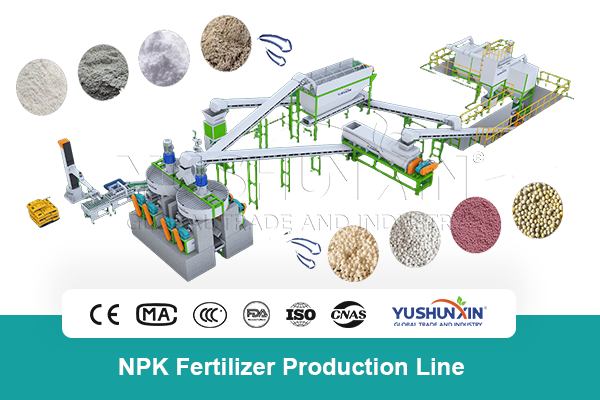

NPK fertilizer production line is a kind of compound fertilizer production line. It can help you produce high quality NPK fertilizer with required proportion. In general, there are two hot sale NPK preparation plans for industrial fertilizer manufacturers. They are NPK fertilizer granulating line and bulk blended NPK fertilizer system. Whether your budget for NPK fertilizer project is $500,000 or $30,000. Whether you requires a solution with high profits in a long term or fast return. YUSHUNXIN will offer you customized design.

NPK Granulation Line

| Capacity | 1-20 t/h |

| Application | Chemical powder to NPK granule |

| Design | Batching machine, crusher, mixer, granulator, screen, packager, etc. |

| Equipment material | Carbon steel Q235, Alloy |

| Voltage | 220v/380v/415v/440v/480v(50Hz/60Hz) |

NPK Bulk Blending Line

| Capacity | 5-40 t/h |

| Application | Chemical granules to NPK fertilizer |

| Design | batching machine, BB fertilizer mixer, packing machine |

| Equipment material | Carbon steel Q235, Alloy |

| Voltage | 220v/380v/415v/440v/480v(50Hz/60Hz) |

How much does the NPK compound fertilizer making line cost?

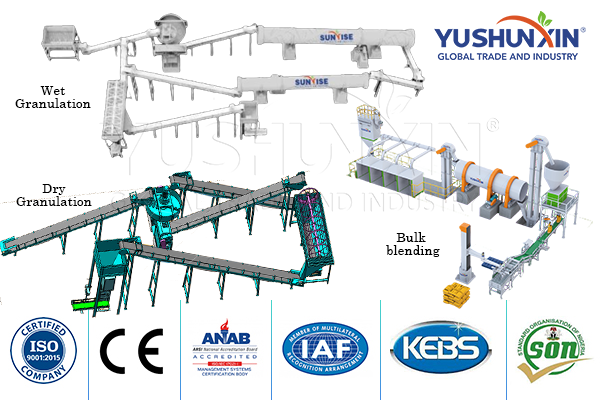

Top 2 industrial NPK fertilizer production lines for your choice

Commonly, to start a NPK fertilizer making business, you can choose to produce NPK granules and blended NPK fertilizer freely. The former can help you make more profits in a long term while the latter is the best choice for faster getting back your investment in NPK fertilizer production project.

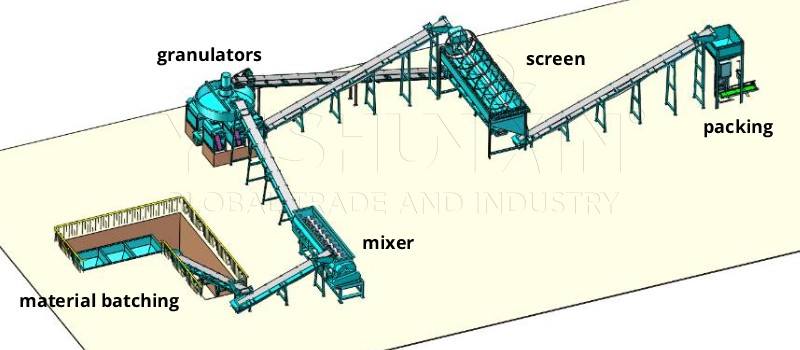

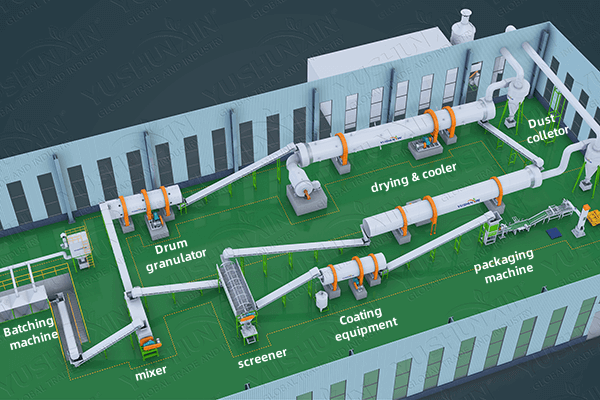

Profitable NPK fertilizer granulating line

If you want to produce NPK fertilizer with higher value, it is an ideal choice to buy a powder granulation line. With multiple processing steps, you can make quality granular NPK fertilizer with balanced nutrients, better release and longer storage. So, you can earn more in a long term operation of the NPK granulation plant.

This system contains the steps of batching, crushing, mixing, granulation, drying, cooling, screening, coating and packaging.

- Accurate batching is the basis of strictly producing NPK according to your formula.

- Crushing and mixing contribute to the production of uniform nutrient contained NPK.

- Granulating, drying, cooling provide it with a lower possibility of sticking.

- Coating can improve its release effect and appearance.

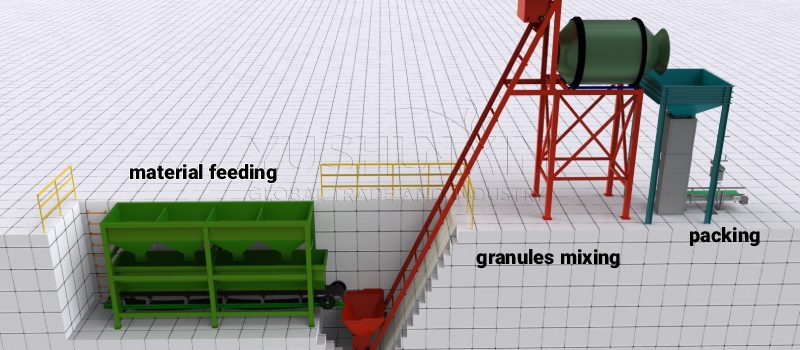

Fast return NPK blending fertilizer line

But if your budget for NPK fertilizer making is limited, we recommend you to choose NPK blending fertilizer line. It is also known as a bulking blending production line. With only a $100,000 cost for NPK fertilizer making project, you can start an blended fertilizer making operation of 20TPH. Here, it can bring you investment return with 1-2 years.

It work by batching, mixing and bagging, only 3 steps, to make high quality industrial NPK fertilizer for you. Simpler process means less space occupation and fewer NPK fertilizer machines employment. So you can start NPK fertilizer preparation at a lower cost.

Can it produce NPK fertilizer in large scale? Of course, the largest capacity of our NPK bulk blending line can reach 100 t/h. Moreover, whether you want to prepare NPK compound fertilizer of 15-15-15 or 20-10-10, it can fully meet your needs.

Which powder granulating process is better for you to make NPK fertilizer?

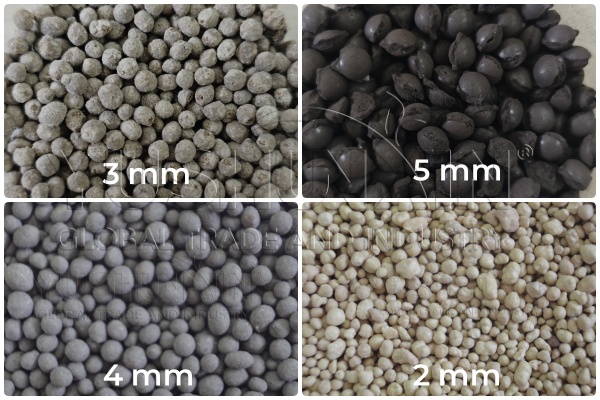

For NPK pellets making, there are two fertilizer granulation processes are commonly used for manufacturers. Dry granulation technology and wet granulation method. They can fully meet your requirements for granular NPK fertilizer production line with 1-20 TPH capacities, 1-10 mm granules, $50,000-$500,000 budgets, 500-10,000 ㎡ area occupation, etc.

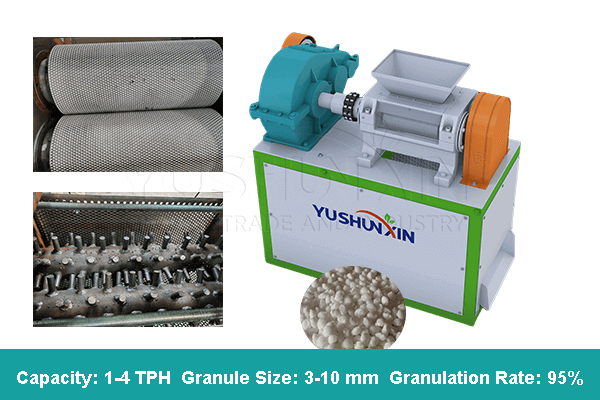

Dry granulation technology of NPK powder

If you need an industrial NPK compound fertilizer granulation line 1-10TPH output, lower cost, and a limited area, the dry granulation technology of double roller press extrusion can meet your needs. With less than 10% moisture NPK powder, the roller press granulation line granulate it mainly by mechanical pressure. Namely, there is need to add water and dryer, cooler to your NPK fertilizer granulation plan. Therefore, for 1-20 TPH compressed granular NPK fertilizer production line establishing, you only need to prepare a budget of $50,000-$300,000 and an workshop of 800-3,500 ㎡.

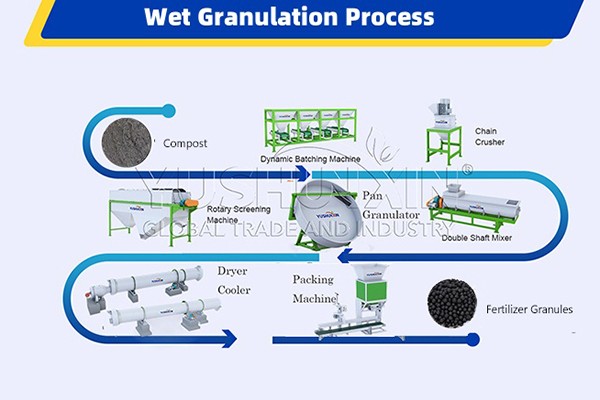

Wet granulation method of NPK compound fertilizer

But, for those who want to make NPK fertilizer into granules in a large scale and with more balanced nutrient, round ball shape,etc, the systems adopts wet granulation method are your excellent option. With natural rotation granulation, it can process a large amount of NPK powder into spherical fertilizer pellets perfectly while deeply materials mixing. At the same time, during the granulating, it uses water and liquid additives as binders help you granulate NPK fertilizer quickly and adjustable size of 1-8mm freely. Here, YUSHUNXIN can offer you both pan pelletizing system with over 93% granulation rate and rotary drum granulation plan of maximum 30 TPH capacity. As for NPK fertilizer making cost and land, it requires about $300,000-$500,000 costs and a 4,000-10,000 ㎡ workshop.

Or, you needs any other requirements for NPK fertilizer granule manufacturing, YUHSUNXIN also can offer your customized solutions, come to get it now!

Can you offer $50,000 cost solutions for NPK fertilizer plant setup?

Yes, absolutely. As a professional manufacturer specializing in fertilizer-making solutions and equipment, YUSHUNXIN provides flexible and cost‑effective NPK fertilizer production plans tailored to your specific budget and capacity requirements. For clients aiming to invest around $50,000, we can design several practical options that balance production efficiency, automation level, and output scale.

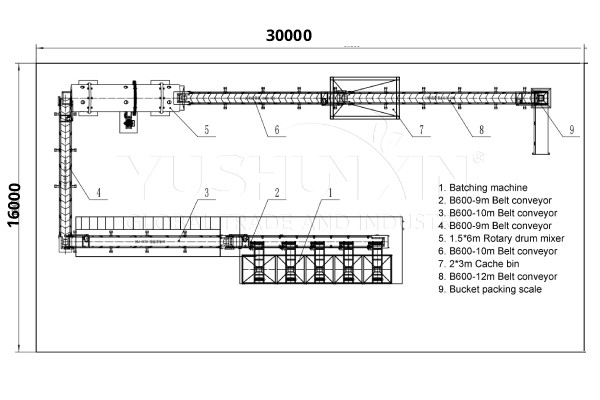

10TPH blended NPK fertilizer system

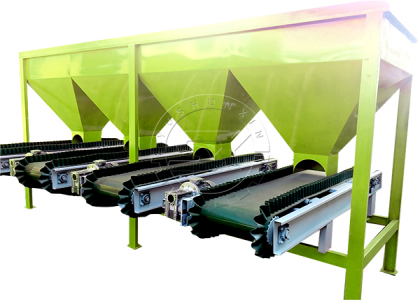

When you want to set up an automatic NPK fertilizer making line in a large scale, it is the best operation to buy a granules bulk blending system. There is a complete configuration of dynamic batching machine (customized hoppers of 2-6 or more),5*6m rotary drum mixer, cache silo, bucket bagging machine and conveyors. Of course, the whole system is controlled by PLC container, which help you produce NPK compound fertilizer with fewer workers.

5TPH NPK fertilizer granulation line

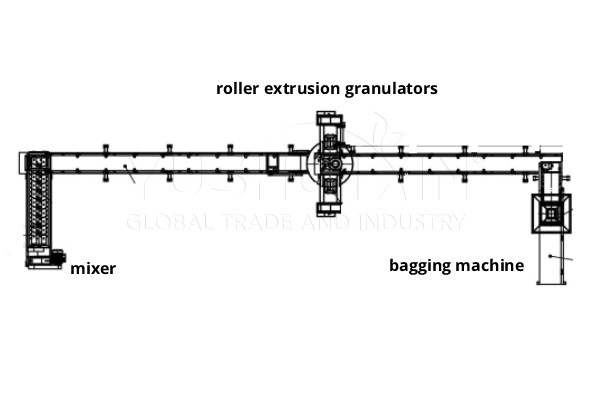

Can we produce NPK pellets from powder with a $50,000 investment in equipment? Of course. You can set up a semi-automatic double roller granulation line. It only contains NPK fertilizer equipment of SXSJ-0830 double shaft mixer, SXJP-2500 disc distributor, SXDG-2.5T roller extrusion granulator*2, granule packaging equipment, and conveyors. You can choose to upgrade the NPK pellet making system in the future.

How to improve the accuracy of NPK fertilizer batching?

The soil and crops in each region are different. So the needs for nutrient of N, P and K are different. Therefore you should prepare NPK compound fertilizer in a certain proportion. It is decided on the basis of the investigation. So the accuracy of NPK fertilizer feeding is essential. There are some NPK machines can help you in this aspect.

Dynamic automatic batching machine

Provided you want to increase the NPK powder feeding accuracy of NPK fertilizer granulation line. The dynamic automatic batching system is an optimal option for you. It usually uses electronic belt scale or nuclear scale as measure equipment. And the host has PID regulation and alarm function. It can provide you with continuous batching without intermediate stop. So it can meet the strict requirement for various materials proportioning.

BB fertilizer mixer in NPK fertilizer blending line

During the NPK fertilizer blending process, there is another equipment can help you improve the accuracy of batching. It is BB fertilizer mixer, which plays an important role in making high quality NPK fertilizer. It overcomes the mixture chromatography and distributaries phenomena. Which are caused by different proportion of raw materials and particle size. Then material properties, mechanical vibration, air pressure, voltage fluctuation and cold weather can no longer affect the system. So only waiting for 3-5 mins, you can get NPK fertilizer you need.

Other equipment you can choose to improve NPK fertilizer quality

Besides the NPK equipment mentioned above, there are many other fertilizer processing machines for your choice. They can help you produce better NPK fertilizer.

Rotary screening machine for granules classification

After cooling, you will find that not all NPK fertilizer pellets meet your requirements. You need to screen out the qualified products and make unqualified granules go through granulating again. At that time, rotary screening machine can help you finish the task easily.

Fertilizer coating machine for NPK pellets

If you want to further improve your npk products quality, coating is an excellent option for you. It will add a protective film to the surface of the NPK granules. The protective film can prevent sticking and nutrient loss. So the npk pellet will become easier to transport and store. For this, we can provide you with drum coating machine.

Packaging equipment for sale

It is essential for you to make commercial NPK fertilizer. Whether you choose to turn the materials into pellets or only mix them evenly. After packing, the NPK fertilizer will become easy to transport and store. In this process, we recommend automatic packing scale to you.

Advantages of NPK pellet making line in SX fertilizer equipment factory

Low cost

We can provide you with a NPK fertilizer production line with an ideal price. Because Shunxin is a source factory of fertilizer equipment. And we can design a NPK fertilizer project out of charge according to your budget. These can greatly reduce your production cost.

Long service life

All NPK processing equipment we provide you are made of high quality materials. Moreover, we will offer guidance to you. Including how to use the fertilizer equipment correctly and how to maintain it. They are important in prolonging the service life of the NPK equipment.

Easy operation

Only employing several workers, you can keep the entire production line running. Because the NPK machine system has the characteristic of high automation. The smallest NPK fertilizer line in our company only needs 3-4 workers.

Produce high effective fertilizer

It adopts advanced technology and reasonable design. These are in favor of strictly producing NPK fertilizers in the required proportions. So the finished fertilizer contains rich nutrient, including nitrogen, phosphorus and potassium and other elements. And it can efficiently promote crop growth.

What do you need to tell us if you want to buy a NPK fertilizer making line

If you are interested in NPK production line or NPK machine or you want to buy other fertilizer equipment. You can contact us to tell us some information about you or your company. The more information we know, the better design project we can provide you. It includes your country, materials, capacity, factory space, which fertilizer production line or equipment you need, etc. In addition, you need to tell us your name, telephone number and email. So we can contact you for further discussion. We will design an ideal layout according to your requirements.

Past cases of NPK fertilizer manufacturers

Now we have help many NPK fertilizer manufacturers start their NPK fertilizer preparation successfully. Whether it is small or large scale, NPK powder to granule or NPK blend fertilizer making, etc. Some cases are here for you reference.