Crushing machine is an important equipment in fertilizer making process. YUSHUNXIN can offer various types fertilizer grinders for you. In organic fertilizer production line, you can choose vertical crush machine, high moisture fertilizer crushing equipment and straw waste crusher. In compound fertilizer production line, we have professional chain crusher, urea crush machine and cage fertilizer crusher for sale. Besides, we also design machines to grind wood and mineral materials. If you need a crusher for your fertilizer manufacturing business, welcome to contact us immediately.

Main Parameters

- Capacity: 1-20 T/H

- Crushed Size: 0.3-5 mm

- Grinding Rate: 99%

- Equipment Material: Carbon steel (customized)

- Application: organic compost, organic waste, NPK, mine waste, straw, wood,

Which fertilizer crusher is commonly used in organic fertilizer production?

In general, the material for organic fertilizer making has high moisture. So, you need to buy fertilizer grinder with no blocking and high strength material. For this, both new type vertical fertilizer crusher and semi-wet material grinder are ideal choice.

Vertical fertilizer crushing machine

If you want to grind wet organic fertilizer, the vertical fertilizer crusher is the best choice. It is a kind of adjustable crusher machine without screen cloth. So, when crushing high moisture compost or manure waste, it has strong application and not easy to block. As for capacity, the machine has models of 1-15 t/h. These is the reason why it is one of the most commonly used crushing equipment in both large scale and small scale organic fertilizer production. Besides, there is a observation windrow on this machine. When some vulnerable parts need to be replaced, you can finish the replacement in 10 minutes.

| Model | Power(kw) | Capacity(t/h) | Inlet Size(mm) | Dimensions(mm) |

|---|---|---|---|---|

| SXFLF-600 | 22 | 3-5 | 400*400 | 1300*750*1900 |

| SXFLF-800 | 30 | 5-8 | 600*400 | 1800*1020*2100 |

| SXFLF-1000 | 37 | 8-15 | 650*450 | 2150*1220*2700 |

Economical semi-wet material grinder for sale

But, for those who want to buy an economical fertilizer crushing equipment for organic fertilizer manufacturing, semi-wet fertilizer grinder is here for you. It has a compact design and an more favourable price. Moreover, it adopts advanced crushing technology, which offer higher crushing efficiency than any other crushing equipment. Therefore, it is widely used in different kinds of organic fertilizer production lines. Such as cow manure fertilizer making, chicken poop as fertilizer project, etc, What’s more, according to your actual production demand, we can customize it for you.

| Model | Power(kw) | Capacity(t/h) | Crushed Size(mesh) | Inlet Size(mm) | Dimensions(mm) |

|---|---|---|---|---|---|

| SXSF-40 | 22 | 1-1.5 | 50 | 400*240 | 1200*1350*900 |

| SXSF-60 | 30 | 1.5-3 | 50 | 500*300 | 1300*1450*1300 |

| SXSF-90 | 37 | 3-5 | 50 | 550*410 | 1800*1850*1700 |

| SXSF-1200 | 75 | 5-8 | 50 | 650*500 | 2100*2600*2130 |

Top 2 fertilizer grinding machines for compound fertilizer making

As for grinding equipment for compound fertilizer production, there are top 2 types for you choice in YUSHUNXIN. They are urea crusher and cage grinding equipment.

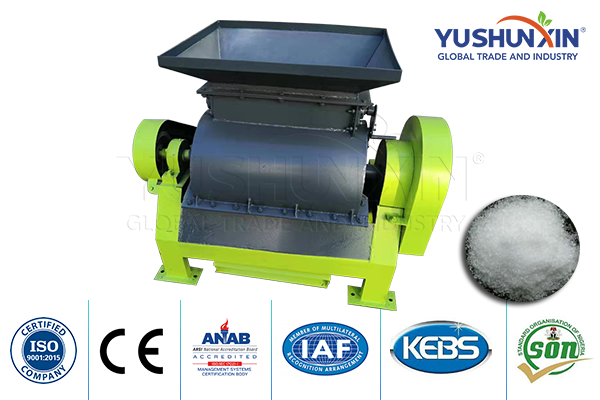

Urea crushing equipment

Urea crusher is used to grind all kinds of single chemical fertilizers with water content less than 40%, especially for materials with high hardness. It mainly makes use of the gap between the roller and the concave plate to grinding and cutting chemical material. The clearance size determines the degree of material crushing. In general, it can offer you 0.3-0.5 mm powdered fertilizer. Before you use this crusher, you should place this machine in a certain position in the workshop. And it can start work immediately after connecting to the power supply.

| Model | Power(kw) | Capacity(t/h) | Feeding Size(mm) | Feed Moisture | Output Size(mm) |

|---|---|---|---|---|---|

| SXNS-40 | 5.5 | 2-3 | <4 | <5% | 0.3-0.5 |

| SXNS-60 | 15 | 4-6 | <4 | <5% | 0.3-0.5 |

| SXNS-80 | 18.5 | 5-8 | <4 | <5% | 0.3-0.5 |

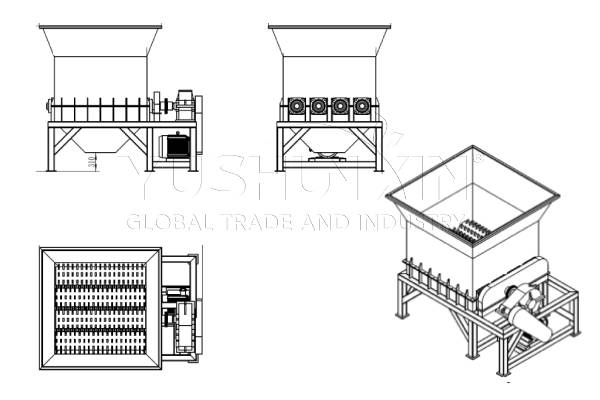

Cage crusher for chemical powder making

The cage fertilizer crusher belongs to medium-sized horizontal fertilizer crusher machine. It mainly makes use of the impact action to crush materials. When it is working, the inside and outside cages rotate in the opposite direction with high speed to generate impact force to make materials become powder. The crusher has various advantages. Including simple structure, high crushing efficiency, good sealing performance, stable operation, easy cleaning, convenient maintenance and so on.

| Model | Power(kw) | Capacity(t/h) | Inlet Size(mm) | Dimensions(mm) |

|---|---|---|---|---|

| SXLSF-600 | 11*2 | 4-6 | 300*250 | 1500*1400*1500 |

| SXLSF-800 | 15*2 | 6-10 | 380*320 | 1500*1500*1500 |

Can you offer a crusher for compound fertilizer lump break in a large scale?

Of course. For large-scale compound fertilizer production and storage, material lump formation is a common issue caused by moisture absorption, long-term stacking, or transportation pressure. Is there a powder making machine to ensure smoothly compound fertilizer making? The fertilizer lump breaker is an ideal choice. With four reinforced crushing shafts, wear-resistant blades, and robust frames, it allows you break hardened fertilizer lumps efficiently.

Is there other grinding equipment to dispose of straw, wood and mineral rocks into fertilizer?

Of course. In order to fully meet your requirements for fertilizer manufacturing, our engineers also design fertilizer crushers for other material disposal. Including straw crush equipment, wood shredder, raymond mill for mine ore breaking and chain plate for returned fertilizer material disposal.

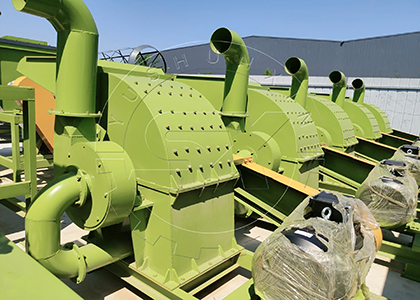

Straw waste crusher for sale

This crush machine is the ideal crushing equipment to crush the corn stalk, straw, peanut husk, bean stalk, cotton wastes, branches, leaves, sawdust, etc. So, if you want to make high quality organic fertilizer, this crusher is necessary to you. For one thing, crushed straw can effectively absorb the excess water in organic manure to reduce the humidity. For another, the agricultural waste is also an ideal choice to adjust C:N ratio for organic fertilizer manufacturing. In addition, straw crusher is also easy to operate and only occupy a small space.

Wood crush machine

If you plan to crush wood logs waste for organic fertilizer manufacturing, there is also professional wood grinders for you. Whether you want to grind logs, branches, bamboo, etc into powder, they can fully meet you needs. Only need a short time, it can turn raw materials into powder with a 0.5-10 mm particle size. Besides, we also can offer you customized wood crusher according to your needs. For example, crushing machine for both straw and logs.

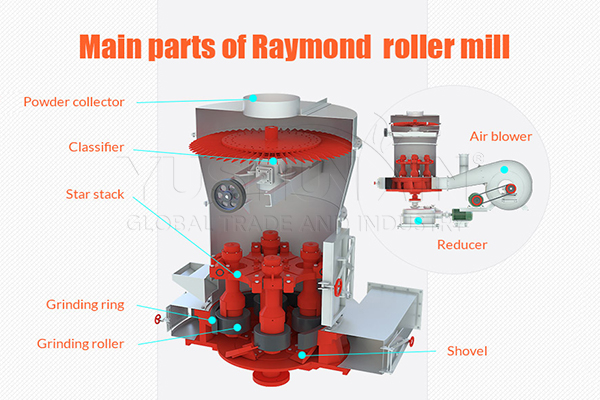

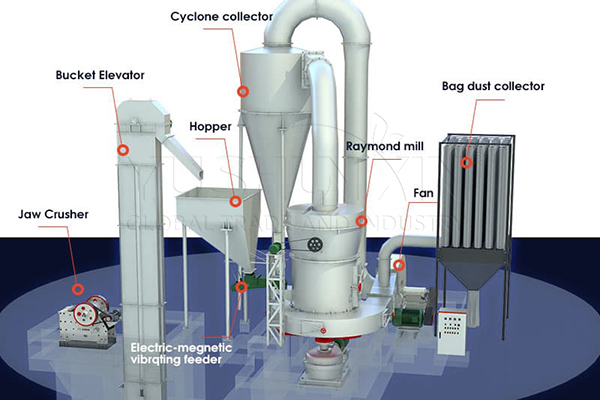

Raymond Mill for mine rocks powder making

However, when you want to add mine waste to fertilizer making, it is advisable to replace with Raymond Mill. With robust grinding ring and rollers, it can grind ore rocks into fine powder quickly. So, it is an excellent option whether you plan to make fertilizer from phosphate rock, zeolite, bentonite ore, etc. The Raymond Mill stands as a time-tested solution for mine ore grinding.

Is there crusher retured fertilizer material disposal

Of course. it is fertilizer chain crusher. It is suitable to crushing nubby materials in compound fertilizer making process. Meanwhile, it is also suitable for the crushing of returned materials in fertilizer production. Its installation form is divided into vertical and horizontal types. The former has single rotor, which is designed for small scale fertilizer making. While the latter has double rotors. Therefore, you can buy it for large scale fertilizer preparation.

Q&A

Q: Which types of crusher is the most suitable one for large scale fertilizer production?

A: New type vertical crusher

If you are doing large scale fertilizer production, SX recommend you to use the new type vertical pulverizer in your fertilizer production line. This machine is the first choice for large scale fertilizer business. Its largest capacity can reach 15 t/h and you can use two even more vertical crushers in a fertilizer manufacturing system. This crushing machine has special material shredding blades, which have high crushing efficiency and longer service life. What’s more, because of no screen mesh, it has strong application for high moisture materials, not easy to block.

Besides crushing equipment, YUSHUNXIN also has many other fertilizer machines for your choice. Such as fertilizer granulation machine, organic fertilizer compost equipment, fertilizer dryer, automatic packing equipment, etc. All types fertilizer equipment from A to Z is on sale here. Welcome to contact us for your customized fertilizer business plan now!