Compound fertilizer granulator is widely used in making powder chemical material into granules. Because the granular compound fertilizer is not easy to agglomerate and convenient to transport and store. Therefore, more and more fertilizer manufacturers use granulating machine in their complex fertilizer production lines. As a professional fertilizer equipment company, YUSHUNXIN designs three types of pellet making machine for your choice. They are disc granulator, rotary drum granulating machine and double roller extrusion pelletizer. They employ different granulation methods to granulate compound fertilizer. If you are interested in them or want to know more, please contact us immediately.

Main Parameters

- Capacity:1-20 t/h

- Granule size: 1-10 mm

- Granulation rate: 90%-97%

- Type:disc granulator, rotary drum granulating machine, double roller extrusion pelletizer

- Equipment Material: Carbon steel Q235, alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Application: NPK, industrial salt, mine rocks, lime, etc

Why so many fertilizer suppliers choose to make compound fertilizer into pellets ?

Generally speaking, compound fertilizer is processed into two forms: powdery and granules. But compared to powder compound fertilizer, granular complex fertilizer is more popular with farmers and fertilizer manufacturers. Why?

For one thing, powder compound fertilizer is easy to layer and agglomerate during storage and transportation. So you need to mix and pulverize it again before using. But after granulating, the contact area between the granular compound fertilizer and the air will become smaller. So it has a lower possibility of layering and sticking. You can use it directly.

For another, when you apply powder chemical fertilizer, you will find that a considerable amount of fertilizer will be blown away by the wind, or washed away by rainwater. And without granulation, compound fertilizer will release its nutrients of nitrogen, phosphorus, potassium quickly. It will lead to a low utilization rate of compound fertilizer nutrients. In contrast, granular complex fertilizer is not easy to be blown away and can reduce the release speed.

Which equipment is suitable for chemical fertilizer granulation ?

As mentioned above, there are 3 types of granulating equipment suitable for compound fertilizer making. Disc granulating machine, rotary drum granulator and double roller extrusion pelletizer. They can help you turn powdery complex fertilizer into particles easily. Following is some information about them:

Economical pan granulating machine

If you want to buy a economical granulator for your compound fertilizer making, disc granulator is an excellent choice for you. On the one hand, it has three discharge ports, which are convenient for intermittent compound fertilizer production operations. So it can greatly reduce labor intensity and improve labor efficiency. And it is made of Q235B boiler steel, which is wear-resistant, anti-corrosion. So our pan granulating machine has long service life. On the other hand, its granulating rate can reach more than 93%, which can reduce waste of chemical materials. And compared with other compound fertilizer granulators, it has a favourable price. So it is suitable for those who don’t have enough budget.

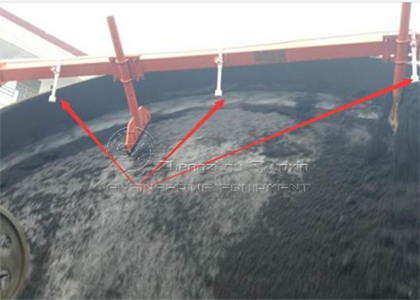

Large scale rotary drum granulator

If you need a pellet making machine for large scale chemical fertilizer production. We recommend you to choose rotary drum granulator. Because it has higher capacity than other granulators and its largest capacity can reach 30 t/h. And whether you plan to manufacturing high, medium or low concentration complex fertilizer. Whether you want to prepare compound fertilizer by hot or cold granulation. Our rotary drum granulating machine can fully meet your needs. Therefore it will be a good partner with your compound fertilizer production.

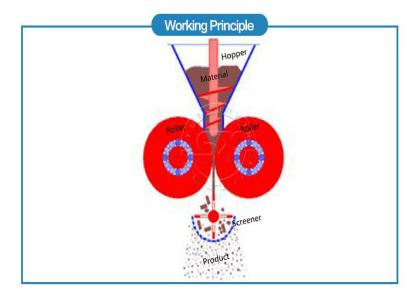

Double roller extrusion pelletizer with no drying

If your chemical material has a low moisture if below 10%, double roller extrusion pelletizer is your best option. Because it makes compound fertilizer into pellets mainly by pressing force. It nearly doesn’t require water. So you don’t need to spend money on subsequent drying and cooling. Therefore, if you want to produce compound fertilizer at a low cost, double roller granulator can also help you a lot.

Different scales compound fertilizer pellet making machines

When you choose a compound fertilizer granulator, capacity is an aspect that you must focus on. And we can provide you with suitable granulating equipment according to your requirements.

If you plan to start a small scale complex fertilizer granulation, which has a capacity below 3 t/h. You can buy any of the above three fertilizer pellet making machines. But if your ideal capacity is between 3 t/h and 6 t/h. Disc granulating machine and rotary drum granulator are more suitable for you. If you need a equipment for large scale compound fertilizer granulation (more than 6 t/h). Only rotary drum pelleting machine can meet your requirements.

Therefore, whether you want to produce chemical fertilizer in a small, medium or large scale. We can provide you with the most suitable pelletizer. If you have any special requirements, please contact us. We also can offer you customization service.

What method you can use to granulate complex fertilizer ?

Do you know what granulation method we usually use in complex fertilizer making? In general, it contains two granulation methods: wet granulation method and dry granulation method.

Wet granulation method

If you want to produce high quality compound fertilizer, wet granulation method is your best choice. It uses liquid as binders to enhance the adhesive force. So your compound fertilizer will be more compact and not easy to pulverize. And it is convenient for transport and storage. In addition, because of water involved, there is less dust pollution during compound making. For this, we recommend pan granulator and rotary drum pelletizer to you. They are both designed with spraying devices.

Dry granulation method

But if your chemical material is sensitive to heat and humidity, you can make complex fertilizer by dry granulation method. It mainly granulates compound raw materials by extrusion, which nearly doesn’t need water. So it also doesn’t require drying by high temperature. Then you can reduce the cost of fertilizer drying and cooling. Therefore, it is an ideal choice for those who want to make complex fertilizer with low cost. In this case, we can provide you with double roller granulator.

What you can do for better compound fertilizer granulation ?

Do you want to make your granulation process more smoothly? Do you want to improve the quality of your compound fertilizer? There are some tips for you.

Make raw materials finer

When you manufacture compound fertilizer, you will find that many raw materials are easy to absorb moisture and stick to each other. And the agglomerated chemical materials will influence the effect of granulation. So we recommend you use finer chemical materials. And the fertilizer crusher will help you a lot. It can grind the material cake into finer powder quickly and easily.

Add bentonite

If you can increase the adhesive force between the materials, they will bond more closely during granulation. So the produced granular compound fertilizer has a higher strength and becomes easier to transport and store. Here, bentonite can fully meet your needs and our fertilizer mixer can blend it with main materials evenly.

Control moisture

The moisture content plays an important role in compound fertilizer granulation. Too high water content will produce complex fertilizer granules with large size and low strength. And too low moisture will make the material not easy to granulate. So you need to control the moisture at a proper level. If you use wet granulation method, you need to keep the moisture content at 20%-40%. But if you use dry granulation method, we recommend you control it to below 10%.

How to buy compound fertilizer granulator at a favourable price ?

When you plan to buy compound fertilizer granulator, price is an item you must pay attention to. But how to buy the machine at a favourable price? There is some advice for your reference:

Find a reliable compound fertilizer granulator manufacturer

SX is a leading supplier for complex fertilizer granulator in China. It has mature technology in fertilizer equipment manufacturing. So the cost of the granulator manufacturing will decrease. So you can buy the compound fertilizer pelletizer with an ideal price.

Buy compound fertilizer granulator from source factory

Compared with distributor, source factory can provide you compound fertilizer granulator with a more favourable price. Because there is no broker in the whole business, you don’t need to pay extra charge. For this SX can fully meet your needs.

Choose compound fertilizer granulator according to your needs

The price of compound fertilizer pelletizer will change according to its type and capacity. If you choose a not suitable machine, it may take you more money. SX can offer you free project design according to your actual conditions. You can make compound fertilizer particles in an economical way.