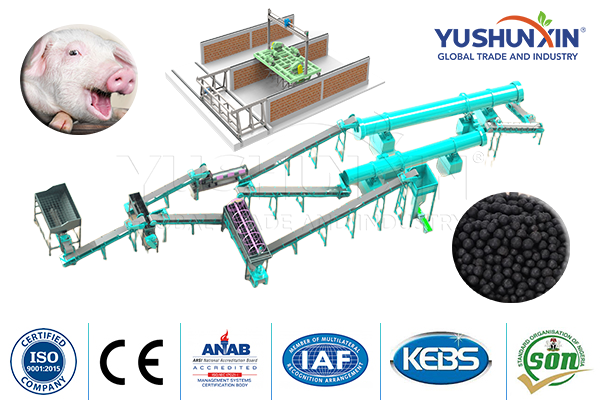

For pig waste management, making into organic fertilizer is most economical method. It can dispose of piggery manure effctively while making extra profits for your pig farms. Then, how to make pig manure into organic fertilizer? The answer is not fixed, because it is influenced by many factors. For example, making pig manure into powder or granular fertilizer? At low cost or enough budget? In a small or large scale? But no matter what the situation is, YUSHUNXIN can design the most suitable fertilizer machines for your swine dung fertilizer production project. In the whole process, what you must focus on is composting and granulation of pig poop. Because composting can eliminate harmful bacteria, pest eggs and grass seeds in manure. And making swine droppings into granules will make your fertilizer more convenient to transport, store and use. Welcome to contact us for your own pig manure fertilizer machine.

Main Parameters

- Capacity: 1-20 t/h

- Final shape: Powder or granule

- Granule size: 1-10 mm

- Cost: $30,000-$500,000

- Area: 800-10,000 ㎡

- Application: Pig farm manure management, organic fertilizer making.

What is the most economical pig waste management method?

It is pig manure compost making. Compared with other piggery waste disposal system, it only requires a low investment, which is on pig manure dewatering and aerobic fermentation. These will retain the nutrients in swine manure and kill pathogens, pest eggs and weed seeds.

Why need manure dehydrator in pig waste fertilizer making?

To decompose pig manure quickly, it is important to create a suitable environment for fermentation microorganisms reproduction. One of the necessary conditions is to keep pig manure moisture at 40%-60%. Which can offer enough water to microorganism activity but not hinder the transport of oxygen. Here, manure dewatering machine can dry pig manure to reduce the water content from 50%-90% to 30%-40% in a short time.

Inquiry more about pig manure disposal!

How to buy the best pig manure composting equipment?

It is depended on your actual requirements for swine manure waste disposal. Such as,

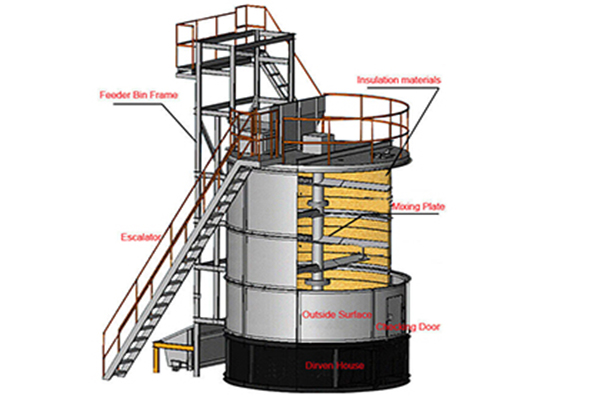

- To ferment pig manure fastest, organic fertilizer fermentation tank is the best choice. Closed fermentation method for swine farm waste, which can isolate influence from outside world. In addition, it is automatic of material feeding, aeration, mixing, temperature monitoring, product discharging, etc.

- Then, the most economical piggery manure compost machine is the groove type compost turner. With 3-5 m turning width and 0.8-2 m turning depth, its price is only $6,500-$19,000.

- Also, for a large scale composting of pig manure, there is wheel type compost turner for you. It enlarge the turning span to 8-30 m and turning depth of 3 m. Which can fully meet your needs of more than 10 t/h pig manure compost making.

Get your own piggery manure compost machine!

How to make swine manure into powdery organic fertilizer?

If you want to further process pig manure compost fertilizer better, and with a smiple process and low cost, we recommend you choose to process it into fine powder.

After composting, it only need to process piggery manure with material batching, crushing, screening and bagging. These will turn composted pig dung into fine powder organic fertilizer, which is easier to be absorbed by crops and planrs. Moreover, the simple process also means fewer organic fertilizer machines and less space occupations. So you can spend less on pig manure fertilizer equipment buying and workshop rent. In general, the price of a powder fertilizer making line, including the swine manure compostor, for pig manure processing is $30,000-$90,000. The smallest powdery fertilizer making line only needs 800 ㎡ of area to install.

Get the latest quotation of your pig manure fertilizer making plan?

How to choose the right equipment for making fertilizer pellets from pig manure?

When you want to make pig manure into granules, you also need to focus on the selection of organic fertilizer granulator. From the data of our past customers, we find there are 2 fertilizer pelletizers that are very popular with pig manure fertilizer manufacturers. They are:

Disc pan granulator for small scale fertilizer making of pig dung

There are two reasons why so many fertilizer plants choose disc granulator to process pig manure into granules. For one thing, it has a high granulation rate, which can reach over 93%. This means that within a certain time, you can produce more fertilizer particles with the same amounts of pig liter compost. For another, it has a favourable price, which is lower than other organic pellet machines. About $1,500-$16,000. In addition, it has a capacity of 1-6 t/h, so it is an ideal choice for making granular fertilizer from pig manure in a small scale.

Rotary drum pelleting machine for large scale pig manure granulation

Then rotary drum pelletizer is the best selling granulation machine with large scale pig waste fertilizer making customers. First, because it has a higher output than other pig dropping granulators, which can reach 30 t/h. It can fully meet your needs for large scale pig manure granulation. Moreover, we especially add a rubber lining to drum pellet making machine, which has a high performance in corrosion-resistance. It can reduce the erosion of the processing of a large amount of pig manure and prolong the service life of the rotary drum pellet manufacturing machine.

Besides the above pellet making machines for swine poop granules making, we also have new type organic fertilizer granulator and flat die pelletizer for your choice. If

How to further improve the quality of the swine waste fertilizer you prepare?

If you want to further improve the quality of your swine waste fertilizer, you can purchase a complete granular organic fertilizer manufacturing line. Besides compost equipment and granule making equipment, it also needs pig manure organic fertilizer machines as follows:

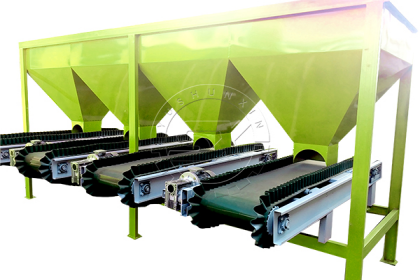

- Batching machine: In order to ensure sufficient nutrients contained in fertilizer, usually we will add some auxiliary materials to pig manure. At that time, batching machine can help you control the amounts of these materials.

- Crusher: If you want to make swine dung fertilizer with a beautiful appearance, crushing machine is necessary. It will break agglomerated pig dung into fine powder, which makes final fertilizer granules have a more smooth surface.

- Mixer: Mixing machine can blend various materials evenly, so that the nutrient of your final fertilizer are balanced.

- Screener: Screener is the key machine for distinguishing qualified from unqualified pellets. And the unqualified pellets will be returned to regulation. This can greatly reduce the waste of materials.

- Dryer and cooler: Dryer and cooler will further remove the moisture of fertilizer granule to make it meet the international requirement. Then the quality of fertilizer pellets will also improve.

- Coating equipment: Coating is a process to add a protective film to your swine waste fertilizer pellets. It will make your fertilizer store for a longer time.

- Packaging scale: After packing, the finished fertilizer is convenient to store and transport. And you can pack them into bags with different volumes, which can meet the different needs of your customers.

How to produce granular organic fertilizer from swine dung at a low cost?

Can we process pig manure into fertilizer granules at a low cost? Of course. You can buy compost machine and granulation equipment for your pig dung fertilizer making plant only. The former can help you remove harmful substances and smelly odor from swine manure. While the latter will make powder pig dung compost into pellets. They are the most important equipment for granular pig waste fertilizer production. In addition, this business plan can be divided in large scale and small scale.

Small scale low cost granular pig manure fertilizer making design

Provided you plan to start a low cost granular pig poop organic fertilizer making in a small scale, windrow compost turner + disc granulation machine is an idea choice for you. Usually, windrow compost machine can process 500-1500 ㎡ of pig manure compost per hour. And pan pelletizer can produce 1-6 tons of swine waste granules per hour.

Large scale low cost swine waste fertilizer pellet production plan

However, when you want to finish a large scale granular pig manure fertilizer production, you can choose wheel type compost turner and drum granulation equipment. They are especially designed for large scale fertilizer fermentation and pellet making.

Pig manure fertilizer production line case In Bulgaria

Pig Manure Disposal into Fertilizer Line

- Conutry: Bulgaria

- Capacity: 3 t/h

- Material: dewatered pig waste

- Final product: pellets

- Design: groove type compost turner, vertical crusher, mixer, roller granulator, screener, packing machine, etc.

In addition, as a professional fertilizer equipment manufacturer, we also can offer you customized fertilizer making plan according to your material. There are also cow dung fertilizer making line, chicken manure disposal plan, poultry manure waste to fertilizer process, etc for you!