In general, if you want to make organic fertilizer from cow dung, there are various business plans for you. Including solutions to dispose of cow manure into organic fertilizer of powder, granules and liquid. Additionally, YUSHUNXIN especially designs customized cow dung fertilizer project design according to your requirements of final fertilizer types, budget, capacity, etc. You must can find the most suitable plan for your cow poop fertilizer production.

Main Parameters

- Capacity: 1-20 t/h

- Types: powder & granule & liquid

- Area: 800-10,000 ㎡

- Cost: $30,000-$550,000

- Equipment material: Q235 Carbon steel or stainless steel

- Voltage:220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: cow manure waste management, organic fertilizer production

How to make cow manure into quality organic fertilizer?

How to process cow manure into powdery organic fertilizer?

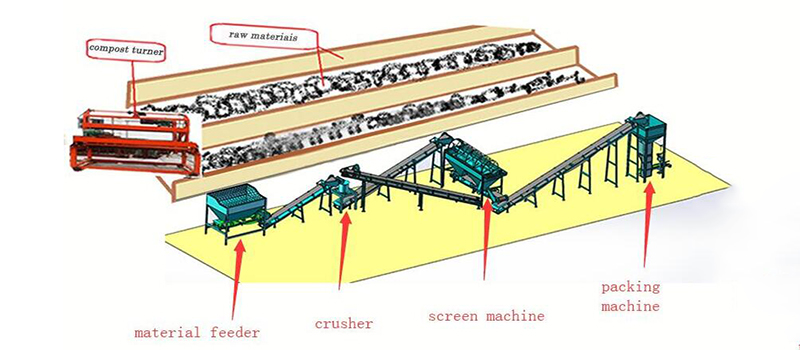

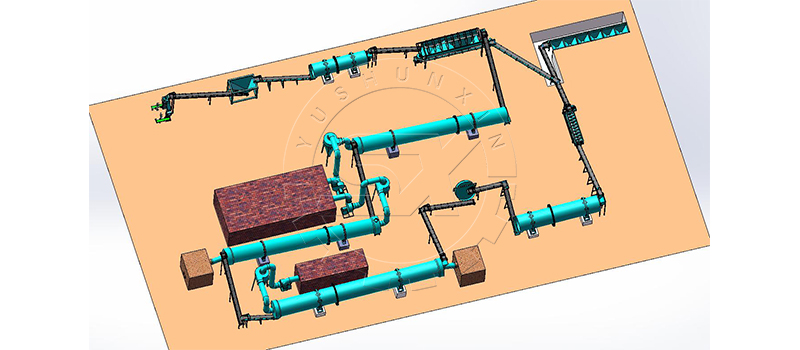

Are you finding a simple and low cost cow dung organic fertilizer making process? One of the best solutions is powdered organic fertilizer production line. Only need 6 steps, it can produce quality organic fertilizer with cow manure. Cattle waste recycling, moisture adjustment, composting, crushing, screening and packaging. Because the simple process, you can greatly reduce the costs of cattle manure fertilizer equipment buying, factory rent and fuel. But, it also can fully meet your requirements of 1-20 tons of cow dung disposal per hour. The complete steps are as follows:

Inquiry the powder cow manure fertilizer production line!

How to make cow manure into organic fertilizer granules?

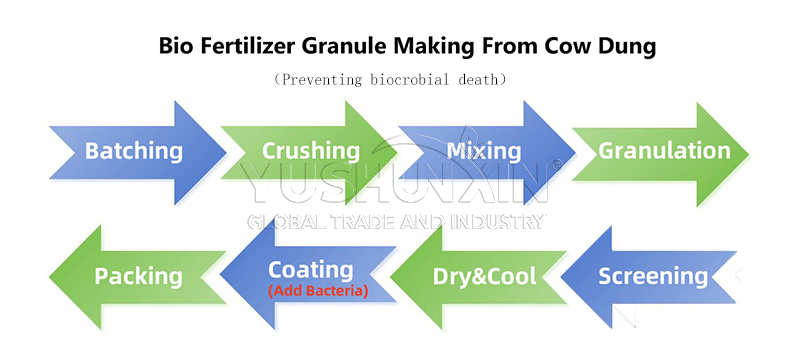

If you want to further improve the quality of your cow dung fertilizer, you can choose to process it into pellets. In this way, your cattle waste fertilizer is easier to transport, store and use. Organic fertilizer granulation line usually is based in the powder fertilizer making sysem. So besides the above steps, you also need processes as follows:

Can we make bio fertilizer from cow dung?

Of course. The bio fertilizer making line is designed on the basis of cow dung organic fertilizer production line. Only need to add suitable functional bacteria timely. For this, we can provide you with professional cow dung bio fertilizer manufacturing line.

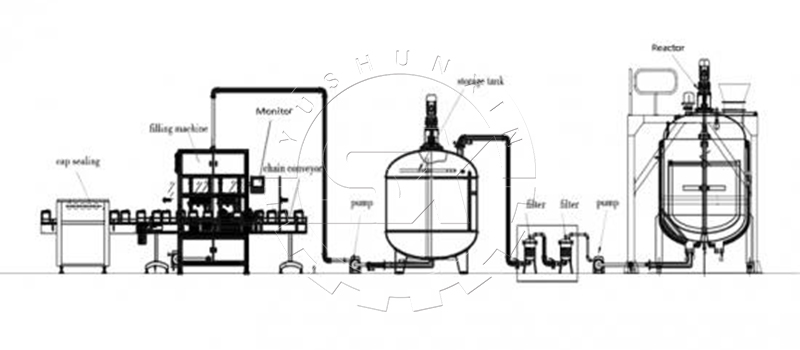

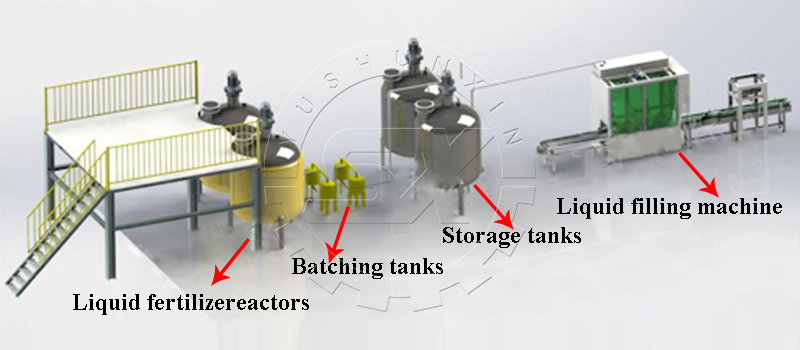

Can we make liquid manure fertilizer from cow dung?

We can make organic fertilizer powder and granules from solid cow manure. But, how to dispose of liquid cow manure waste? Can we make cow manure slurry into liquid manure fertilizer? Of course. Generally, it contains 6 steps: liquid deparation, small solid filtering, UV disinfection, adding other materials, fermentation, liquid filling.

Contact us for customized plan for making liquid fertilizer from cow manure now!

Why composting is necessary to convert cow dung into organic fertilizer?

If you want to process cow dung into organic fertilizer, composting is the first step. Without composting, you cannot use cow manure directly as fertilizer for the plants. Why? there are two reasons:

Fresh cow dung contains many harmful substances

Usually, fresh cow dung in the farm is the source of many kinds of bacterial pathogens. And it contains parasite eggs and disease-causing microbes. If you leave cattle manure alone on the farm, it will generate malodor to produce effects on breeding communities. In addition, if you use it directly as fertilizer for the plants. The fresh cow manure will compost naturally and produce lots of heat to burn the roots and seedlings. So, fresh cow manure is not truly organic fertilizer products.

Composting makes cattle waste harmless

But the composted cow dung is different. During the process of cow manure composting, the high heat will be generated and kill harmful bacteria, pest eggs and grass weeds. Moreover, after composting, the cattle droppings no longer stink and generate heat during use. So you don’t worry that it will burn plant roots. But it takes a long time to make the cow dung to decompose and ferment naturally, about 2-3 months. So you need some fertilizer composting machines to shorten this time. Only about 20 days.

Get your cow manure compost machine immediately!

What is the cow dung fertilizer machine price for power and granule?

First, the cost of making commericial fertilizer from cow dung is related to the is it powder or granule making?

In general, because of simple process, the quote of a complete powder cow manure fertilizer making line equipment is between $35,000 and $90,000. At the same time, you need to prepare $100,000-$550,000 for cow dung fertilizer machine for granule making.

Also, it is affcted by your cow manure fertilizer plant scale. The large the capacity, the higher the cost; the small the scale, the lower the investment.

As a source factory for cow dung fertilizer machine, YUSHUNXIN can offer you a facourable price. In addition, we receive various fertilizer machine payment method, including DDP. So, no need to worry about the customs clearance of your fertilizer equipment. After placing the order and paying, just wait for the cow manure fertilizer equipment to arrive.

Get the precise quote of cow dung fertilizer machine you need now!

How to make granular organic fertilizers from 200 cow’s dung in your own farm economical?

In general, a cow will generate 30 kg of manure waste a day. So if you have a 200 cows farm, there is 6 tons of cattle manure need to dispose of per day. For this, if you want to manage cow dung in a economical way, you can only buy several key equipment for make organic fertilizer granules with cow manure.

Cow dung dewatering machine

The dewatering machine is an indispensable machine in the cow manure fertilizer production process. Our cow dung dewatering machine can separate fresh cow manure into liquid and solid effectively. After separated by this machine, the water content of the cow manure is 30%. Besides, the slag yield and water content of your raw materials can be adjusted. Therefore, you can dehydrate the material according to the actual working requirements. For 6 t/h cow manure disposal, you only need a 1 t/h screw type dehydrator. It is a multi-functional dehydrator which also can process chicken manure, duck droppings, cow dung, wine residue etc.

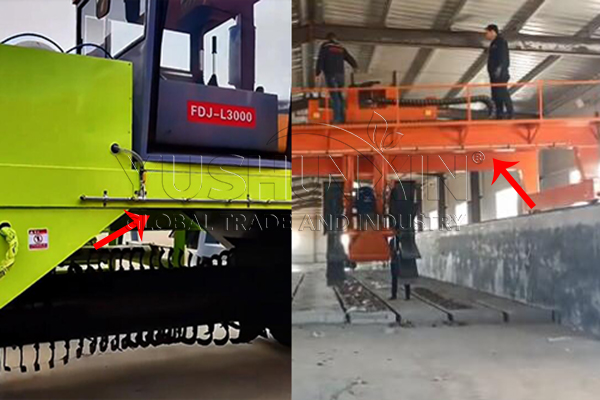

Compost machine for cow manure waste

Composting is the key process to make cow dung fertilizer. In order to improve work efficiency, a professional compost turner is needed in this time. For 6 tons/day small scale fermentation of cow dung, the most economical choice is groove type compost machine. It mainly adopts the aerobic fermentation technology to decompose the organic matter in cow manure wastes. This type of cow dung fertilizer machine can turn the compost piles regularly to let more oxygen come into the core of the piles. In this way, it speeds up the compost making process greatly and eliminate the appearance of anaerobic environment.

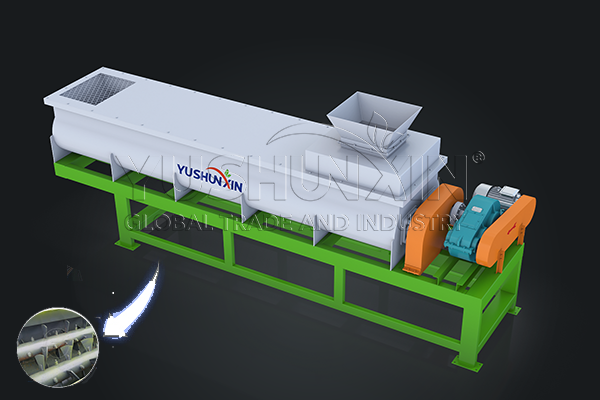

Cow manure mixing machine

Generally speaking, during cow manure fertilizer making, we will use various materials. Especially when you want to add some biological species for better manure compost products. Or when you want to enhance the content of a certain element of your final fertilizer. At that time, double shaft mixing machine can help you a lot in both small and large scale cow manure fertilizer granulation. With two blending shafts, it can mix the cow manure compost with them evenly to to meet your requirements. This can prevent your cow dung organic fertilizer from nutrient imbalance.

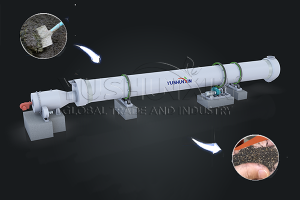

Cattle manure granulating equipment

Cattle manure pellet equipment is a kind of cow dung fertilizer machine used in organic fertilizer granulation process. This equipment can help you make fertilizer granules for salable organic fertilizer products. And for this economical cow dung fertilizer pellets making project, disc pellet machine is an excellent choice for you. Besides, you can use an organic fertilizer polishing machine to make your cow dung pellets looks more beautiful. If you have any questions about them, just feel free to contact us.

The simpler process of cow dung fertilizer production, the less fertilizer equipment is needed. This not only save you cost on organic fertilizer production equipment, but also save your farm space. Welcome to send us your requirements for cow dung fertilizer machines, we will deisgn customized business plan for you

Contact us for your own cow manure fertilizer making machines!

Why can cow manure be used as fertilizer?

Cow dung is a derived wastes produced by cattle farming. It has smelly odor, pathogens, pest eggs, grass seeds, etc. So, leaving it alone will cause a serious environemental pollution. Currently, the most common and valuable processing method is to turn cow dung and manure into salable organic fertilizer.

According to the data, daily cow dung contains crude protein 10% – 20%, crude fat 1%–3%, nitrogen free extract 20%–30%, crude fiber 15%–30%. They can provide high levels of organic matter and rich nutrient content, including about nitrogen, phosphorous and potassium as well as many other essential nutrients.Once raw cow dung composted by professional cow dung fertilizer machine, it can provide rich nutrients to the crops and plants without harms. This also makes cow manure become a kind of popular and useful raw material of organic fertilizer production.

Are there any established cow dung organic fertilizer plants?

Of course. We have help many customers to setup cow manure fertilizer production plant successfully. For example, Manure Management System For 2000 Cattle In Mexico, cow dung composting in Kenya, 5t/h Cow Dung Fertilizer Production Line In Indonesia, etc.

Where to buy the right machine for your cow dung manure making business plan?

After deciding the types of cow dung fertilizer processing machines you want to buy, you also need to pay attention to where to buy these machines? Here, SX fertilizer equipment factory is an ideal choice for you. Why? There are 3 reasons as follows:

SX can offer you all cattle waste fertilizer making equipment

SX is a leading fertilizer equipment manufacturing company from China. We can provide you with all equipment for a complete cow dung fertilizer making system. Whether you need a compost machine or pellet equipment, whether you want to buy equipment for small or large scale cattle manure organic fertilizer production.

SX can provide you with quality organic fertilizer machine at a favourable price

For one thing, SX has advanced technologies and many years of experience in fertilizer making machines manufacturing. So we can provide you with quality cow manure processing equipment. For another, SX is the source factory of fertilizer equipment and there is no extra charge in cow dung fertilizer machine sales. Therefore, you can purchase required equipment at a low cost.

SX can offer you considerate services

In addition, we will provide you with the best service to ensure that you can start your organic fertilizer production with cattle waste as soon as possible. Including all-round answer of fertilizer production, free project design, customized equipment service, installation guidance, etc.

Other common FAQ about cow dung fertilizer making

If you want to manufacture high quality organic fertilizer from cow dung. It is essential to keep a proper moisture content of manure. At 50%-60% is the best. There are some tips can help you adjust the moisture content of your materials.

How to increase the water content of dry cow manure?

If you use dried cow dung to make organic fertilizer, there are two choices for you to increase its moisture content. First, you can add some water directly during the composting process. Second, you can mix it with fresh cow waste to balance its moisture content.

How to remove excessive water from fresh cow dung?

If your raw material for composting is fresh cow dung, you need to adjust the water content before compost production operations. Because the water content of fresh cow dung is too high (generally up to 85%), which is not suitable for hot composting. So you’d better remove some moisture as appropriate. There are two methods for you to adjust the water content. The first one, you can add some accessory materials to absorb the excess water from fresh cow manure. For example, sawdust, straw, peanut hulls, grass ash carbon and so on. For the another one, you can use manure dewatering machine to remove the water quickly.

In general, you need to control the moisture content of the cow manure at about 60% before fermenting. When you hold them in the hand, you can feel they are wet. And when you release your hand, it cannot drip from the fingers.

In fact, cow dung is a good material to make organic fertilizer. Because it has rich nutrients, which are necessary for the growth of crops and plants. Such as organic matter, nitrogen, phosphorus, potassium, calcium, etc. And many people have realized the nutritional value of cow manure for organic fertilizer making. But they do not know how to make organic fertilizer from cow dung scientifically. Therefore, the nutritional value of cow manure has not been fully utilized and even the unpleasant phenomenon appeared. In this aspect, SX can provide you with professional fertilizer processing machines to help you turn cow dung into high quality organic fertilizer. If you need it, you can contact us.

1 thought on “How To Make Organic Fertilizer from Cow Dung”