For poultry manure management, composting is a necessary step to convert poultry manure into organic fertilizer. Especially with the development of organic agriculture, more and more people choose to use organic fertilizer rather than chemical fertilizer for their plants. If you do not know how to compost these valuable organic wastes effectively, YSHUNXIN can help you design your own poultry manure composting process. With our professional poultry manure composting equipment and scientific farm composting methods , you will get organic poultry compost quickly in your own farm. If you have any questions or requirements about our machine, just feel free to contact us!

Poultry Manure Compost Making

- Capacity: 1-20 t/h

- Composting Time: 10-20 days

- Types: 6 types for your choice

- Equipment material: Carbon Steel Q235, Alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: Composting chicken manure, duck waste, etc

What is the procedure of making compost from poultry manure?

If you want to make compost from poultry manure, there are lots of compostable raw materials. For example, chicken manure, duck manure, goose feces, turkey waste, pigeon and quail waste, etc. You can choose to collect poultry manure from local farms. However, if you have a poultry farm, it is easier to get enough compost materials. Generally speaking, the procedure of your poultry manure composting process can be divided into the following steps:

Collect manure and bedding

The first important thing you need to do is to collect the poultry litter and their bedding together to prepare enough materials for composting. What is the function of the bedding? Common bedding materials include wood shavings, sawdust, peanut hulls, shredded sugar cane, straw, etc. They are dry, absorbent, low-cost organic materials. So it can reduce the water content of poultry manure to make it more suitable for composting and organic fertilizer making. Moreover, these brown organic materials can provide enough carbon for your composting system. So, you can mix these organic wastes together to get carbon and nitrogen balance.

Regulating moisture content

Water is an important factor in the composting process. Proper moisture content can facilitate the poultry manure composting process. Here, SEEC recommends you to keep the moisture content at 50%-60%. In this condition, the activity of microorganisms is relatively active, and various substances dissolved in water also provide nutrients for microorganisms. Of course, if the material is too dry, you can add water to the pile. On the contrary, you can use our poultry manure dewatering machine to remove excess water.

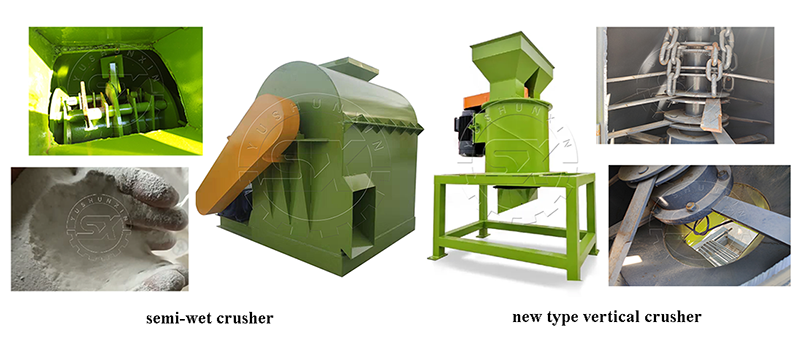

Adjust the particle size

According to the experimental data, when we crush the material before fermentation, their degradation rate can be more than doubled. Because the smaller the material particle size, the larger the oxygen contact area, the better aerobic fermentation effect. Here, both new type vertical compost crusher and semi-wet fertilizer grinder are excellent choice for manure crushing.

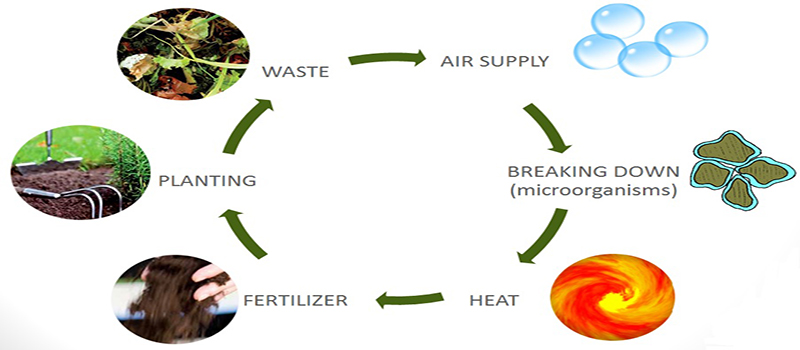

Aerobic hot composting and turned regularly

Finally, the most important step is turning manure piles regularly to speed up aerobic hot composting. In the enough supply of oxygen, microorganisms can rapidly decompose organic matter in poultry manure. And generated heat can kill harmful substances in raw materials. So, while the poultry wastes composting process, you need to turn the compost piles.

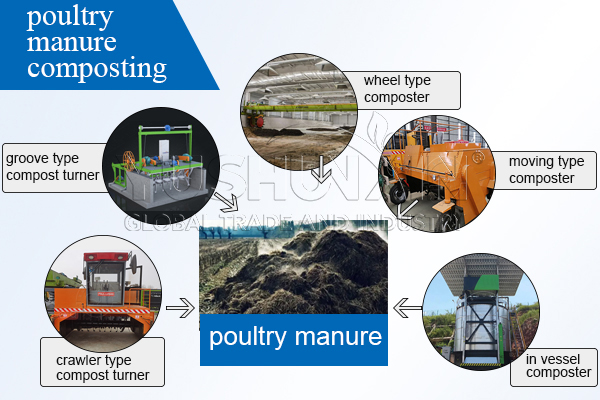

Practical and best-selling fermentation equipment you can choose for your poultry manure composting process

The poultry manure composting equipment from SEEC are designed according to the aerobic fermentation technology. This is the most advanced composting technology for poultry waste disposal. For this, we design various professional compost fertilizer making machines, which make your poultry manure composting process will go smoothly. Here are some typical and best-selling fermentation equipment you can choose from SEEC. If you have any questions about them, just feel free to contact us. As a fertilizer equipment manufacturer for more than 30 years, we can provide you with the most professional guidance and high quality poultry manure processing machines.

Economical poultry compost turner for sale

If you need a economical compost turner for poultry manure processing, we recommend you buy our groove type compost machine. It can compost poultry litter in a fermentation tank with a width of 2.5-5 m and a depth of 0.8-1 m. With transfer vehicle, it even can help you finish large scale manure composting. What’s more, a groove type composter only needs $60,000-$20,000.

Equipment for on the ground fermentation of poultry waste

But provided you don’t want to build fermentation grooves, we also can offer you windrow compost equipment. It can start poultry manure composting on the flat cement ground directly. In this process, you only need to pile poultry manure materials into windrows with a width of 2-3 m and a height of 0.6-1.5 m. Then by driving windrow composter, you can turn 400-1500 m³ of poultry litter piles per hour.

Large scale poultry manure composting equipment

Is there a larger capacity poultry manure compost equipment? Of course. For large scale manure compost making, the best-selling machine is wheel type compost turner. It has a turning span of 8-30 m and a turning depth of 1-3 m. In addition, it also has a fully automated electrical control system. So after presetting working parameters, it can move to compost poultry manure without any options.

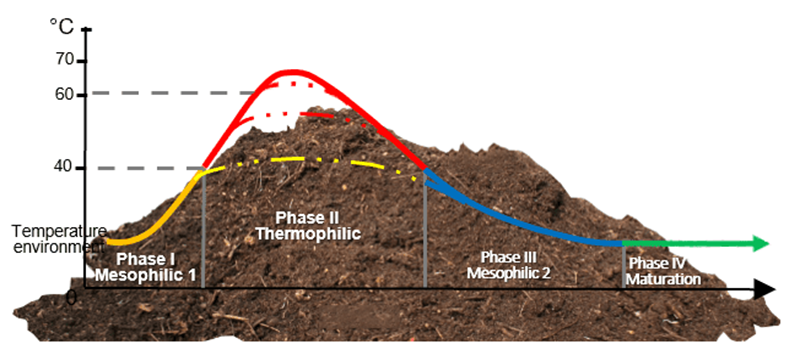

How does poultry manure composting system recognize the fermentation is done and the manure is fully composted?

In generally, the poultry manure composting machine need to stir compost piles frequently. Then the temperature of materials can quickly increase to 60 ℃, which is hot enough to kill harmful substance in poultry manure. Then you need to turn over compost materials regularly to prevent the temperature from over 70 ℃. This is the key to keeping the activity of beneficial bacteria. When the temperature drop to 30 ~ 45 ℃, the less times you should do turning work. Finally, when the temperature no long changing, the poultry farm waste is fully fermented. For effective turning, compost turning machine is important.

What you can do for further process poultry manure compost into organic fertilizer?

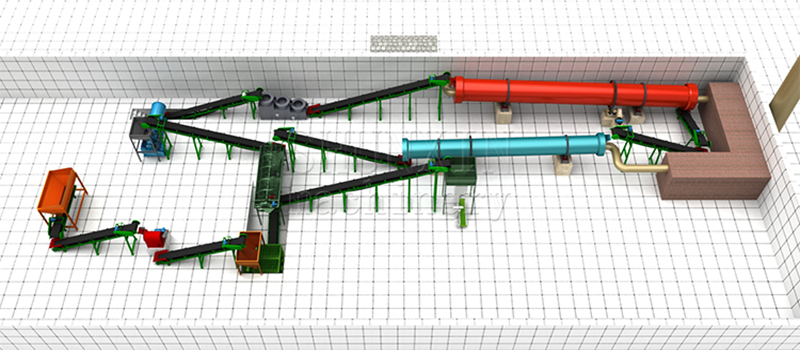

Becoming a poultry organic fertilizer manufacturer, you can choose to produce two forms of products, powdered and granulated. So, we have designed different kinds fertilizer production lines for you. Generally speaking, after you finish the poultry manure composting process, different processing method makes different forms fertilizer products. In a word, granulated fertilizers making process are more complex than powders. Meanwhile, you need to prepare more budget on pellets fertilizer making project.

How to convert poultry waste to organic powdery compost fertilizer for sale?

So, in order to cut the budget, you can choose powder organic fertilizer production line to convert poultry waste to organic powdery compost fertilizer for sale. For powdery compost fertilizer production line, it is a small scale fertilizer production project. In general, you need four compost processing equipment on the flow chart: high position manipulator palletizing machine, vertical compost crusher, screen machine, cache materials warehouse and packing equipment. If you have any questions about this poultry manure processing technologies, just contact us freely. We can provide customized service for this production line.

How to turn poultry manure compost into pellets organic fertilizer?

Unlike powdery fertilizer making, you need poultry manure pellet machine to help you make fertilizer granules. The poultry manure pellet machine from SX is a kind of professional granulating equipment to make materials into special shape. If you want to compost poultry manure into pellets fertilizer, there are different types organic fertilizer granulator you can choose: new type organic fertilizer granulator, double roller extrusion granulator, disc pellet machine and rotary drum granulator. They have high ball rate and the pellets are more beautiful.

How does a poultry manure pelletizing machine work?

Our poultry manure pellet machine mainly adopts wet granulating method to make pellets from composted materials. This granulation method has high granulating rate, the granule is more beautiful. what’s more, it saves energy a lot. After poultry manure composting process, your composted materials need to be entered into granulating process. The high speed rotary mechanical agitation in pellets machine can mix, granulate, balling and densify the powder materials. Finally, you can get pellets fertilizer from poultry wastes.