New type organic fertilizer granulator, as the name suggests, is an equipment widely used in making organic materials into pellets. And because it turns fine powdery compost into granular organic fertilizer mainly by rotary mechanical agitation force of stirring teeth and the resulting aerodynamic force. Compared other organic fertilizer granulation equipment, it can fertilizer pellets with high stength and lower possibility of pulverization. At the same time, the machine has characteristics of 95% high granulation rate, various models of 1-8 TPH capacity, adjustable granules making of 2-5 mm, etc. In addition, for fertilizer granulation plant setup, YUSHUNXIN can offer you customized solutions and auxiliary equipment according to your capacity, budget, energy supply, etc. If you are interested in, welcome to contact us see them now.

Main Parameters

- Capacity: 1-8 t/h

- Granule Size: 2-5 mm

- Granulation rate: over 95%

- Feeding material moisture: 20-40%

- Feeding material size: 50 meshes

- Equipment Material: Carbon steel Q235, Mn steel, etc

- Application: animal manure, biogas residue, humus, muschroom waste, sludge, etc

When is the best opportunity to use a new type organic fertilizer granulator?

One tip of selecting a suitable granulation machine for your fertilizer production plant is to do it according to your actual conditions. Then, is the new type organic fertilizer granulating machine suitable for you? If you want to produce organic fertilizer pellet of high strength, 2-5 mm, 95% granulation rate and in a small to medium scale.

Dispose of organic waste into fertilizer pellets

As the name suggests, the new type organic fertilizer pelletizer is designed for turning organic compost into granular fertilizer. Here, whether you plan to use chicken manure, cow dung, pig manure or mushroom residue as materials to make organic fertilizer pellets, this fertilizer pelletizing machine can fully meet your needs.

50,000 tons annual organic fertilizer plant setup

If you are looking for a granulator for small or medium organic fertilizer preparation, lower than 50,000 tons annual, we recommend you choose the stirring teeth pelletizer. Because the capacity of this equipment is 1-8 t/h. With 20 hours operation a day, it can granulate powder of 6,000-50,000 tons a year. And, we divide it into various models. There are SXJZ-600 for 1-1.5 t/h small scale, a SXJZ-1500 with an output of 6-8 t/h.

Main Technical Parameters of YUSHUNXIN New Type Organic Fertilizer Granulator:

| Model | SXJZ-600 | SXJZ-800 | SXJZ-1000 | SXJZ-1200 | SXJZ-1500 |

|---|---|---|---|---|---|

| Installation Angle (°) | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 |

| Capacity (t/h) | 1-1.5 | 1.5-2.5 | 2-4 | 4-6 | 6-8 |

| Total Power (kw) | 37 | 55 | 75 | 90 | 110 |

| Moisture of Feeding Material | 20%-40% | 20%-40% | 20%-40% | 20%-40% | 20%-40% |

| Size of Feeding Material (mesh) | 50 | 50 | 50 | 50 | 50 |

| Dimensions (mm) | 4100*1600*1150 | 4250*1850*1300 | 4700*2350*1600 | 4900*2550*1800 | 5500*2800*2000 |

Prepare fertilizer granules with high strength

Provided you want to produce fertilizer granules with high hardness, the new type organic fertilizer granulating equipment is also an ideal choice. For one thing, it adopts wet granulation method, which uses liquid as binder to enhance the adhesive force between the organic materials. So the finished fertilizer pellet has a higher density and strength. For another, it makes organic fertilizer particles by stirring teeth granulation method. Compared natural rotation granulation, this method will manufacture the organic fertilizer granule with a lower possibility of pulverization.

Over 95% rate of conversion from powder to pellets

A pelleting equipment with a high granulation rate usually means that it can help you reduce materials waste and time taking on organic fertilizer production. The granulating rate of YUSHUNXIN new type organic fertilizer granulator is 95% or higher. So using the same amount of raw material, it can produce more pellets in a short time than general pelletizers.

How does the new type granulation machine work to make granular organic fertilizer?

When you want to produce required fertilizer pellets, you need to clear the working principle of the new type organic fertilizer granulator. Then how does equipment work to convert organic waste compost to particles?

In fact, the commercial fertilizer granulation equipment mainly by the stirring shaft inside the new type granulating equipment, which has many stirring teeth on it. After material feeding, the stirring shaft will start rotating. And the stirring teeth will mix the organic fertilizer powder in the granulator. Then under the action of high speed rotary mechanical agitation force and the resulting aerodynamic force, the fine powder materials will continuously achieve the process of granulating, balling and densification in the stirring teeth pelletizer, so as to achieve the purpose of granulation. Then the produce organic fertilizer granules will be discharged by the outlet and transported to the next process.

This the reason why the equipment also known as stirring teeth fertilizer granulator.

What granulation method does stirring teeth pelletizer employ?

Besides the sirring teeth, the new type organic fertilizer granulator also speed up the fertilizer pellets making by liquid cohesion. This commonly called wet granulation method. When the material moisture is at 20%-40%, the powder materials will form into fertilizer granules faster. Moreover, the finished fertilizer pellets will have a higher density and not easy to pulverize. Therefore, you can get better experience on fertilizer transport and storage, if you choose to make granular organic fertilizer with new type pellet production machine.

Learn more about the stirring teeth fertilizer granulator!

Tip: Also, there are fertilizer pellet equipment that adopts dry granulation method. Which granulates fertilizer powder nearly no liquid involved.

How to regulate the fertilizer pellets size during stirring teeth granulation?

If you want to know whether this new type organic fertilizer suitable for you, a important consideration is final fertilizer pellets. Is it produced with required shape and size? Usually, the stirring tooth granulator will process granular fertilizer with 0.7 spherical degree and 2-5 mm diameters.Then how to change the size of the pellet during stirring teeth granulation of powder? You can consider it from following 3 aspects:

Material moisture content

Because the new type granulation machine adopts wet granulation method, the water content control is important in organic fertilizer pellet size adjustment. And in general, less water, smaller size, much water bigger size.

Teeth spindle speed

In addition, considering it from mechanical aspect, you need to focus on the rotating speed of stirring shaft. Generally speaking, higher rotational speed, smaller particle, and vice versa.

Mixture quality

Finally, the organic mixture also plays an important role in the size regulation of final organic fertilizer granule size. The lower the mixing volume, the smaller the particle. Higher mixing volume, bigger particle.

How to control fertilizer granulation moisture during stirring teeth pellet making?

As mentioned above, the stirring teeth fertilizer pelletizer adopts wet granulation method. At the same time, moisture control plays an important role in fertilizer granules formation with required size. Then, how to control the moisture for new type organic fertilizer granulation?

It needs to finish the moisture adjustment before feed in the powder granulation machine. Because of stirring steeh design, the machine can not equipped with liquid spray device inside. For this, it is advisable to use a double shaft mixer. Which has professional spray system for precise liquid adding while mixing it with powder materials evenly. For most organic fertilizers granulation, you need to adjust the material moisture to 20%-40% in stirring teeth fertilizer granulation line.

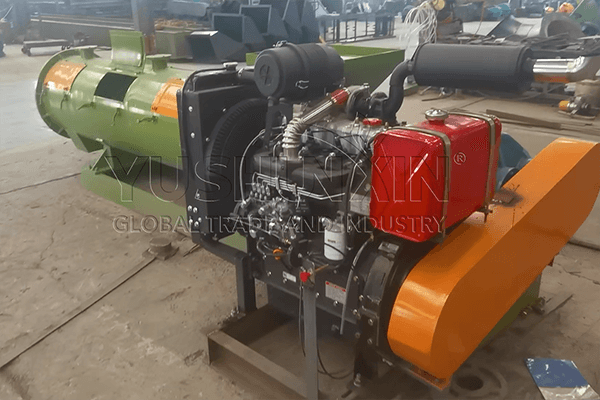

Is there new type organic fertilizer granulator with diesel engine?

of course. As a professional fertilizer equipment manufacturer, YUSHUNXIN can offer you customized new type organic fertilizer granulation machine with diesel engine.

- It is useful if you start fertilizer pellet making in areas without reliable electricity, remote farms, or places with high power costs.

- This feature also adds mobility of granular fertilizer production, allowing the equipment to be used in various locations without being tethered to a fixed power source.

- At the same time, the industrial fertilizer pelletizer also come with advanced designs to ensure fuel efficiency and reduced emissions, complying with modern environmental standards.

In addition, if you need a stand-by-generator for your stirring teeth granulation line operation, there are diesel generators of 100 kw-1000 kw for your choice.

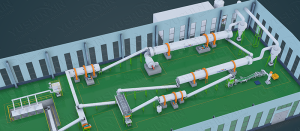

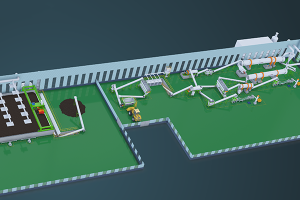

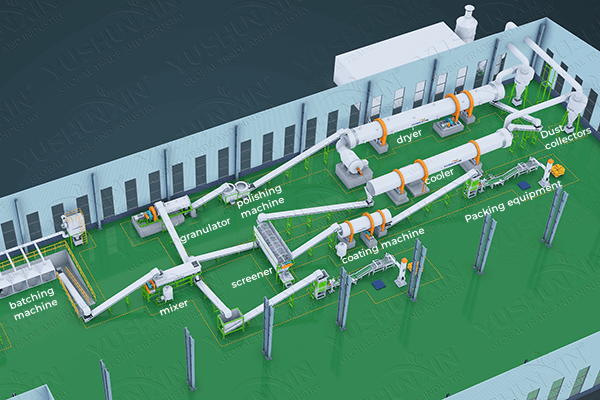

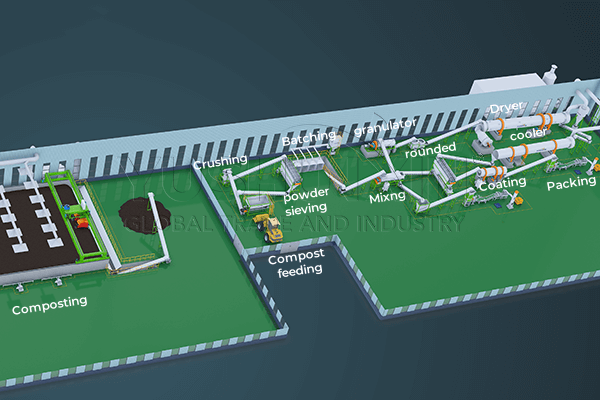

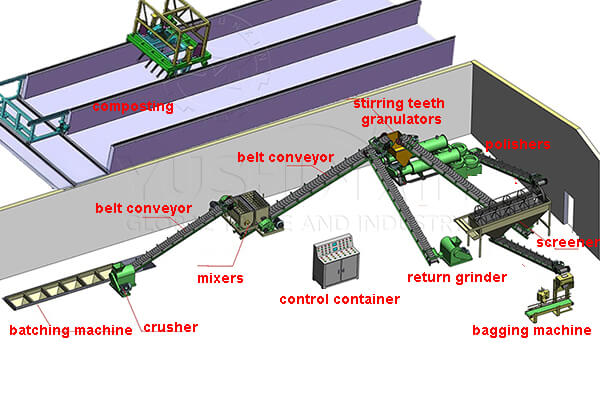

How to build organic fertilizer granulation line with the new type granulator?

For investors or farm owners planning to set up a large-scale organic fertilizer granulation plant, choosing the right configuration is the key to efficient and continuous production.

Commonly, for the stirring tooth granulation, a complete granular organic fertilizer making line built with 8 essential units. Including batching machine → crusher → mixer → new type organic fertilizer granulator → screener → dryer and cooler → coating machine → packaging system. Each machine plays a vital role in ensuring stable operation and consistent granule quality. For instance, the batching machine ensures precise raw material proportions, while the crusher and mixer help prepare uniform feed material before granulation.

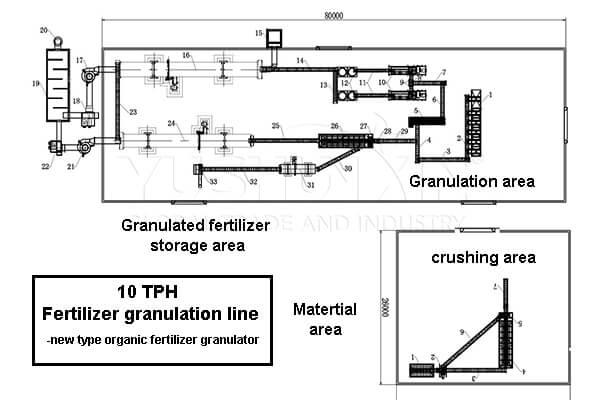

Can we setup a 10 TPH organic fertilizer granulation plant with the stirring tooth pelletizer?

As mentioned above, the maximum capacity of a new type organic fertilizer pelletizer is 6-8 TPH. So, for establishing a 10 TPH fertilizer granulation plant, you need to buy 2 sets of SXJZ-1200 pellet machines. Here, YUSHUNXIN will offer you reasonable design, which make the whole system work well.

Can you offer some finished fertilizer granulation projects for reference?

Of course. As a professional fertilizer granulation equipment manufacturer, we have supplied quality equipment for multiple organic fertilizer pellet production projects worldwide. Here are some successful cases for your reference.

Organic fertilizer pellets making from biogas residue humus in Italy

The Italy customer wanted to use biogas residue humus as raw material to produce organic fertilizer pellets. For 50% moisture material feeding and 6 TPH particles output, a SXJZ-1200 new type organic fertilizer granulation system is an ideal choice. Wet granulation using and high granulation rate of 95%.

Organic biomass manure compost granulator to Greece

In addition, there was also the customer from Greece, who planned to upgrade the organic fertilizer making line. Further process composted biomass and manure mixture into fertilizer pellets. For 2–2.5 T/H organic pellets production with uniform size and high-strength granules, the SXJZ-1000 stirring teeth granulator is advisable.

Raw manure waste to granular fertilizer projects

Moreover, for setting up an granular fertilizer making system for farm manure waste management, there are also established plants for your reference. Such as solution for Pig Farm Waste Disposal In Bulgaria, Chicken Manure Fertilizer Granulation Line For U.S. Customer, etc.

Come to get your own fertilizer manufacturing solution now!

Where to buy the organic fertilizer granulation equipment?

If you’re looking for high-quality organic fertilizer granulation equipment, YUSHUNXIN is a top choice.

Quality stirring teeth granulator offer

With over 20 years of experience in the industry, YUSHUNXIN manufactures advanced, reliable machinery that meets international standards.

Buy the fertilizer pellet machine at an economical price

They offer economical prices by directly sourcing from the factory, ensuring affordability without compromising quality.

Global distribution offices

Additionally, YUSHUNXIN has a strong global distribution network, with offices in countries such as Indonesia, Algeria, Russia, the United States, and Uzbekistan, making it easy to access their products worldwide.

Choose YUSHUNXIN for your organic fertilizer production needs and enjoy top-notch performance and value. Additionally, there are also large rotary drum granulator, dry extrusion pellet machine, economical disc pelletizer for you chocie.