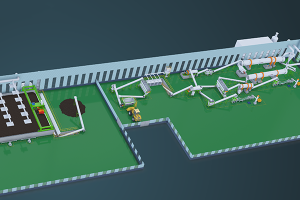

On 5th January 2025, a customer from Ethiopia inquired about how to dispose of cow manure waste into fertilizer? Considering local market demand and ROI, he finally choose to buy a system to make cow dung liquid fertilizer. The following are the specific details of communication in this case:

Project Overview

- Country: Ethiopia

- Capacity: 1t /h

- Material: cow dung

- Rquirement: Liquid fertilizer making

- Cost: $75,640 USD

Can NPK be added during cow dung liquid fertilizer production?

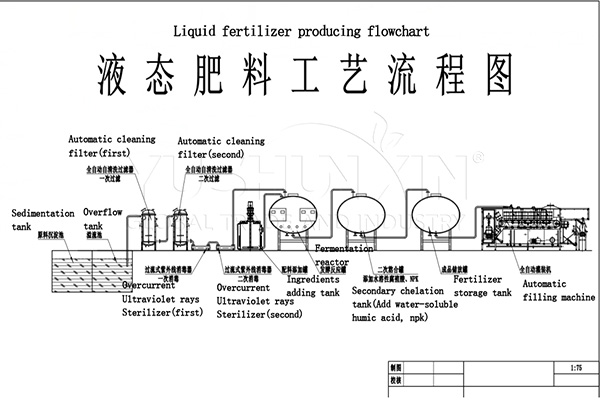

In order to produce cow dung liquid fertilizer with richer nutrients, the Ethiopian client wanted to add powdered NPK. Is this easy to achieve? In general, the process of organic liquid fertilizer production contains 6 steps. Liquid manure separation, impurities filtering, UV disinfection, auxiliary batching, liquid fermentation, storage and filling. Here, material batching step is an ideal choice to add NPK material in cow dung liquid fertilizer. And, it need different machines according to the material is powder or liquid.

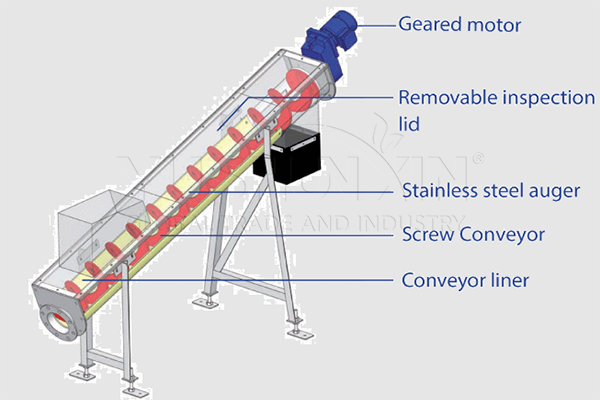

Screw feeder for adding powdered NPK to make cow dung liquid fertilizer

To add NPK powder to the cow manure liquid fertilizer making, it is advisable to use a screw feeder system. You can manually add the powdered NPK to the screw feeder, which will precisely feed the powdered NPK into the liquid reactor. Then the liquid chelating tank will mix the raw materials evenly with the cow dung liquid and ensuring that the nutrients are properly integrated into the final liquid fertilizer.

Professional batching tank for liquid material adding to fertilizer making

On the other hand, we also provide batching tank for liquid NPK material feeding. It can not only transport liquid auxiliary material to liquid reactor precisely, but also mix inside liquid to prevent sedimentation and nutrient stratification.

Can the temperature be adjusted for make cow dung liquid fertilizer?

In addition, for liquid fermentation tank, the customer from Ethiopia inquired about temperature adjustment. Because he wanted to keep temperature of the cow dung liquid fertilizer fermentation to 80°C. Which can ensure proper microbial activity and accelerating the fermentation process of liquid cow manure material.

Of course. To regulate the temperature, YUSHUNXIN especially design liquid cow dung fermentation tank with an electric control cabinet. This allows you to set and maintain the liquid fertilizer temperature precisely according to your needs.

How to monitor the liquid left in the storage tank?

Monitoring the amount of liquid fertilizer left in the storage tank is crucial for managing production of liquid cow dung fertilizer.

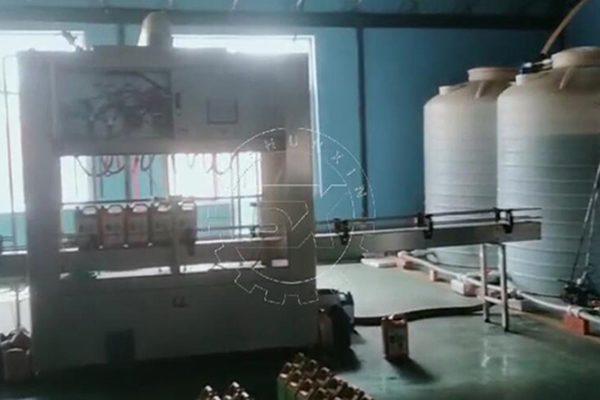

For this, you can choose to buy storage tanks with white appearance for the cow manure liquid fertilizer plant. In this way, you can easily see the level of liquid remaining in the tank. This is greatly beneficial for plan for refilling or transporting the liquid fertilizer as needed.

What Is the Price of the Cow Dung Liquid Fertilizer Production System in Ethiopia?

For setting up such a cow dung liquid fertilizer production line in Ethiopia, the CIF (Cost, Insurance, and Freight) price is approximately $75,640 USD. Here, you can make an initial payment of 20%-50% of the total cost. The left, you can pay us after cow dung liquid fertilizer machines manufactured and ready to delivery.

The above are details about our communication about how to make cow dung liquid fertilizer in Ethiopia. In addition, for cow manure disposal, we also can offer you powder fertilizer making line, cow manure granulation plan, etc. Welcome to contact us to get the solutions now!