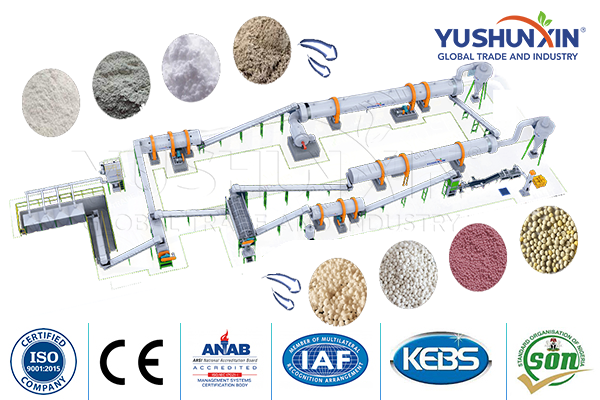

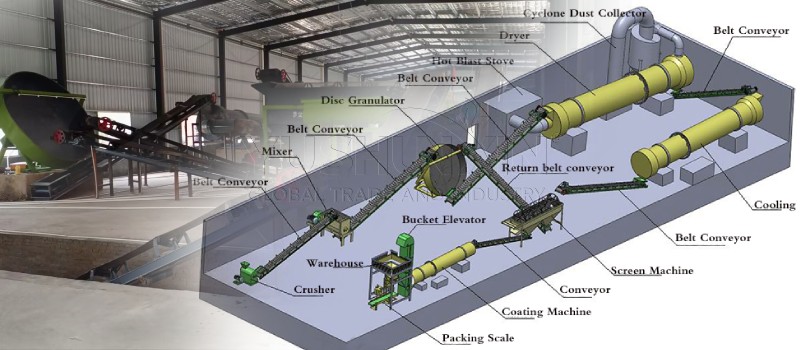

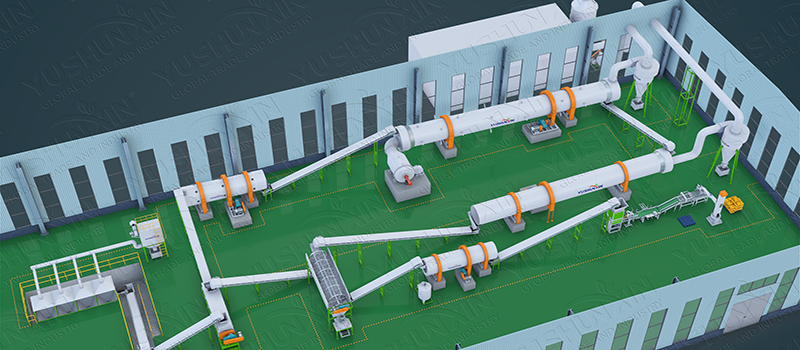

Compound fertilizer production line, as the name implies, is a production line widely used in making chemical ferCompound fertilizer production line, as the name implies, is a production line widely used in making chemical fertilizer. It usually contains equipment of batching, crushing, mixing, granulation, drying, cooling, coating, bagging and accessories. They can produce complex fertilizers with different concentrations and types. Such as NPK compound fertilizer granules making and blended NPK fertilizer production. Moreover, according to need, YUSHUNXIN will offer you customized solutions and machine. Including npk blue granular compound fertilizer factory layout, phosphate rock fertilizer production line, etc.

Main Parameters

- Capcity: 1-20 t/h

- Equipment Material: Carbon steel Q235/Alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Chemical material shape: powder or granule

- Types: NPK fertilizer making, bulk blending fertilizer production, SSP fertilizer manufacturing, etc

- Application: Urea, ammonium chloride, superphosphate,potassium chloride, etc

How to produce 15-15-15 NPK compound fertilizer?

What are the raw materials contained in compound fertilizer manufacturing?

In general, to process compound fertilizers, your main material must contains two or more nutrient elements in nitrogen, phosphorus and potassium. Then, what kind of material contains these elements? There are some for your reference.

Nitrogen is mainly responsible for promoting the growth of branches and leaves. Because it can improve the ability of plants to absorb nutrients. If you want to make compound fertilizer with rich nitrogen element. You can use urea, ammonium chloride, ammonium sulfate, ammonium nitrate and calcium nitrate as materials.

Phosphate plays an important role in blooming and fruiting. If you want to increase its content when preparing compound fertilizer. Monoammonium phosphate (MAP), diammonium phosphate (DAP), triple superphosphate (TSP) and superphosphate (SSP) are excellent options for you.

Potassium is essential to promote the development of rhizomes. And improving the ability of crops to adapt to temperature changes and resist pests and diseases. Then potassium chloride (MOP), potassium sulfate (SOP), potassium carbonate and plant ash is the key to the production of complex fertilizer with potassium.

There are various materials for making compound fertilizers. You can choose according to your needs. Like the complex fertilizer making processes. For different processes, you need to prepare materials with different shapes. Powder or granule?

2 best-selling compound fertilizer production lines in YUSHUNXIN

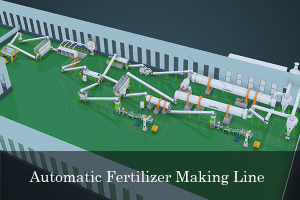

In order to meet the needs of producing compound fertilizers, our engineers design a variety of chemical fertilizer making systems. Among them, the following 2 kinds of compound fertilizer production lines are our hot sale products. They is designed for high profitable compound fertilizer business and fast return complex fertilizer plant setup respectively. For materials, one uses powder and the another adopts pellets.

NPK fertilizer Granulation line for sale

If you are prone to make granular compound fertilizer, we will recommend NPK fertilizer production line to you. As the above process, it will produce NPK compound fertilizer granules from powder for you. In addition, we can offer you customized compound fertilizer making plan according to your needs, like capacity.

- When you plan to make 1-6 tons chemical fertilizer granules per hour, the disc pellet making line is the best choice. Economical price and over 93% granulation rate.

- But if you want to enlarge the complex fertilizer plant scale, you can replace pan granulator with rotary drum pelletizer, which has a large output of 1-30 t/h. So it can fully meet your needs, whether you plan to build a small, medium or large compound fertilizer plant.

Inquiry the NPK compound fertilizer granulation line!

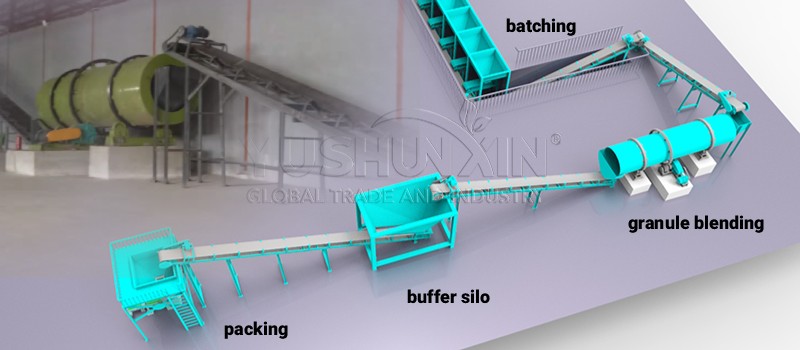

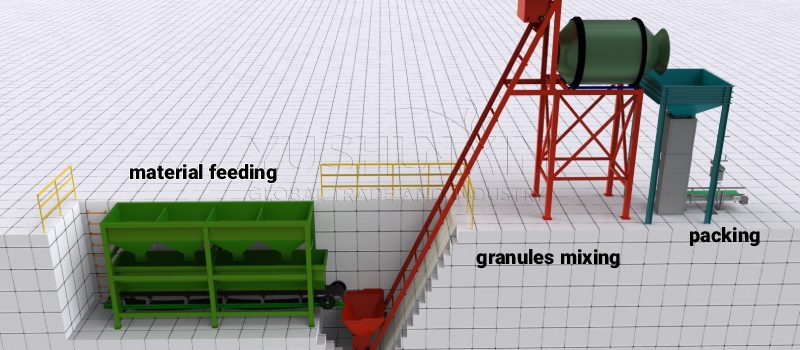

BB fertilizer production line for sale

If you plan to make granular compound fertilizer, but your budget is not enough. You can choose this BB fertilizer production line, which is also known as bulk blending fertilizer making line. You just need to feed several single fertilizers or compound fertilizers to the batching bins. Then after the mixer blends them evenly, you can package the fertilizer. There is only a mechanical force, but no chemical reaction occurs. So bulk blending fertilizer production line has fewer process steps and greatly reduces your production cost. It consists of four kinds of fertilizer equipment. Including batching machine, conveyor, mixer and packing machine. You only need to preapre $10,000-$90,000 budget for NPK fertilizer making in 1-20 T/H capacity.

Get the BB fertilizer making line immediately!

How to make the raw materials into the complex fertilizer you need?

If you want to turn raw material into high-quality fertilizer, you need to process it multiple times. As a professional fertilizer equipment manufacturer, Shunxin can provide you with suitable fertilizer equipment for every procedure. The following is the most complete production procedure for compound fertilizers.

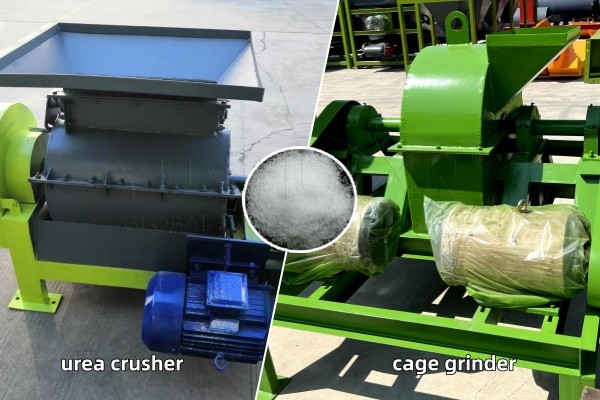

Crushing

Before producing compound fertilizer, you need to make all materials into powder. Because it is convenient for subsequent batching and mixing. So the fertilizer crusher plays an important role in high quality chemical fertilizer production. Cage shredder and chain crusher are suitable for grinding compound fertilizer materials.

Batching

Compound fertilizer is especially produced to supplement the nutrients lacking in plant growth. So you need making it in a certain proportion. Batching is the process to adjust the proportion. During this process, there are static batching machine and dynamic automatic batching equipment for your choice. They have a high degree of automation and can greatly save your time and production cost.

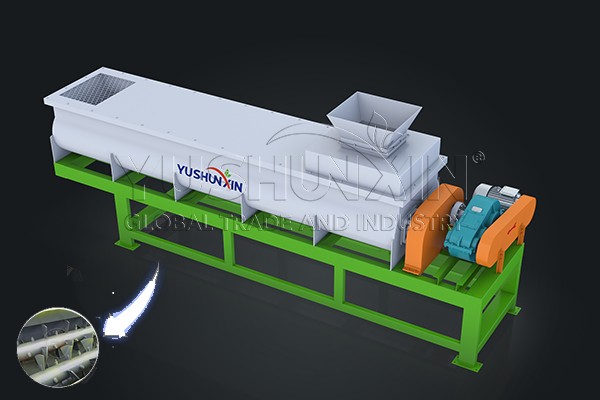

Mixing

Then you need to fully mix the materials. It is the key step to making uniform compound fertilizer. For this, we recommend you choose horizontal mixer or disc mixer. The former can hlpe you mixing different chemical materials evenly effectively and the latter can help you reduce the cost of compound fertilizer making.

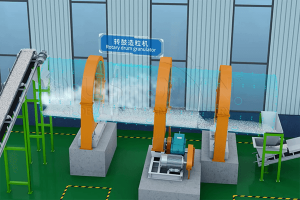

Granulating

If you want to further improve compound fertilizer, turning it into granules is an excellent choice. After granulating, contact area between fertilizers will become smaller, which makes it not easy to stick. So it is convenient for storage and transport. Among our chemical fertilizer granulators, pan granulator, rotary drum pelletizer are more suitable for using wet granulation method. And the double roller granulation is an ideal choice, if you want to use the dry granulation method.

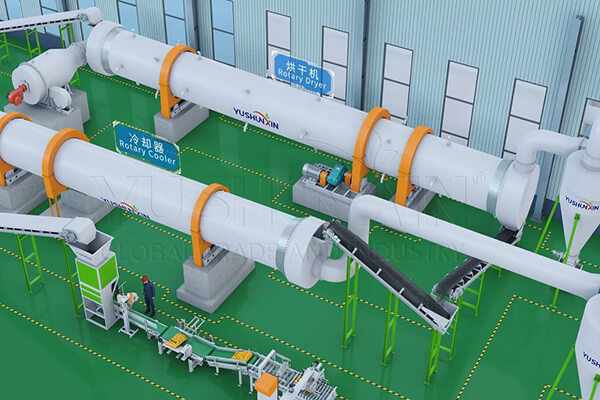

Drying and cooling

Excessive moisture content is not conducive to the storage and use of fertilizers. If the moisture content of fertilizer is more than 14%, the drying process is inevitable. Then after drying, cooling can remove the water from the pellets surface, and lower the temperature.

Screening

During this process, you need to differentiate between qualified and unqualified fertilizers. Then convey the qualified fertilizer to the next procedure, and the unqualified to re-granulate. Rotary screening machine can help you complete the task perfectly.

Coating

It will form a protective film on the surface of the chemical fertilizer. The protective film can isolate the air, which can make granules become easy to stick again. If you want to add a protective film to your chemical pellets, you can buy our drum coating equipment.

Packaging

Packaging is the last procedure of the whole compound fertilizer production line. It is dispensable if you make fertilizer for your own use. But if you want to sell it to others, it can improve the competitiveness of your fertilizer products.

How to start a compound fertilizer business?

As compound fertilizer demand grows, more and more people or companies switch to producing chemical fertilizer. Do you know what need to consider if you want to start a compound fertilizer business? There are some tips for your reference:

Make a compound fertilizer making budget plan

It is based on your survey and research on the compound fertilizer industry. This plan needs to include your total budget, as well as your budget for each project. Such as factory land, fertilizer equipment, materials, etc

Decide your chemcial materials and find a stable supplier

Only after determining the type of raw materials, you can choose the appropriate equipment. With a stable source of raw materials, you can produce fertilizers consistently. It ensures you have enough products to sell.

Choose a place to build the workshop for compound fertilizer factory

It should be far away from the living and working area of the population. Because there will be some pollution in the process of producing compound fertilizer. You need to avoid letting this pollution affect denizens’ lives. And the workshop needs to be located in an easily accessible place. It is beneficial for the sale and transportation of compound fertilizers.

Select a reliable complex fertilizer equipment manufacturer

It can not only provide you with high quality compound fertilizer equipment, but also offer you a lot of helpful advice. SX has 20 years of experience in compound fertilizer equipment production. It is an optimal choice for you.

Other articles about compound fertilizer making

In addition, if you want to learn more about organic fertilizer making, we also can offer you the best solutions. Welcome to contact us to start your compound & organic fertilizer making business successfully.