Are you find the environmental way to dispose of organic waste? Including animal manure, straw, maize stocks, sugarcane residues, wine waste, etc. For this, making organic fertilizer is an ideal choice. Whether you plan to make powder or granular organic fertilizer, you must complete the composting of organic waste – the harmless process. Because during composting, all harmful bacteria, pest eggs and grass seeds will be killed thoroughly. In this way, you can use organic litter as fertilizer without any harm. Here, YUSHUNXIN can provide you with various compost fertilizer making machines to help you decompose organic waste quickly. You can choose the most suitable one according to your needs.

Main Parameters

- [Capacity] 1-20 t/h

- [Composting Time] 15-20 days

- [Material Moisture] 50%-60%

- [Composted Moisture] 30%-40%

- [Application] Animal manure, farm waste, biogas residue, mushroom waste, sugar factory waste, sluge, etc

How to compost organic fertilizer quickly?

What is the process of compost fertilizer making?

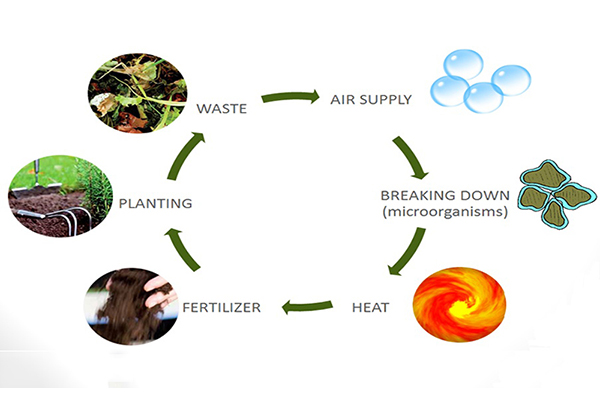

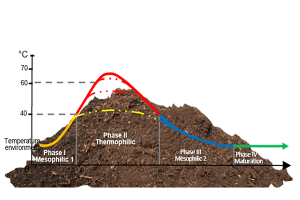

In general, a complete compost fertilizer production process can be divided into three parts. Pre-composting preparation, composting period and further processing. During pre-compost preparation, you need to focus on the moisture control and material size. Doing them well can create conditions for better aerobic fermentation and shorten the entire production cycle. During composting, professional composting machines will work to help you kill the harmful bacteria, pest eggs and grass seeds in organic material. So it is no longer harmful for crop growth, if using it directly as fertilizer. Then if you compost organic waste for commercial purposes and want to improve your compost competitiveness, you can further process it into organic fertilizer pellets.

What can you do for better compost fertilizer making in pre-composting preparation?

In the pre-composting preparation process, here are two things you can do to create a better environment for organic fertilizer fermentation.

Create a suitable humidity condition for better composting

Generally speaking, the most suitable material moisture content for composting fertilizer making is 45%- 65%. However, the main materials of compost fertilizer production usually have a high water content. Which can reach 70%-80%, and even 90%. Such as cow dung, chicken manure, sludge, etc. Here, SX can offer you professional dewatering machine, which can help you remove excessive water from manure quickly and easily. Using this machine, you can reduce the water content of compost to 30%-40%. Then, after a preliminary processing process, you can use fertilizer compost making machine to start aerobic fermentation.

Enlarge the contact area of compost pile with oxygen

In compost fertilizer manufacturing, sufficient oxygen supply is an item you must focus on. Because this is the reason why microorganisms in organic waste have enough energy to decompose organic matter and generate enough heat to kill the harmful substances in compost piles. For this, it is an excellent choice to enlarge the contact area of compost with oxygen. Here, crushing machine can help you a lot. It can grind big caking and agglomerate into fine powder. In this way, the compost materials can fully contact with oxygen and make better fermentation.

Which composting machines is suitable for your organic fertilizer plant?

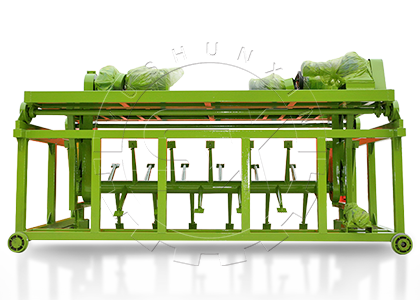

For aerobic fermentation process, the key equipment is the compost fertilizer making machine. As a professional fertilizer equipment supplier, SEEC has different kinds of compost machines for your to choose: trench compost turning facility, windrow composting equipment and in-vessel fermentation tank, etc. Using a compost facilities in the fertilizer making process is a mechanical way to speed up the fermentation process. It will turn over materials to increase oxygen supply and the porosity of the compost piles.

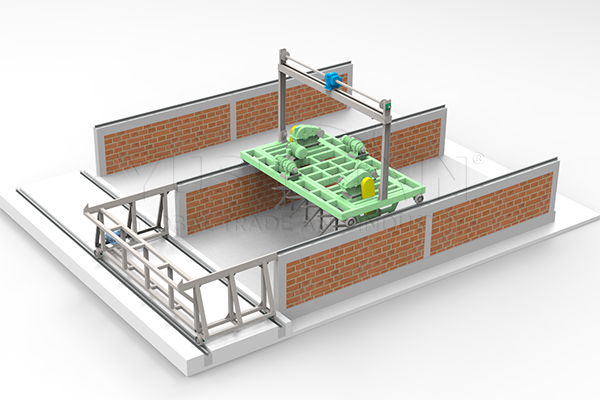

Trench compost turning facility

Trench composting is widely used in organic waste disposal. As its name suggests, it usually stacks raw material in fermentation groove and uses trench type composting machine to turn it. So organic material can fully contact with oxygen and finish fermentation faster. Then what is the size of the fermentation groove? In general, this is determined by your compost scale and compost machine you plan to buy. You can fermentation trench with a width of 2-30 m and a depth of 1-3 m. Here, YUSHUNXIN can provide you with groove type compost turner, wheel type composter and chain plate type compost turning machine.

Windrow composting equipment

If you prefer to make compost on the ground and don’t want to build fermentation trench. You can choose to buy windrow compost turner for your organic fertilizer compost business. Windrow composting is to collect organic materials and pile them into windrows, whose sections are trapezoidal or triangular. Then when windrow compost machine passes over the piles, it will mix and turn material with stirring teeth at the bottom. This will transport oxygen in material and dissipate excessive heat, so you can make a better fermentation. In SX, there are two types of windrow composters for your choice. Crawler compost turning machine, moving type compost turner and tractor behind compost machine.

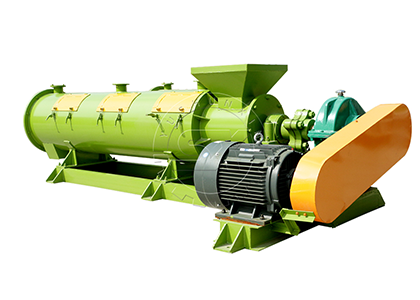

In-vessel composting machine

If you want to make compost fertilizer in a small space, SEEC recommend you to use the in-vessel composter in your plant. This kind of machine usually makes compost fertilizer in a full-closed environment. During this process, the mixing shaft in the machine will regularly blend the raw material to speed up aerobic fermentation. In addition, it is also equipped with oxygen supply device and gas waste collector. So it can help you make compost in a environmentally friendly manner and in a short time. And in order to meet your requirements, we especially design two kinds of in-vessel composters for your choice. Including vertical fermentation pot and horizontal fermentation tank.

How to further process compost into high quality organic fertilizer?

After the material is fermented, you can further process it into powdery compost fertilizer or granular organic fertilizer. If you want to process it into powdery compost fertilizer, you only need to separate qualified powder from waste by powder screener. Then, you can package them through SEEC automatic packaging equipment. However, if you want to get organic fertilizer granules products , we can fully meet your requirements. The granulation process is common in commercial fertilizer production process. When the powdery composted materials continuously finish the process of granulating and densification in fertilizer pellets making equipment, they will become granular fertilizer. Then, they need drying and cooling process for better store for commercial purpose. Then fertilizer screening machine will help you sort the high quality products which meet the production requirements. Finally you can package them to sell.

How to run a compost fertilizer business with low cost?

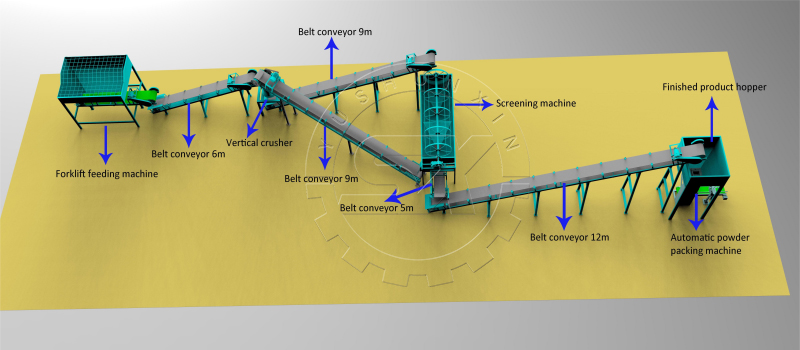

If your budget is limited, you can start with a small compost fertilizer business with low cost. For small scale compost fertilizer business, SEEC has designed a powder compost fertilizer production line for you. In this production line, the main compost fertilizer making machine includes the compost turner, SEEC new type vertical compost fertilizer crusher, rotary screen machine, belt conveyor and the compost fertilizer packaging equipment. This production line runs smoothly and has strong adaptability to the working field. If you have any special requirements for the facilities in this production line, welcome to contact us freely. We can communicate about the details of this project and provide customized service for you.

How to make compost manure fertilizer?

Manure is a kind of organic wastes for organic fertilizer making in agriculture. It is rich in organic matter, especially contains the important nutrients such as nitrogen, phosphorus, potassium and other trace elements. But, fresh manure can not be used directly as fertilizer. They will ferment naturally in the soil and produce high temperatures to kill the plant. What’s worse, they will bring lots of pathogens into the soil. These pathogens will contaminate the surface water and groundwater.

So, composting is a good way to kill the harmful substances in animal manure and make them into high quality manure fertilizer. Take cow manure composting for example, if you want to make compost manure fertilizer from cow dung, the first thing you need to do is dewater the feces. Then, you can mix the dehydrated animal manure with crop straw or wood chips to make compost manure fertilizer. For manure composting, SX recommend you the following facilities to get high quality composted manure.

What is needed to set up a compost fertilizer plant?

To set up a compost fertilizer plant, you need a professional compost fertilizer making machine supplier help you design for your compost fertilizer business. In addition, you need to consider the production costs to increase or decrease your project budget. Of course, your budget should include equipment acquisition cost, site cost, labor cost, energy consumption cost and the later maintenance cost. So, if you want to set up a compost fertilizer plant in your country, just tell us about your budget and business plan. Then, SX will tailor for you a with a satisfactory compost fertilizer business plan.