Compared with powdery fertilizers, granular fertilizers have better fluidity. That is, granular fertilizer is more convenient to transport, store and use. Because after granulating, your fertilizer has a lower possibility of sticking and layering. Therefore, more and more fertilizer manufacturers invest in granular fertilizer making plants. Thus, how to make granular fertilizer? What equipment is needed in the fertilizer granulation line? What is the price of a fertilizer granulation plant setup?SX can provide you with all answers.

Get details design for your fertilizer granulation plant!

How to make granular fertilizer? What equipment is needed in the fertilizer granulation system?

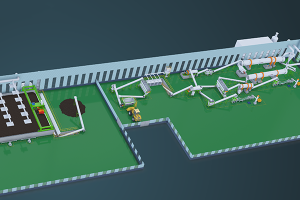

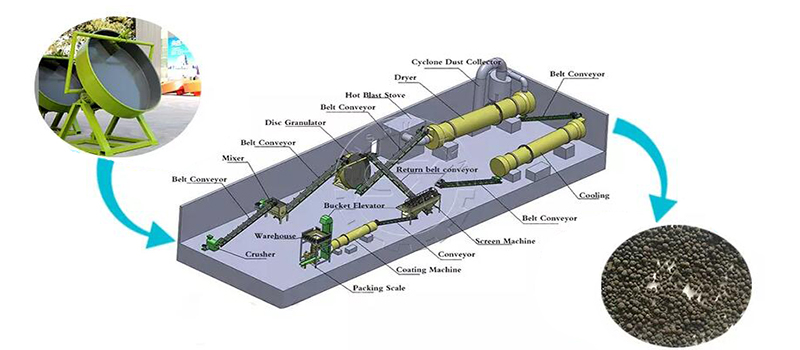

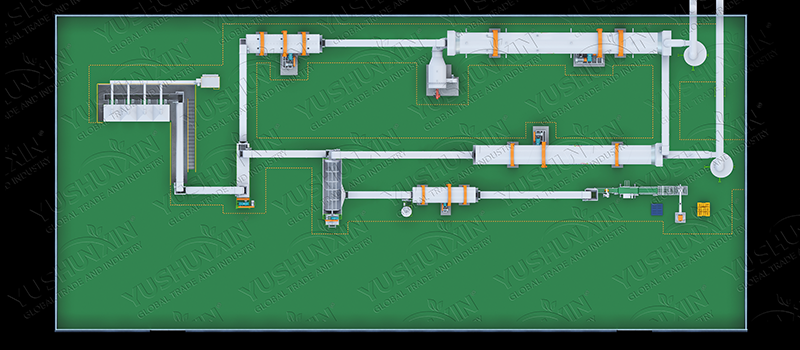

In order to make high quality fertilizer granules, it is necessary to understand the steps of a complete granular fertilizer production line. And what equipment is suitable for each process? A complete fertilizer making system usually contains 7 steps as follows:

Batching fertilizer materials

Whether you plan to produce organic or compound fertilizer, you will use a variety of raw materials. So it is essential to strictly feed these materials in required proportion. Here, SX batching machine can help you a lot.

Crushing into powder

In general, the finer the raw material, the easier the granule making, the smoother the final fertilizer pellet appearance. So if you make fertilizer for commercial purposes, it is advisable to grind fertilizer materials with crusher before granulation.

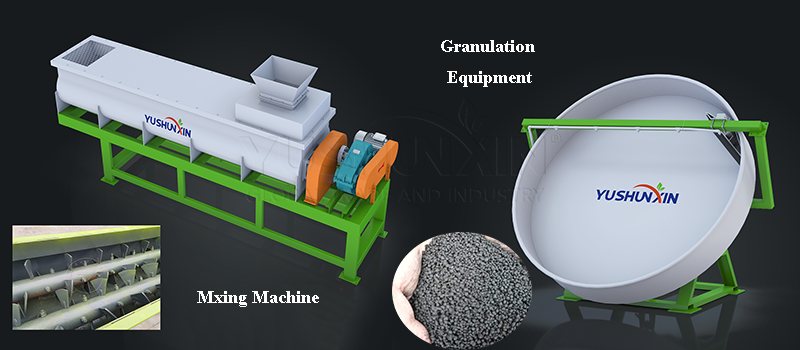

Mixing for nutrient balance

If you want to prevent final fertilizer particles from nutrients imbalance, you can buy a fertilizer mixing machine for your fertilizer granulation line. Because it can blend various materials evenly in a short time.

Granulation of organic and compound fertilizer

It is the most important step in fertilizer pellet manufacturing. For this, SX can offer you various granulators for your choice. Whether you want to make organic fertilizer or produce compound fertilizer, start a start a small scale or large scale fertilizer granulation plant.

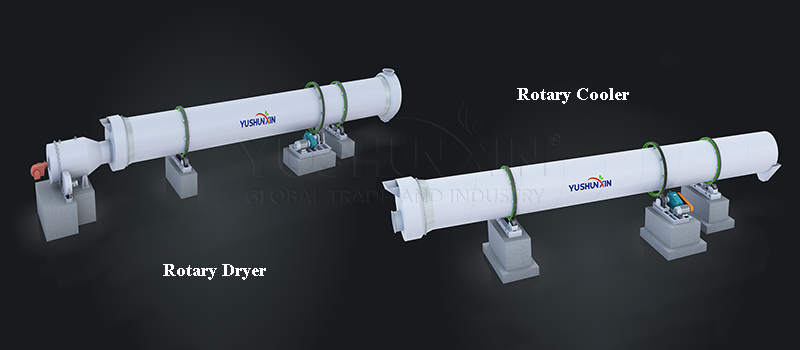

Drying and cooling

If you use dry granulation machine, it is dispensable to purchase dryer and cooler. But when you process fertilizer granules with wet granulation equipment, dryer and cooler are necessary. They can help you remove excessive moisture from fertilizer pellets quickly and make it meet the international moisture requirements. Moreover, your fertilizer is easier to transport and can be stored for a long time.

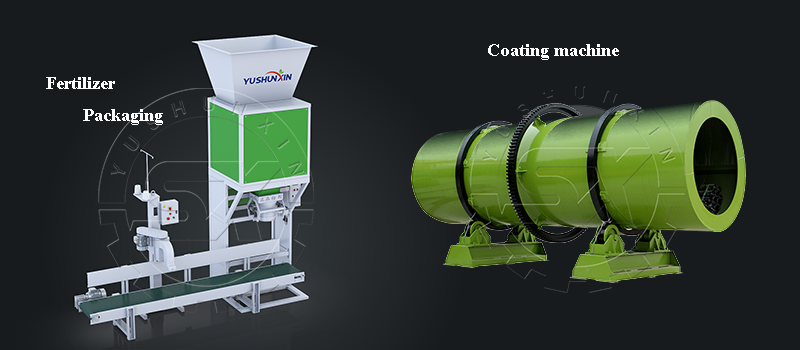

Coating for easier transport and storage

Usually, you will find that the granular fertilizer will become easy to stick again after a long time storage. And the effect fertilizer will decrease . But if you add a protect film to fertilizer pellets with coating equipment. The fertilizer granules will have a longer storage time and a longer fertilizer effect.

Packaging to sell

This is the final process of the granular fertilizer production line. When you pack your fertilizer into different volumes of bags, you can earn the favor of customers with different needs.

If you want to make granular fertilizer from organic waste, you also need to purchase a manure compost machine. Which can help you complete the harmless process of manure faster. You can choose equipment according to your needs.

How many types of granulation machines can you choose in SX?

Fertilizer granulation line, as name suggests, pellet making machine plays an important role in this system. But there are various granulation machines in the market, which one is more suitable for you? There are some tips for your reference.

Small scale pan granulation machine for low cost fertilizer pellet making

If you want to start a small scale fertilizer granulation, we recommend you choose disc pan granulator. It is the most cost-effective small scale fertilizer pelleting machine in SX. For one thing, it has a capacity of 0.5-6 t/h, which can fully meet your requirements of produce fertilizer particles in a small scale. For another, it has a favourable price, only about $1,500-$16,000. And its granulation rate can reach over 93%. It means you can greatly reduce material consumption in the granulation process. Therefore, it can help you produce fertilizer particles at a low cost, whether it is organic fertilizer making or compound fertilizer manufacturing.

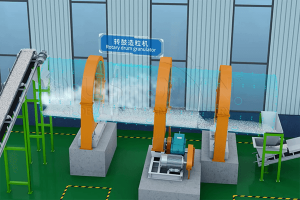

Large scale drum pelletizer for NPK fertilizer granulation

But when you want to buy a equipment for large scale fertilizer pellet making, especially the NPK fertilizer making. The rotary drum pelletizer is your best choice. Because its largest production capacity is 30 t/h, which is much higher than any other granulation machine. And in order to prevent the erosion of a large amount of chemical fertilizer granulation, we especially add a rubber lining to drum granulator. Therefore, it can finish large scale granular NPK compound fertilizer production easily. And it can be used in preparing low, medium and high concentration of compound fertilizers

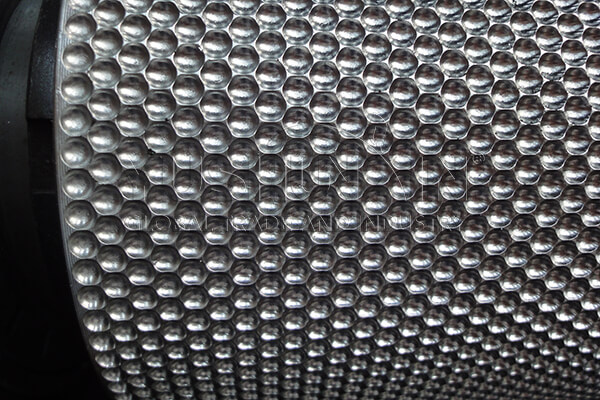

Double roller granulator for low content moisture material pelleting

The above two granulators both adopt wet granulation method, which uses liquid as binder to enhance the cohesive force between materials. But is there a pelletizer of dry fertilizer granulation? For this, SX can offer you double roller granulation equipment. It mainly relies on the extrusion force of two rollers to make chemical and compost powder into fertilizer particles. It is nearly no water involved. So you don’t need to buy dryer and cooler for double roller fertilizer granulation line. Then this machine also can greatly reduce your budget for granular fertilizer manufacturing.

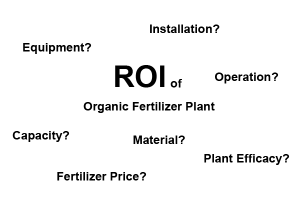

What is the price of the granular fertilizer production system?

In the process of choosing production line for your fertilizer making plant, price must is an item you are interested in. You can know the detailed design and price of fertilizer production line from the following.

1-3 t/h disc fertilizer granulation line price

The 1-3 t/h disc fertilizer granulation line is worth about $10,000-$80,000. It is more suitable for small scale and low cost organic and compound fertilizer preparation. In addition, if you want to start a 1-3 t/h granular fertilizer making, you also need to spend money on factory area rent. For 1-3 t/h disc fertilizer granulation line, you should prepare an area of 1,000-3,000 ㎡ (about 0.25-0.8 acre).

- Model: 1-3 t/h disc fertilizer granulation line

- Budget: $10,000-$80,000

- Configuration: Groove type compost turner, SXSF-60 semi-wet compost crusher, batching machine, SXWJ-7015 horizontal mixer, SXYZ-2800 disc granulator, drum dryer, drum cooler, coating machine, granule screen and granular fertilizer packager, belt conveyor and so on (Depend on actual conditions).

- Occupied land Area:1,000-3,000 ㎡(about 0.25-0.8 acre)

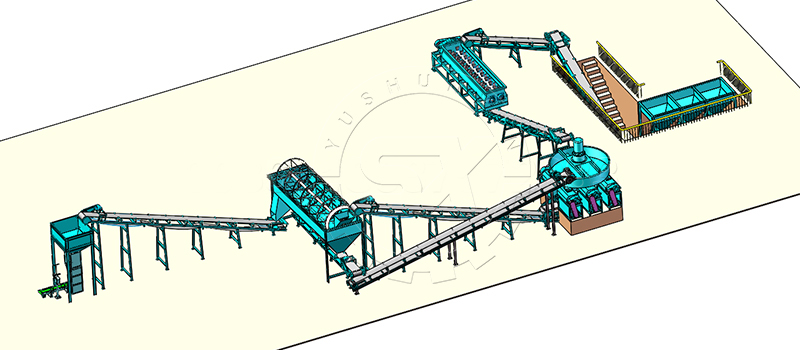

How much does this 5-10 t/h double roller fertilizer pelleting system

The price of a 5-10 t/h fertilizer pelleting system usually is $20,000-$150,000. Then in general, this production line will occupy an area of 1,500-5,000 ㎡ (about 0.5-1.3 acre). If you want to use it produce medium scale NPK compound fertilizer. You can buy a double roller granulation line. It doesn’t need to spend money on composting machine, dryer and cooler. So you can finish compound fertilizer making at a lower cost. You need to prepare $20,000-$150,000 to purchase this line.

- Model: 5-10 t/h double roller fertilizer pelleting system

- Budget: $20,000-$150,000

- Configuration: Batching machine, SXLTF-800 chain crusher, SXPJ-2200 disc mixer, double roller granulator, rotary sieving machine and granular fertilizer packing machine, belt conveyor and so on (Depend on actual conditions).

- Occupied land Area:1,500-5,000 ㎡(about 0.5-1.3 acre)

What is the cost of this 10-20 t/h rotary drum fertilizer making line

If you want to set up a large scale fertilizer manufacturing plant, you can choose rotary drum pelleting line. A complete rotary drum granule making system is worth about $10,000-$40,000. In addition, you need to prepare a 3,000-8,000 ㎡ site to install the entire fertilizer production line. Using rotary drum pelletizer in your granular fertilizer production process can not only enlarge your fertilizer plant capacity, but also reduce the consumption of energy.

- Model: 10-20 t/h rotary drum fertilizer making line

- Budget: $10,000-$40,000

- Configuration: Wheel type compost turner, SXFLF-1000 vertical compost crusher, dynamic batching machine, SXWJ-1630 horizontal mixer, SXZGZ-3210 drum granulator, drum dryer, cooler, coating machine, rotary sieving machine and granular fertilizer packing machine, belt conveyor and so on (Depend on actual conditions).

- Occupied land Area:3,000-8,000 ㎡(about 0.8-2 acre)

Can the systems process phosphate fertilizer granules?

The answer is yes. Whether disc, roller press or rotary drum granulation system, they are ideal choice for phosphate fertilizer granules production. Especially, the SSP pellets making. You can choose the best one according the capacity and budget for your phosphate fertilizer plant. But, to reduced the acid erosion to the equipment, we recommend you replace the disc and rollers with stainless steel made and 4Cr13 roller sheets respectively.

In addition, as mention above, the systems can fully meet your requirements of organic fertilizer pellets making and complex fertilizer granulation. Including cow dung pellet making, chicken litter granulation, NPK pellets production, ice melt granule manufacturing, etc.

Get your customized fertilizer granulation solution now!

Successful solutions for organic and compound fertilizer granule making all the world

If you want to learn our fertilizer granulation lines in details, there are some videos and solutions from our past successful cases all the world for your reference. Such as

- Cow Manure fertilizer granualtion with Lime in Ecuador

- $50,000 Biofertilizer Manufacturing Plant In Vietnam

- 5 TPH Compound Fertilizer Granules making In Bolivia

- SSP Granule production factory In Egypt

- Snow Remover Granulation In Korea

- 100 T/D NPK Fertilizer Making Line For Turkey

Welcome to contact us immediately to get your own fertilizer pellet making plan!