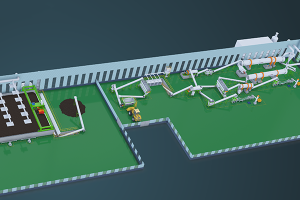

Australia is one of the countries in the world that uses liquid fertilizers on a large scale. Then how to prepare organic liquid fertilizer? On 25th November 2023, a customer from Australia inquired about it. The client planned to setup a plant which can make 10 tons of liquid fertilizer per day from poultry manure, charcoal, sludge, etc. After communication in detail, the Australian customer chose our quality organic liquid fertilizer production system, which contains solid-liquid separator, filters, liquid fertilizer reactor and liquid filling machine. The following are the specific details of this case:

Main Paramters

How to make poultry manure into liquid fertilizer 10 ton/day?

This Australian client told us that the raw materials for preparing organic liquid fertilizer include poultry manure, eggshells, charcoal, chicken feathers, slaughterhouse liquid sludge, macro and micro elements, etc. Are these enough? Of course. With 3 steps, you can turn poultry manure into liquid fertilizer successfully.

Separating suitable liquid raw material

As mentioned above, the material for liquid organic fertilizer manufacturing is a mixture of solid and liquid. For quality liquid fertilizer making, it is necessary to extract liquid from poultry manure mixture first. Here, screw type dehydrator is an ideal choice. It is suitable for small scale 10 tons of manure separation a day and the liquid collection rate can reach 90%.

Filtering impurities from liquid fertilizer

Then you need to further filter poultry manure liquid, which is greatly beneficial for improving final liquid organic fertilizer quality. In this process, SX can offer you liquid filter machine with UV sterilization system. As the name suggests, it will further filter liquid fertilizer to remove small waste particles and kill harmful bacteria in poultry manure liquid by UV.

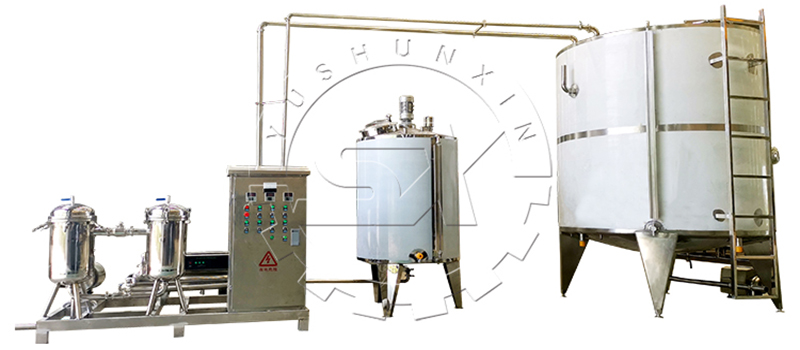

Processing with liquid fertilizer reactor

Finally, the most important step for preparing organic liquid fertilizer – liquid fertilizer fermentation. Under the environment of no oxygen and high temperature, organic matter in poultry poop liquid will decompose into absorbable small molecule substances. Is there suitable machine for the anaerobic fermentation of liquid fertilizer? Our liquid fertilizer reactor tank is an excellent option. For one thing, it uses 304 stainless steel as liquid fertilizer equipment material. So it can withstand the corrosion from liquid fertilizer making. For another, the machine has an inside mixing shaft design. Which can blend liquid to make materials ferment faster.

Get your liquid fertilizer making system now!

What is the heating source of liquid organic fertilizer production?

Then considering the cost of liquid organic fertilizer making, the client from Australia asked us about the heating sources of the liquid manure handling system. What is the heating source of liquid organic fertilizer machines? Gas or oil? Both are no problems. We can adjust the machine design according to your requirements. In addition, our liquid fertilizer machines adopt advanced motors, which means lower energy consumption.

Is there liquid filling machine for 1,5 and 20 lite packages?

At the end, this Australian liquid fertilizer manufacturer focused on the packaging system of liquid fertilizer. There is a plan of 1, 5 and 20 lite packages. Then also in half liter volume in spray packaging. Our automatic liquid filling machine can fully meet your requirements in packaging. There are automatic filling, covering, labeling systems for your choice. These can help you finish the packaging of organic liquid fertilizer production in a short time.

The above are details about our communication with the customer about how to prepare organic liquid fertilizer in Australia. In addition, if you need other liquid fertilizer machines or want to make organic fertilizer from solid animal manure, we can also provide you with the best solution and equipment.