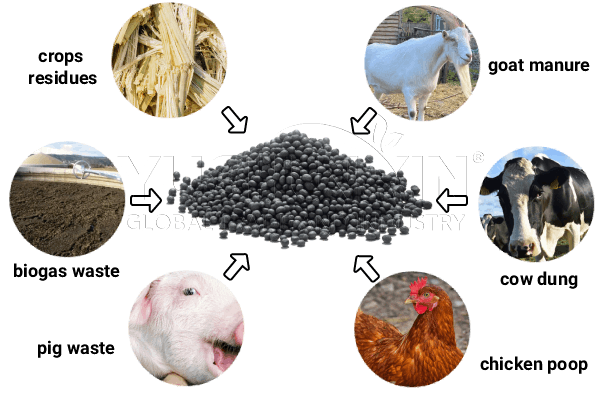

Fertilizer granulator machine is an important part in both organic and compound fertilizer production line. Because it can powder materials into fertilizer granules quickly. And the granulated fertilizer has features of easy transport, storage and long effect, which help you make more profits from fertilizer production business. As a professional fertilizer equipment manufacturer for nearly 20 years, YUSHUNXIIN has developed various kinds of fertilizer granulation machines for your choice. They can fully meet your requirements for making organic and NPK pellets with 1-30 t/h capacity, 1-10 mm size, etc.

Main Parameters

- Capacity: 1-30 T/H

- Granule Size: 1-10 mm

- Granule Shape: Round ball, flat ball, culumn. etc

- Granulation Rate: 90%-95%

- Equipment Price: $3,000-$70,000

- Equipment Material: Carbon Steel, Alloy (Customized)

- Application: animal manure, biogas residue, NPK pellets, Phosphate fertilizer granules, etc

Top 6 types of Popular fertilizer granulator machines for your choice

In general, YUSHUNXIN have 6 types of fertilizer granulation machines on sale for your choice. They can fully meet you requirements for fertilizer pellet making in large and small scale, 1-10 mm size, low or high budget, etc.

| Equipment | Capacity (T/H) | Granule size (mm) | Feeding Moisture | Application |

|---|---|---|---|---|

| Disc Pelletizer | 1-6 | 1-8 | 20%-40% | Organic, Compound |

| Rotary Drum Granulator | 1-30 | 3-6 | 20%-40% | Organic, Compound |

| Double Roller Granulator | 1-4 | 3-10 | <15% | Organic, Compound |

| New Type Organic Fertilizer Granulator | 1-8 | 2-5 | 20%-40% | Organic |

| Flat Die Pellet Mill | 1-2.5 | 1-10 | <15% | Organic |

| Drum Churing Granulator | 5-8 | 2-5 | 20%-40% | Organic Compound |

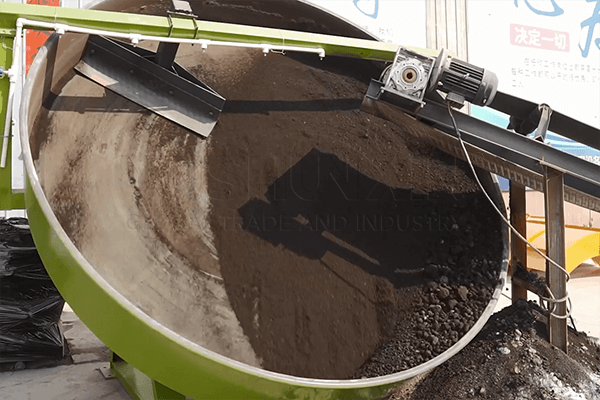

Top 1: Pan pelletizer (disc granulator) for small scale fertilizer granulation

For small scale fertilizer granule making, many fertilizer manufacturers prefer to buy a disc pelletizer.

- For one thing, the machine is an easy-operation machine to make fertilizer granules. Only with the disc rotation and water adding, it can turn fertilizer powder into pellets within several minutes. Maximum capacity is 6 t/h.

- For another, the granulating rate of this type granulator can reach more than 93%. Both for organic fertilizer granulation and compound fertilizer pelleting.

- What’s more, it can fully meet your requirements for 1-8 mm fertilizer granules production. You can regulate the fertilizer pellets size freely by controlling material moisture and plan slop angle. Less water, smaller size; much water, bigger size. Sharp slope, smaller size; slow slope, bigger granules.

Inquiry the disc fertilizer granulation system!

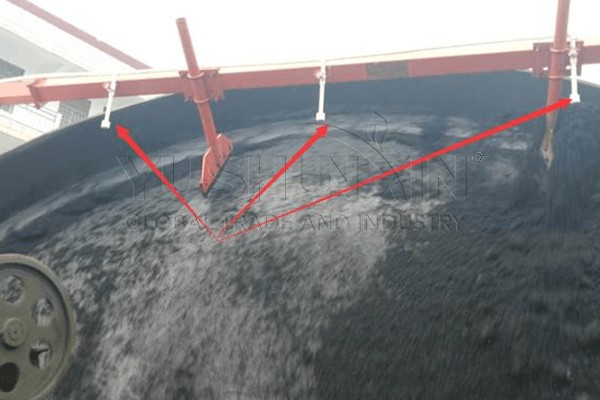

Top 2: Rotary drum granulator for large scale industrial fertilizer granulation plant

Drum granulator is one of the key equipment in large scale industrial fertilizer granulation plant setup.

- On the one hand, with rotary drum and water spray design, the machine can fully meed your needs to make fertilizer pellet between 1 t/h and 30 t/h. And the fertilizer granulation rate is over 90%.

- On the other hand, for longer time produce organic and compound fertilizer granules for you, we add the rubber lining and sticking prevention holes to it. They can reduce the fertilizer processing erosion to the equipment.

Of course, the machine is also suitable for both organic and chemical fertilizer pelleting projects.

Learn more about rotary fertilizer granulation!

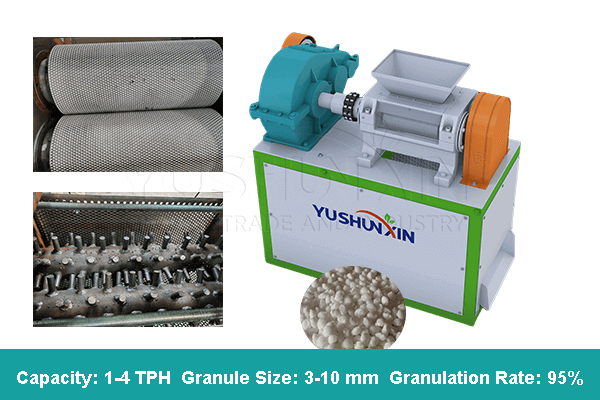

Top 3: Double roller extrusion granulator for faster fertilizer pellet production

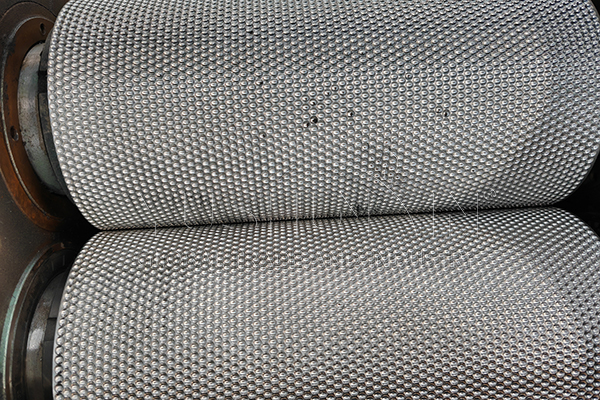

For faster organic and NPK fertilizer granulating, we especially design double roller extrusion granulator for sale.

- As the name suggests, the fertilizer granulator machine relies extrusion force between rollers to press fertilizer powder into granules. Once pressing, you can get high hardness granular fertilizer. At the same time, the granulation rate can reach 95%.

- According to your requirements for the shape of ball and socket on this granulator, the shape of roller sheet can be like pillow, semicircle, stick, pill, walnut, flat ball and square bar, etc.

What is the cost of the double roller granulation line?

Top 4: High granulating rate new type organic fertilizer granulation machine

But, if you prefer to produce fertilizer pellets with a higher granulation, we recommend you buy the new type organic fertilizer pellet machine in YUSHUNXIN.

- Besides makes use of liquid as binder, the fertilizer granulator machine adopts stirring teeth design to speed up fertilizer granulation.When the powder materials are sent in this granulator, stirring teeth begin rotating at high speed. Then under the action of high speed rotating mechanical force and resulting aerodynamic force, raw material will achieve the process of mixing, granulating, balling, densification and from into organic fertilizer granules and chemical fertilizer pellets quickly.

- At the same, the granulation rate can reach 97%. Additionally, it also has advantages of high hardness fertilizer pellets manufacturing and lower dust pollution.

Is there video of new type organic fertilizer pellet making?

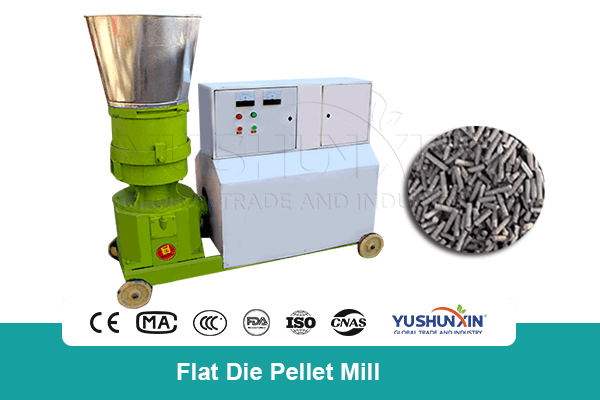

Top 5: Economical flat die pellet mill for sale

Moreover, we design flat die granulator for economical fertilizer pellet preparation.

- Fist, it has a economical price. With 1-2.5 t/h output, you only need to prepare $3,000-$6,000 for buy a flat die fertilizer pelletizer. At the same time, the machien has features of easy operation, less area occupation, etc.

- Then, the machine is also suitable for various material pellet making. Such as organic fertilizer pellet making, feed pellet production, biochar briquettes pressing, wood pellet manufacturing, etc.

Can flat die granulator process 5 t/h fertilizer?

Top 5: Two-in-one rotary drum churning granulator

Finally, for these who prefer to produce round ball fertilizer granules with a high granulation rate, you can buy a rotary drum churning granulator. As the name suggests, it combine the stirring teeth and rotary drum granulation methods. Therefore, the fertilizer granulator machine is beneficial for fertilizer granulation in aspects:

- Higher fertilizer granulation rate: Under the action of stirring teeth mechanical force and water cohesion, the fertilizer pellet making rate can reach 97%.

- While, with help of drum rotating, the granulated fertilizer pellets have a more rounded shape and smooth surface. So, it has a higher value and help you make more profits.

Get your customized fertilizer pellet making plan!

What are the prices of the fertilizer pellet machines?

When buy a fertilizer granule making machine, whether it is for organic fertilizer manufacturing or compound fertilizer preparation, we must focus on the price. As a source factory for fertilizer granulators, YUSHUNXIN can offer you a favourable price. In general, the prices of the above 6 types of fertilizer pelletizers are as follows:

- Disc pelletizer price : $3,500-$15,000

- Rotary drum granulator cost: $8,000-$90,000

- Double roller extrusion machine price: $4,000-$13,000

- New type organic fertilizer granulator cost:$5,200-$55,000

- Plat die pellet mill price: $3,000-$6,000

- Rotary drum churning granulator cost: $20,000-$30,000

The above fertilizer granulator prices are for reference. Because it will fluctuate with equipment design details, material use, time, exchange rate, etc. You can contact us now for price quote for fertilizer granulation machines.

How to make fertilizer granules more rounded?

Among the above fertilizer granulation machines, the roller press granulator, flat die pellet mill will produce flat ball and column shape fertilizer pellets for you. Is there machine to make fertilizer particles more rounded and uniform size? Here, fertilizer polishing machine is designed for you. With the help of this machine, the granulation rate rate will be higher as well as no returning materials created. So, it makes your organic and compound fertilizer granulation process more effectively.

What is the moisture content of raw materials before fertilizer granulating?

The moisture content of raw materials before fertilizer granulation process is a critical factor that significantly influences the efficiency and quality of the final fertilizer granules. If the moisture content is too low , the powdery materials may not bind together effectively during the granulation process, resulting in weak, brittle granules that can easily break apart. Conversely, if the moisture content is too high, the materials can become overly sticky and form large, uneven clumps, which can clog the fertilizer granulator machine and lead to poor granulation quality. Then, what is the best moisture for fertilizer granule making? For this, you need to consider the granulation method you adopts is wet or dry.

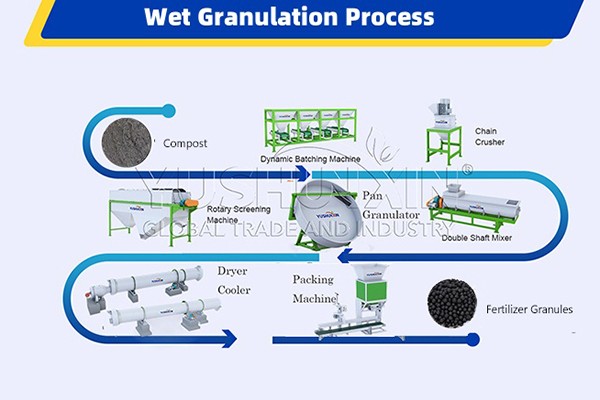

fertilizer wet granulation moisture

When you buy a wet granulation machine for organic or compound fertilizer pellet making, you need to adjust the material moisture to 20%-40% before granulating. Including pan pelletizer, rotary drum granulator and new type organic fertilizer granulator.

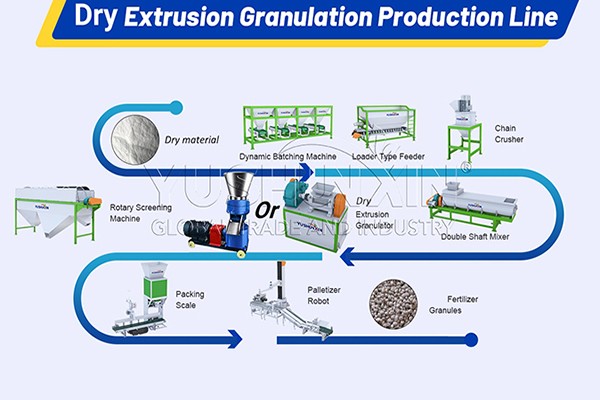

dry granulation equipment feeding material water content

But, for dry granulation equipment working, it requires feed material water content lower than 20%. Because it mainly makes use of roller extrusion force to granulate organic and compound fertilizer powder.

Here, YUSHUNXIN can offer fertilizer dewatering machine and dryer for moisture reduction and granulators with spray device for water adding.

Get your own fertilizer granulation plan now!

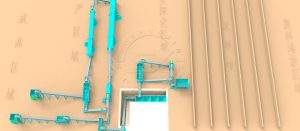

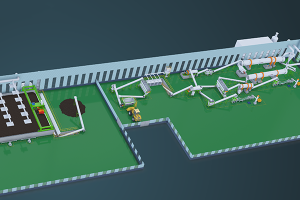

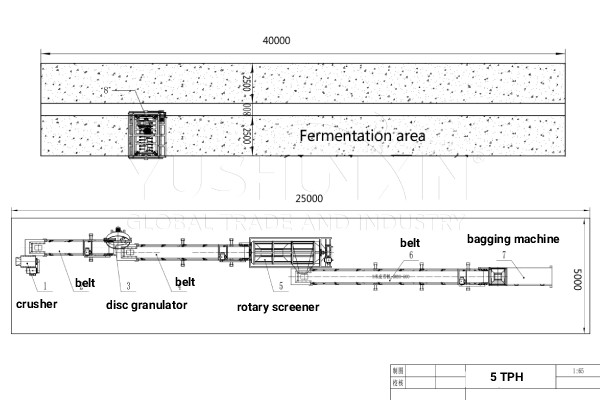

Can you offer complete fertilizer granulation line?

Of course. Generally, a complete fertilizer granulation line mainly includes material batching machine, crusher, mixer, granulating, screener, dryer, cooler, coater, and packaging equipment. Each part is designed for stable operation and efficient fertilizer production. If you plan to start or upgrade your fertilizer manufacturing project, we can provide a complete fertilizer granulation line with customized design according to your raw materials, capacity, and budget, etc. For example,

Organic and compound fertilizer granulation lines

When you process fertilizer pellets with organic waste, like chicken manure, cow dung, biogas residue or compost , we will add dewatering machine and composting turners for you.

Or produce compound fertilizers of NPK, SSP, or zeolite granules, there is no need of equipment of composting and dewatering.

Small and large scale granular fertilizer plants setup

Then, as mentioned above, for a small scale fertilizer granulation plant setup, both disc granulation line and roller press pelleting system are ideal choice.

When it comes to large scale granular fertilizer making, the rotary drum granulation line is recommended. In addition, there also customized disc, roller press granulation plans for large scale operation.

Solutions for wet and dry fertilizer granulation technologies

Besides, in terms of granulation method, there are also customized granulated fertilizer manufacturing solutions. For wet granulation, which is processed with 20%–40% moisture, you can choose rotary drum granule making plan or pan pelletizing systems.

Meanwhile, for dry granulation, the water content of material should be below 20%, the double roller extrusion process is here for you.

If you have any other requirements for your fertilizer pellet making line setup, welcome to contact us for customization.

Get your own fertilizer granulation plan now!

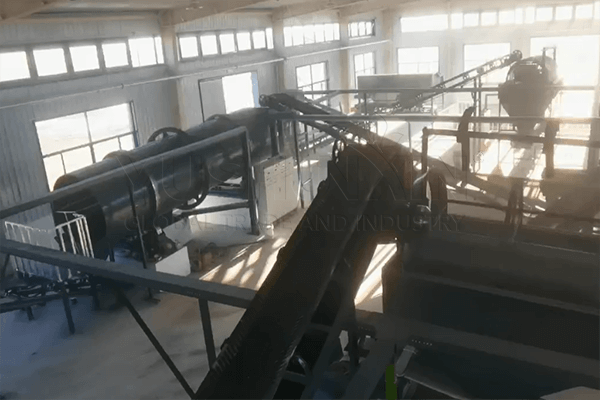

Finished projects of fertilizer granule production all the world

Provided you need finished fertilizer granule making plants with YUSHUNXIN machines, there are some cases for your reference. For example, cow dung granulation line in Ecuador, $50,000 biofertilizer granulation line in Vietnam, SPP pellets making in Egypt, ice melt granules making in Korea, etc. Our fertilizer granulator machines have sold to all the world and earn good feedback.

In addition, combine with crusher, mixer, screener, dryer, coator, packing machine, you can setup a fertilizer granulation line for better fertilizer pellet making. Welcome to contact us now!