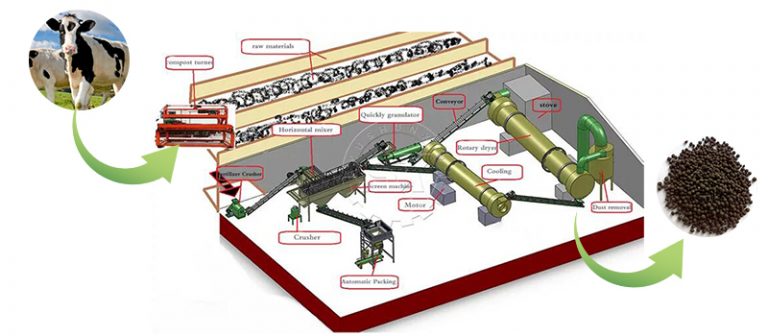

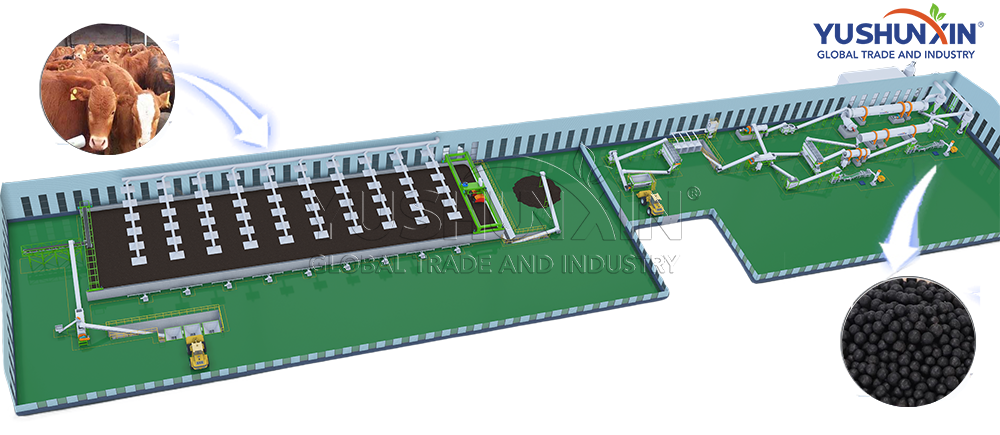

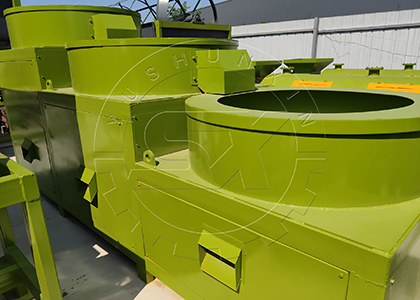

Cow dung fertilizer machine, as the name suggests, is designed to make cow manure into fertilizer quickly and easily. Usually, it contains compost machine, granulation equipment, batching machine, crusher, mixer, dryer, cooler, coating machine, packaging and conveyor. You can choose them according to your budget, capacity, final shape, factory area, etc. YUSHUNXIN, as a professional fertilizer making machine factory, can provide you with quality cow waste fertilizer equipment at a economical price. In addition, we can offer you free customized design for your cow dung management plan. We will try our best to help you start your cattle manure fertilizer making successfully.

Main Parameters

- Capacity: 1-20 t/h

- Area: 800-10,000 ㎡

- Cost: $30,000-$550,000

- Equipment types: compost machine, granulator, dryer, crusher, mixer, screener, packaging equipment, etc

- Equipment material: Q235 Carbon steel or stainless steel

- Application: Cow farm manure management, Solid organic fertilizer making.

How to choose right equipment for cow manure fertilizer making?

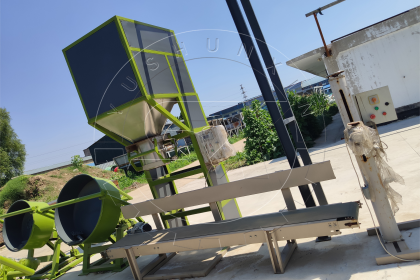

What equipment is suitable for small scale cow dung powder fertilizer production line?

If you want to start small scale cow dung fertilizer production at a low cost, YUSHUNXIN can provide you with a small scale cow dung powder fertilizer production line. It doesn’t need many manufacturing machines, only contains:

- Dewatering machine: For fresh cow dung contains too much water, which will hinder the production of cow dung fertilizer. Therefore, the first important thing you should do is to use our cow dung dewatering machine to control the water content under 65%.

- Composting machine: Composting is necessary for organic fertilizer making, of course including cow dung fertilizer production. Because it can kill harmful bacteria, pest eggs, grass seeds in cattle litter. For fast cow manure composting, we can offer you professional fermentation machines for your choice.

- Forklift Feeder: After compost production, you need to transport cattle manure compost to forklift feeder. Which can filter big stones and grass and feed compost into powder fertilizer making system.

- Crusher: Crusher can grind cow poop compost into fine powder. It makes final cattle waste fertilizer easier to transport, store and use. You also can use it before compost to enlarge the contact area with oxygen to facilitate cow manure fermentation. Here, both vertical crusher and semi-wet crusher are ideal choices for you.

- Powder packing machine: If you make powder fertilizer from cow manure for commercial purposes, it is advisable to package them with packing machine. In this way, you can transport and store cow dropping fertilizer easier.

- Powder screening: In this process, screening machine will distinguish the fine powder from agglomerate and waste (such as cigarette butt, small stones). And unqualified cattle manure fertilizer is transported to crush again.

In this fertilizer production project, you do not need the fertilizer granulator, dryer and cooler to make fertilizer granules. Because of lacking these cow dung fertilizer machines, the final products are powdery. And it can greatly reduce your budget for organic fertilizer making. But there is no adverse effect on the final cow poop fertilizer quality. You can use the powdery fertilizer on your farm or package them for sale. Therefore, you do not need to buy it from others. Meanwhile, you can make money from this simple organic fertilizer production line.

How to make cattle manure into organic fertilizer granules?

If you are make fertilizer out of cow manure in commercial purpose, it is advisable to prepare cow litter into granular organic fertilizer. Because it is convenient for transport, storage and use. for this, SX can offer you customized plan for cow dung pellets production. It can help you turn cow manure into commercial organic fertilizer effectively. Granular organic fertilizer manufacturing sysytem of cattle manure is based on powder fertilizer making line. Besides the above organic fertilizer machines, it also needs following steps:

- Mixing dry cow dung with other organic wastes. Heavy cow manure should be mixed with organic substances like vegetable waste, garden debris, dead leaves, sawdust, wood ash, hay and straw etc. Using a mixer can makes this work more quickly.

- Granulating process. Remember to choose a suitable organic fertilizer granulator according to the scale of cow manure fertilizer manufacturing.

- Drying the fertilizer granules. Usually, in order to easy packaging and storage, a rotary dryer would be used to evenly dry the granules and ultimately create a uniform and quality final product.

- Package. This the final process of organic fertilizer making line of cow droppings. Here SX can provide automatic packing machine for you to fulfill high-efficiency, automatic and convenient packaging and bagging solution for finished cow dung organic fertilizers.

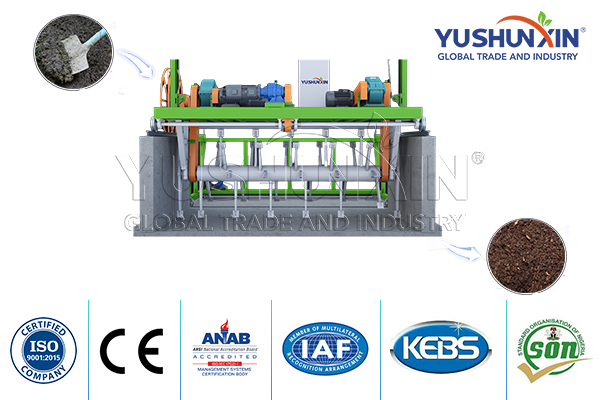

What equipment can be used in cow manure composting?

When you want to start cow waste composting, you can there are many types of composting machine on the market. Then which is the most suitable one for you? In general, these fertilizer composters can be divided into 3 types. Trench working compost turner, windrow compost turner and in-vessel fermentation tank. They can fully meet your requirments of 1-30 tons of cow manure compost making at a economical investment.

Trench working compost turner for sale

Groove composting (or trench composting) is widely used in cattle breeding farms management. Using this method, you can compost cow waste in an easier way without waiting for natural decomposition. But only collecting cow manure and stacking them together in the trench is not groove composting. You need to turn the raw materials to make them fully fermented. For this, we recommend you to choose wheel type compost turner or groove type compost turner.

Wheel type compost turner

Wheel type compost turner is suitable for starting a large scale fermentation of cow manure with low cost. Because its turning width can reach 10-30m, and turning depth can reach 2m. So you don’t need to build too many trenches and reduce the cost on infrastructure projects. In addition, the double-wheel design can help you compost more quickly. And hydraulic lift design allows you to easily raise the wheel and quickly return the compost turner to the starting point to change slot. These operations can be remotely controlled, so you will spend less on the labor force.

Groove type compost turner

If your budget on fertilizer composting equipment is not enough, you can choose groove type compost turner. It is suitable for the trench with a width of 3-6m. If you want to enlarge the fermentation scale of cow manure fertilizer, you only need to increase the number of grooves. We can provide you with the transfer vehicle to realize the multi-groove working. In the process of cow dung composting, it can keep the temperature of the materials between 65℃-70℃, the optimal temperature for fertilizer fermentation. So you can ferment and decompose the cow dung quickly.

| Equipment | Turning Width (mm) | Turning Depth (mm) | fermentation method |

|---|---|---|---|

| Groove Type Compost Turner | 2500-5000 | 800-2000 | Fermentation Groove |

| Wheel Type Compost Turner | 8000-30000 | 1500-3000 | Fermentation Groove |

Windrow compost turner

If you don’t want to spend money on groove building, you can choose windrow compost turner, which can compost cow manure on the ground. Windrow composting is a good way for cattle farmers to make organic cow dung compost in their own farm. By paving the raw materials in long windrows and equipping a windrow compost turner, you will get organic cow manure compost within 20 days. If you’re afraid that rain will affect the quality of your compost, you can build a greenhouse to protect the windrows. In this case, SX can offer you crawler type compost turner and moving type compost turner for windrow composting.

Crawler type compost turner

When you want to buy an easier operated windrow compost turner for cow manure processing, we will recommend you crawler type composter. It doesn’t require the steering wheel, the driver simply controls two bars, then the machine can turn left or right, brake and 180 degrees turn around. And it adopts hydraulic balance technology, which make it can automatically raise and lower the height of compost turner shaft. So it can compost fertilizer piles at high speed according to the moisture degree of the material. In addition, it is equipped with soft start turning clutch, which can reduce the damage to chain, bearings and shaft. And front hydraulic push plate design can greatly save the space, time, diesel, manpower and shorten the cattle litter fermentation period.

Moving type compost turner

But if you need a more flexible windrow compost turning machine, you can buy moving type compost turner. It adopts four wheel walking design, which can move forward, backward and turn freely. And it only needs one worker to operate. During the cow manure fermentation process, the machine rides astride above the pre-piled strip fertilizer bases. Then the rotary blades mounted on the shaft will mix, fluffy and move the strip fertilizer bases along with the movement of the moving type compost turner. So that makes the fertilizer bases forming into new strip stacks. This can effectively and evenly mix the viscous cow manure with straw powder and other materials, so that creates a better aerobic environment for cow dung fermentation.

| Equipment | Turning Width (mm) | Turning Depth (mm) | fermentation method |

|---|---|---|---|

| Crawler Type Compost Turner | 2000-3000 | 800 | Windrow |

| Moving Type Compost Turner | 2500-3000 | 600-1500 | Windrow |

In-vessel fermentation tank

If you are desirous of composting cow manure in an environmentally friendly way or don’t have enough space for open fermentation. In-vessel fermentation tank is your best choice. Only 10-30㎡, it can help you finish cow dung fermentation within 20 days. And it is equipped with waste gas treatment system, so there is no secondary pollution in the process of cattle waste composting. In SX, there are 2 types of in-vessel fermentation tank for your choice. Horizontal fermentation tank and vertical fermentation pot. The former is more suitable for compost cow litter with a volume less than 50m³, the latter is an optimal choice for larger amounts of cattle manure fermentation – 50-150m³.

| Equipment | Vertical Ferementation Tank | Horizontal Fermentation Tank |

|---|---|---|

| Capacity (m³) | 50-150 | 5-50 |

| Area (㎡) | 10-30 | 15-30 |

| Fermentation Method | In-vessel Fermentation | In-vessel Fermentation |

Moreover, if you want to further compost cow dung quickly, you can choose to adjust the C:N ratio, temperature, adding fermentation agent, etc. Only send us your requirement for cow manure processing, we can provide you with the best solutions.

Inquiry the in-vessel compostor for cow manure fermentation!

How to choose right equipment for making cow dung compost into granules?

If you want to improve the quality of your cow manure fertilizer, making it into granules is an excellent choice for you. After granulation, the contact area between cow dung fertilizer and air will become smaller, so it is not easy to absorb moisture and agglomerate. Therefore, it is more convenient for transport and storage. In addition, the granular fertilizer is less likely to be blown away by the wind, so the utilization rate of your cow manure fertilizer is higher. There are various cow manure granulating machines in SX for your choice. Among them, disc granulator and rotary drum pelletizer are popular with cow dung fertilizer manufacturers.

Disc granulator machine for small scale cow dung fertilizer granulation

If you need a granulator to make cattle litter fertilizer in a small scale, pan granulating machine is an excellent choice for you. It can produce 1-6 tons of fertilizer per hour. So it is suitable for you, if your ideal annual output is below 40,000 tons. And another reason why the pan pelletizer is so popular is that it has a high granulating rate. The granulating rate of pan granulator can reach 93%. It means you can get more fertilizer pellets with the same amount of materials. Moreover, the pan granulation machie is also an ecnomical option for you. It is made of high quality alloy steel, which has a high performance in corrosion resistence. And compared with other pelletizers for cow dung processing, it has a more favourable price. Therefore, if you want to turn cattle litter into granules at a low cost, we commend you choose it.

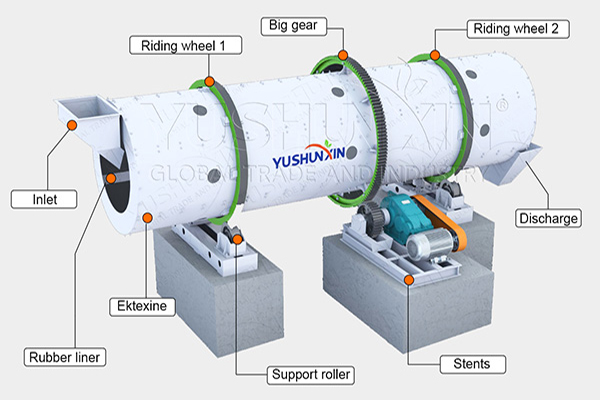

Rotary drum pelletizer for large scale cattle litter processing

If you plan to start a large scale fertilizer production, rotary drum granulator is an ideal choice for you. It has a model of SXZGZ-3210, which has a capacity of 15-30 t/h. It can fully meet your needs to prepare fertilizer in a large scale. If you need rotary drum granulators with other capacities, we can also provide for you. In addition, rotary drum granulating equipment also has many other elaborate designs. They can offer you a better fertilizer granulating experience. First, it adopts the one-piece drum, which is not broken after long time usage. And its lining is made of anti-corrosion rubber, which can prevent materials from sticking to the inner wall. So it will be the best choice for those who want to build a large fertilizer plant.

| Equipment | Capacity (t/h) | Granule Size(mm) | Granulation Method |

|---|---|---|---|

| Pan Granulator | 1-6 | 1-8 | Wet Granulation |

| Rotary Drum Granulator | 1-30 | 3-6 | Wet Granulation |

Learn more about cow manure fertilizer granulators!

How to make fertilizer pellets looks more beautiful in cow dung fertilizer making?

As for this question, it is very normal in fertilizer industry, especially in commercial fertilizer production. Because beautiful shapes can make a lot of client to buy for professional and advanced technology. In terms of the problem, our engineers design organic fertilizer polishing machine to meet your needs. Although it belongs to auxiliary equipment, its use for fertilizer pellets making is necessary. It is a circular polishing device based on organic and compound fertilizer granulator. Meanwhile, it makes the cylindrical particles roll to ball without return materials. And then, it has high ball rate, good strength, beautiful appearance and strong practicability. By fertilizer polishing machine to some extent, it can prompt the fertilizer sales. Why not use it as soon as quickly. Pl ease contact us in time.

Other equipment used in cow dung fertilizer manufacturing

Besides fermentation equipment, there are many other equipment can help you in successfully turning cow dung into organic fertilizer. For example:

Drying machine and cooling equipment

Moisture content is also an item focus on when making organic fertilizer with cattle waste. Usually, the water content of final cow manure fertilizer need to reach below 14%. But after granulation, it usually is 20%-35%, which is higher than international standard. Here, YUSHUNXIN drying machine and cooling equipment can help you remove excessive moisture from your organic fertilizer particles.

Fertilizer screener

When you make fertilizer out of cow dung, you will find that not all finished products are qualified, some need to be reprocessed. But how to separate qualified and unqualified fertilizers? Fertilizer screener is designed for it. SX machinery can provide you with powder rotary screening machine and granule rotary screening equipment. You can choose according to your needs

Packaging machine

Packaging is the final step in the process of making cow manure fertilizer. After packaging, the fertilizer will be easier to transport, store, sell and use. In general, fertilizer suppliers will pack fertilizers into 20kg/bag or 50kg/bag to meet the different needs of users. For this, we can provide you with automatic quantitative packing scale. It contains single bucket packing scale and double bucket packing scale. They can fully meet your needs.