Organic fertilizer manufacturing plays an important role in the process of modern agricultural production. Compared with chemical fertilizer, organic fertilizer is more healthy for the growth of crops. So more and more people are willing to invest in organic fertilizer production plant. And most of them choose to start with small scale organic fertilizer production. For this, YUSHUNXIN can provide you with many professional organic fertilizer production machines. What’s more, according to your actual situation and demand, we will makes use of the machine to design a customized organic fertilizer production line for you.

Main Parameters

- Capacity: 1-10 t/h

- Final shape: Powder or granule

- Final granule size: 1-10 mm

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application materials: animal manure, straw, rice husk, sawdust, mushroom waste, biogas residue, etc

- Cost: $50,000-$300,000

Get your customized small scale organic fertilizer production plan!

How can you produce organic fertilizer in small quantities?

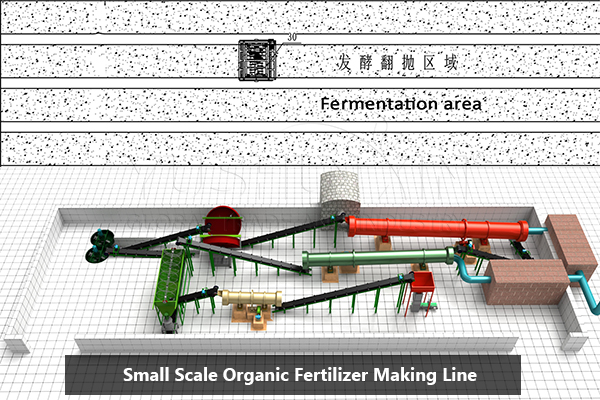

In general, a complete organic fertilizer production line includes compost turners, crusher, mixer, granulator, screening machine, dryer, cooler, coating equipment and packaging facility. Besides, you also need some auxiliary equipment to connect the whole production line well. Such as belt conveyor, batching machine, dust collectors and so on. With these fertilizer machines, you can freely choose to make organic fertilizer in powder and granules in a small scale according to your needs.

- If you are finding a small scale organic fertilizer making line with simple process, economical price, small area needed, etc. The powder organic fertilizer manufacturing system is the best choice. It only contains 5 steps: composting, batching, crushing, screening and packing.

- But, when you pay more attention to make more profits in a long term, it is advisable to buy small scale organic fertilizer granule making line. With more sophisticated process, it can turn organic waste into quality fertilizer pellets with balanced nutrients, uniform size, longer storage time, etc. So, it can bring you higher profits.

Top 2 powder small scale organic fertilizer line for sale

If you want to build a small scale organic fertilizer plant for powder organic fertilizer making, buy right types of fertilizer equipment is important. In general, there are 2 solutions that many fertilizer manufacturers are interested in. They can fully meet your requirements for 1-10 t/h powder organic fertilizer making.

1-5 t/h organic powder fertilizer making plan

As mentioned above, the powder organic fertilizer making line needs 5 machines. Compost turner, batching machine, crusher, screener and packaging equipment. Then, for 1-5 t/h output, it is advisable to buy them of the following types:

500-1500 m³/h Crawler type compost turning machine

For a composting in a 5 t/h powder organic fertilizer production plant, the most economical choice is crawler type windrow compost turner. With 2.4-3m turning width and 0.6-1.5m composting depth, it can turning 500-1500 m³ of organic compost windrows per hour. This can fully meet your requirements of 1-5 tons of organic compost fertilizer making. In addition, using it, you can decompose organic waste (to kill harmful bacteria, pest eggs and grass weeds) on the ground directly, both indoor and outdoor.

Windrow Compost Turner

- Turning width: 2.4-3 m

- Turning Depth: 0.6-1.5 m

- Capacity: 500-1500 m³/h

- Compost Time: 15-20 days

- Material: Q235 Carbon steel, etc

Crusher for making organic fertilizer in a small scale

Then, for turning compost to powder organic fertilizer, the most important step is fine powder processing. This makes your organic fertilizer has better performance in nutrient absorption. But, how to crush compost into fine powder of 1-5 t/h quickly? It is using a professional fertilizer grinder, the semi-wet material crusher. It can fully meet your requirements for powdered organic fertilizer manufacturing in a small quantities of 1-5 t/h while has characteristics of economical price and small space needed.

Semi-wet crushing machine

- Capacity: 1-8 t/h

- Crushed Size: 50 mesh

- Power: 22-75 kw

- Area: 1-6 ㎡

- Feeding Moisture: 30%-50%

Rotary screen machine from YUSHUNXIN

For screening process, YUSHUNXIN recommend you rotary screen machine for your small scale organic fertilizer production. And the SXGS-1240 rotary ssieving machine is the best choice for 1-5 t/h powder fertilizer screening. It can remove waste like stones, cigarette butts, large particles, etc from produced organic fertilizer to improve the quality. During the working process, it has high screening efficiency and low noise. And the galvanized screen is more durable.

Rotary screener machine

- Model: SXGS-1240

- Capacity: 3-5 t/h

- Power: 4 kw

- Feeding Size: <300 mm

- Mesh material: Galvanized steel

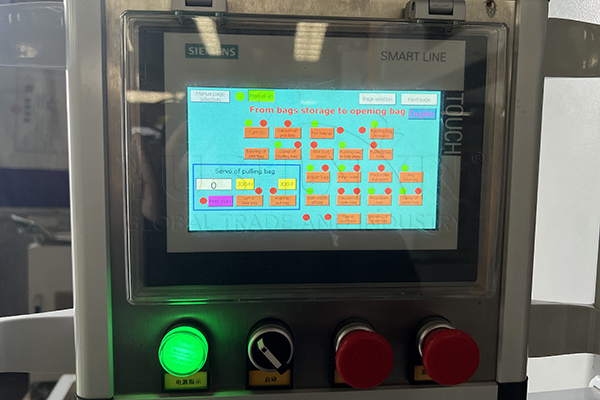

Fertilizer packing machine

Packing is the final process in organic fertilizer production line. YUSHUNXIN automatic quantitative packing scale is designed for quantitative packaging. For 1-5 t/h powder bagging, the single bucket packing scale is the best choice. Can fully meet your requirments of 5-50 kg/bag of powder fertilizer packaging and sealing.

Single Bucket Paking Machine

- Model: SXBZ-50

- Packing Weight: 20-50 kg/bag

- Capacity: 4-6 bags/min

- Function: Automatic weighing and packing

5-10 t/h powder small scale organic fertilizer making machines

But, when it comes to set up a powder small scale organic fertilizer making plant of 5-10 t/h, YUSHUNXIN recommend you replace composting, crushing with groove compost turner and vertical grinder.

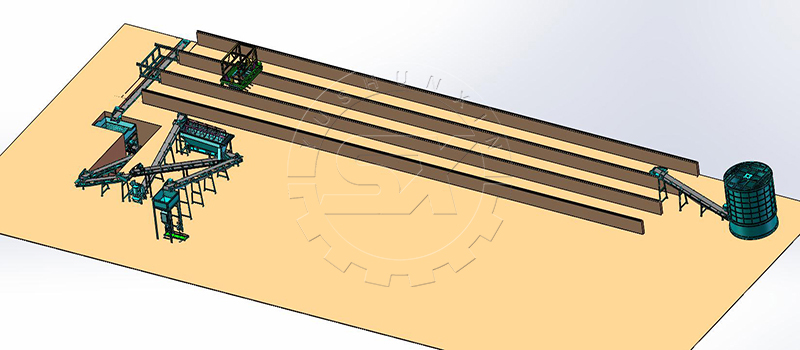

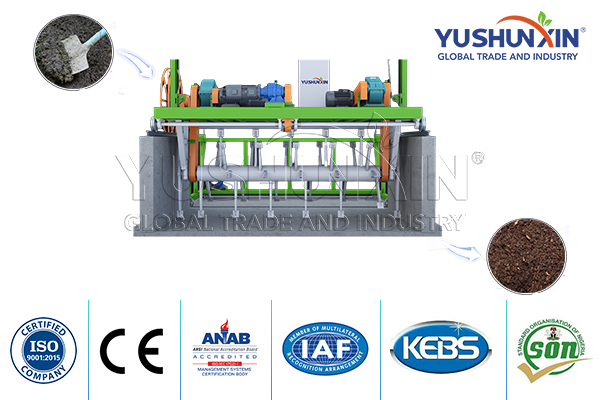

Groove type compost turner for small scale organic fertilizer plant

If you want to start a small scale compost organic materials in farm. Groove type compost turner is an excellent choice for you. It has a turning width of 2.5-5 m and turning depth of 0.8-1 m. So it will not take a lot of spaces in your farm and suitable for small scale composting. When using it, you can collect your organic wastes together and start fermentation in the grooves. As times goes by, the temperature of compost piles will increase. Then, you can use this kind compost turning machine to turn over the organic materials for better aerobic fermentation.

Groove type Compost Equipment

- Turning Width: 2.5-5 m

- Turning Depth: 0.8-2 m

- Composting Time: 15-20 days

- Material: Q235 Carbon steel, Mn steel, etc

Vertical crusher for 5-10 t/h organic fertilizer powder making

In addition, for 5-10 t/h organic compost crushing, the vertical grinding machine is more recommended. For one thing, it has model of 8-15 t/h capacity, which can meet the 5-10 t/h small organic fertilizer making plant setup. For another, the unique vertical design greatly reduce the possibility of blocking when crush material with 30%-50% water content.

New type vertical crusher for sale

- Model: SXFLF-1000

- Capacity: 8-15 t/h

- Power: 37 kw

- Inlet Size: 650×450 mm

- Dimensions: 2150x1220x2700 mm

As for rotary sieving machine and bagging machine, you only need to replace them with SXGS-1560 screener (6-10 t/h) or double bucket bagging scale (8-12 bag/min).

How to make organic fertilizers pellets in small quantities?

Can we make organic fertilizer into granules in a small scale? The answer is yes. For small quantities organic fertilizer granulation, there are 2 designs are commonly used in manufacturers.

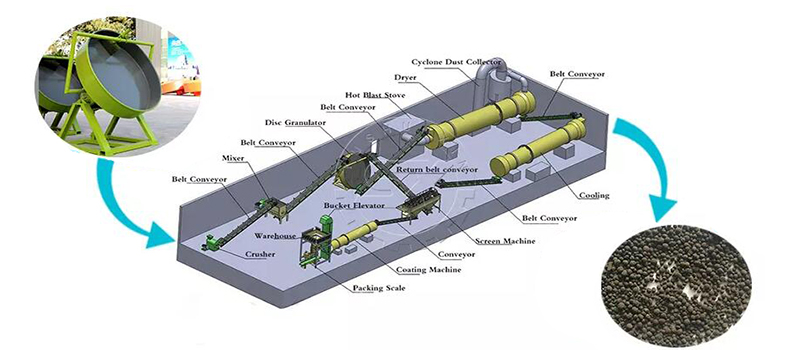

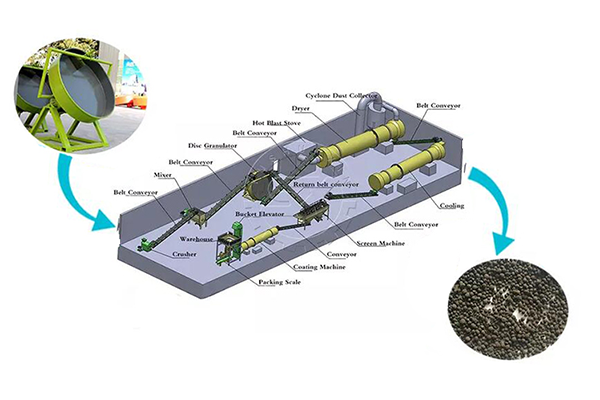

Disc granulation system for economical small scale organic fertilizer pellets making

If you want to produce organic fertilizer pellet in a small scale from wet material, it is advisable to buy a pan pellet system. Because, it can use liquid as binder to speed up the organic fertilizer granules formation. At the same time, it can fully meet your requirements of 1-10 t/h granular organic fertilizer manufacturing. In addition, it also has characteristics of favourable price, over 93% granulation rate, easy operation, 1-8 mm fertilizer granules making freely, etc.

Then, because of wet granulation method used in organic fertilizer manufacturing, it needs drying and cooling subsequently. Therefore, it contains organic fertilizer machines of composting, batching, crushing, mixing, disc granulation, screening, drying, cooling and packaging.

| Equipment | Capacity (T/H) | Granule Size (mm) | Granulation Rate | Feeding Moisture | Cost |

|---|---|---|---|---|---|

| Disc Granulator | 1-6 / set | 1-8 | 93% | 20%-40% | $3,000-$12,000 |

Inquiry the small scale disc granulation line now!

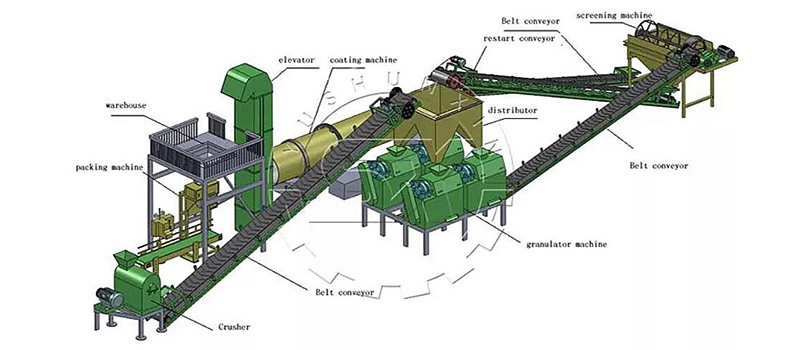

Double roller pelletizing plan for economical organic fertilizer granulation in small quantities

Provided you need a small scale organic fertilizer granulator with a lower cost, you can purchase a double roller extrusion line. It turns cow manure into granules by roller extrusion, instead of liquid. This is simpler and faster method to prepare granular organic fertilizer of lower than 10 TPH. On the contrary, it requires a moisture of lower than 15% when organic compost granulation. Then, with different roller sheet molds, you can choose to prepare 3-10 mm granular fertilizer with flat ball, oval, pillow, etc shapes freely.

In general, for the dry granulation system of organic fertilizer, you only need to buy 6 machines. Composting machine, batching equipment, crusher, screener, roller press granulator, packaging scale.

| Equipment | Capacity (T/H) | Granule Size (mm) | Granulation Rate | Feeding Moisture | Cost |

|---|---|---|---|---|---|

| Roller Granulator | 1-4 /set | 3-10 | 95% | <15% | $4,000-$15,000 |

In addition, there are also many other organic fertilizer granulation lines for small operation. Such as economical flat die pelletizing line, erosion resistance drum granulation system, stirring teeth granulation plan for high hardness pellets making, etc.

Get your own small scale organic fertilizer production plan now!

Can small scale organic fertilizer manufacturing systems used to 1000 cows dung management?

Of course. If you have a cattle farm with 1000 cows and you want to make organic fertilizer from cow dung, they can fully meet your requirements.

In general, a cow will generate about 30 kg of manure waste a day. With 1000 cattle, you need to dispose of cow dung of 30 tons per day. Then, our small scale organic fertilizer production lines has a capacity of 1-10 t/h. Therefore, they can turn cattle litter into powder or granular organic fertilizer of 20-200 tons per day. Moreover, it is also suitable for dispose of manure waste in farms of 1 million birds, 50,000 pigs, etc. If you are not clear is the small scale organic fertilizer making lines suitable for you, welcome to contact us for answer now!

How much it costs to set up small scale organic fertilizer plant?

Generally, for a basic small fertilizer production line (1–10 tons per hour), the total cost ranges from $35,000 to $300,000. And the powdery organic fertilizer manufacturing cost is usually lower than the granular organic fertilizer production.

Powder organic fertilizer making line costs $20,000-$60,000

It contains compost turner, batching machine, crusher, screener, packaging machine and belt conveyor.

- 1-3 t/h capacity one needs a investment of $20,000-$35,000.

- 3-5 t/h system, you may need to prepare $35,000-$45,000.

- 5-10 t/h output pricing about $45,000-$60,000.

Granular organic fertilizer production system pricing $80,000-$300,000

This includes machines for composting, batching, crushing, mixing, granulating, screening, drying, cooling, coating, packaging and belt conveyor.

- 1-3 t/h capacity one needs a investment of $80,000-$120,000.

- 3-5 t/h system, you may need to prepare $120,000-$180,000.

- 5-10 t/h output pricing about $180,000-$300,000.

Moreover, there are also additional costs may include land and infrastructure (800–5,000㎡), labor and utilities, installation and shipping fees, etc. If you want to get precise investment for your organic fertilizer making plant setup, welcome to contact us now! As a source factory, YUSHUNXIN can offer you a customized design and source price.

How about the large scale organic fertilizer manufacturing? What are the differences from the small scale organic fertilizer production?

If you want to start a large scale organic fertilizer making, you need to focus on the difference from the small scale one as follows:

What can YUSHUNXIN do during build a small organic fertilizer

YUSHUNXIN, is a professional organic fertilizer equipment manufacturer from China. It was founded in 2005 and has engaged in organic fertilizer equipment production for nearly 20 years. If you want to buy organic fertilizer production equipment for your small scale fertilizer plant, YUSHUNXIN is a good choice for you.

Because our professional engineers can design a reasonable plan for your plant according your budget, space, capacity and material. And we will help you select the most suitable fertilizer facility for your organic fertilizer making factory. In addition, if you have any special requirements for fertilizer processing equipment, YUSHUNXIN also can provide customized service for you. We will try our best to help you build your organic fertilizer factory.

In addition, there are also compound fertilizer making line, bio fertilizer production plan, liquid fertilizer manufacturing systems, etc for you. Welcome to contact us for your own fertilizer machines and project designs now!