As a big agricultural country, India’s demand for fertilizers has been rising in past years. Therefore, many companies plan to invest in building a fertilizer production plant. On 25th July 2024, a customer from Jodhpur, Rajasthan inquired us about how to start 2 t/h organic fertilizer granulation line in India. After negotiation, he chose a disc granulation system for fertilizer making. The following are the specific details of the negotiation in this case:

Case Overview

- Capacity: 2 T/H

- Material: poultry dropping, cattle dung, pig dung, edible oil waste, sugar molasses, vegetable waste, maize husks, egg shells, rice bran, etc

- Final fertilizer: Organic fertilizer granules

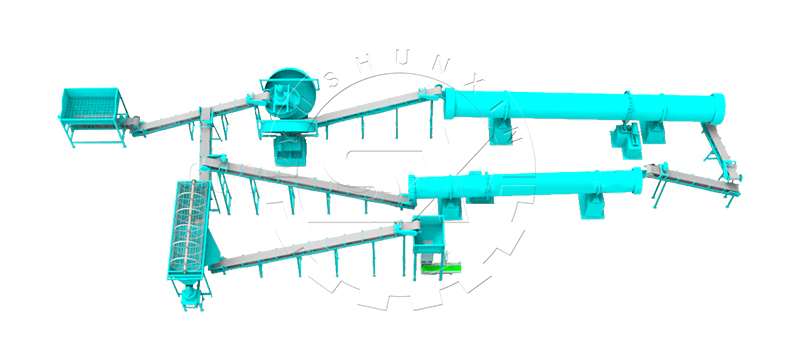

- Solution: SXYZ-2800 Disc granulation line

What kind of material can be used in organic fertilizer?

The raw materials from the customer including poultry dropping, cattle dung, pig dung, edible oil waste, sugar molasses, vegetable waste, maize husks, egg shells, rice bran, etc. They are all high-quality raw materials for organic fertilizer production. Among them, poultry dropping, cattle dung, pig dung, edible oil waste, sugar molasses and vegetable waste can be used as main materials. They can provide NPK nutrients to help crops grow up. Meanwhile, maize husks, egg shells and rice bran also are ideal materials for organic fertilizer manufacturing. For one thing, they can enrich the nutrients of your fertilizer. For another, they usually has a low moisture content, wihch can prevent excessive moisture affecting the finished fertilizer quality.

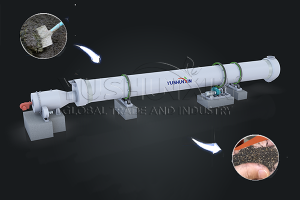

How to reduce the moisture content of the materials?

The wet content of the Indian customer’s materials is 50 %, and he want to know is it suitable for organic fertilizer pellets making. You can consider it from two aspect:

If the organic waste is composted

Provided you have not composted your organic fertilizer, this moisture content is just right. Because it is between 45% and 60%. During the fermentation process, a certain amount of heat is generated. This allows the water to evaporate into water vapour and remove it from the materials. After fermentation, the moisture content of the material will remain at 25-30%. It is suitable for manure granulation.

If you have finish organic fertilizer fermentation

But for starting granulation of organic fertilizer directly, it is not suitable. Because the advisable granulation moisture content is 20%-40%. For this situation, we can provide you with two solutions for moisture content reduction. First, as above mentationed, you can use low moisture materials to balance it, such as maize husks, egg shells and rice bran, etc. In addition, you can use a dewatering machine to separate solid and liquid materials, which can reduce the moisture content to 30%.

Start your fertilizer making business immediately!

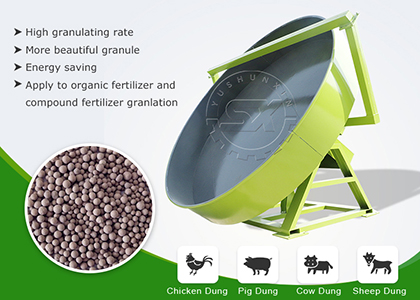

Which granulator is proper for your small scale organic fertilizer production?

The Indian customer wanted to prodcue granular organic fertilizer. For this, a suitable organic fertilizer granulator is necessary. Because the customer wants a pelletizer with a capacity of 2t/h and plans to produce 1mm granules. So we recommend the disc granulator to him.

On the one hand, It has a capacity of 1-6 t/h and has features of low cost. Therefore, it is an ideal choice for small scale organic fertilizer granulation. On the other hand, it can prepare organic fertilizer pellets with 1-8mm. And you can change the pellet size freely by adjusting the moisture content and regulating the pan slop angle.

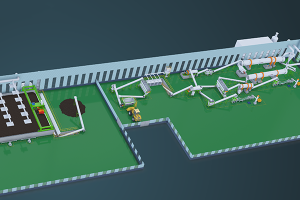

What other equipment I need to make my own organic fertilizer?

This customer wants to buy an organic fertilizer granulation line to process his materials. So we recommend other fertilizer equipment to help him improve granules quality. Before granulating, besides composter, crusher and mixer are important as well. Meanwhile, drying and cooling machines are also essential to prevent sticking. And the screener can help you distinguish qualified pellets from the unqualified. Finally you need to use coating and packaging equipment to make fertilizer easier to storage and transport. Anything else? Conveyor belt is necessary to link these fertilizer equipment.

The above are details about our communication with the customer for 2 t/h organic fertilizer granulation line in India. And we also provide you with other organic fertilizer production lines. If you have special requirements or want to know more, please contact us. As a professional fertilizer equipment manufacturer, SX will provide you with high quality fertilizer equipment you need.