line, biofertilizer production system, etc. You are sure to find the one you want!