Roller extrusion granulation line is widely used in compound fertilizer production. It can turn powder chemical material into granules at a lower cost. Because it adopts dry granulation method, which makes compound fertilizer particles only by physical extrusion force. And there is nearly no water involved in complex fertilizer making process. So you don’t need to spend on fertilizer pellets drying and cooling. In addition, it also has characteristics of less energy consumption, high granulation rate, easy operation, etc. This is the reason why more and more fertilizer choose double roller granulation line for their fertilizer plant. Moreover, YUSHUNXIN can provide you with roller extrusion granulation lines with different capacities and design layout according to your actual conditions. If you are interested in it, you can contact us at any time.

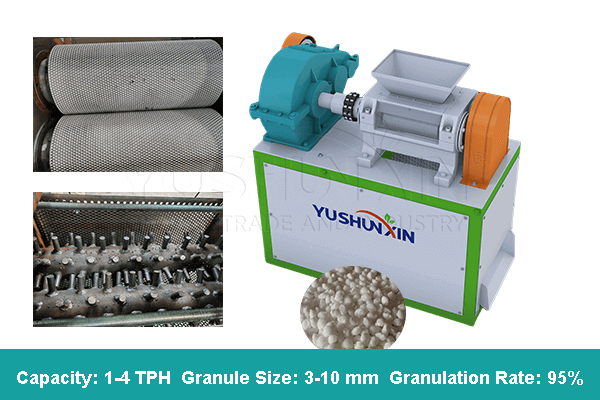

Main Parameters

- Capacity: 1-20 T/H

- Granulation rate: 95%

- Granule Size: 3-10 mm

- Equipment Material: Q235 carbon steel, stainless steel alloy (cuatomized)

- Price: $50,000-$300,000

- Application: NPK, Ammonium sulfate, phosphate rock powder, black carbon, snow melting agent, compost, etc.

When to buy a double roller extrusion granulation line for your fertilizer making project?

If you want to choose a right fertilizer granulation line, you need to focus on the aspects of material, granulated fertilizer and costs. Then, when the double roller granulation system is the best option?

Dry powder granulation with less than 20% moisture

If you plan to make fertilizer granules from drying powder of the moisture less than 20%, a roller press pellet making system fits perfectly. Through dry granulation method of physical pressing, it can process dry powder into granules faster and at a lower cost. Because, there is no needs of liquid adding for cohesion enhance and extra drying units for moisture reduction.

Hard fertilizer granule production with 95% granulation rate

At the same time, the roller extrusion granulation system also can fully meet your requirements of quality fertilizer pellets making. For the hardness of the granulated fertilizer particles, it can improve it to 15-20N. At the same time, the granulation rate of your powder pelletizing project with up to 95%.

Economical fertilizer pellets making

As mentioned above, it is an more affordable fertilizer granule making project for you. for a 1-20 TPH fertilizer granulation plant setup, you only need to prepare $50,000-$300,000. For standard configuration, you only need to buy batching machine, mixer, double roller granulators, screener, packaging machine and belt conveyors for it.

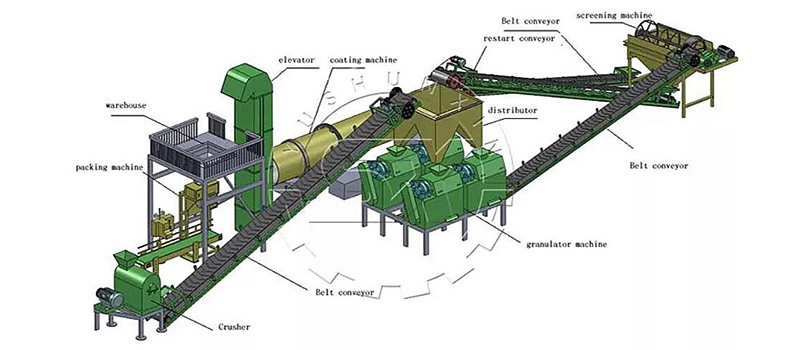

How does double roller pressing system work to process fertilizer pellets?

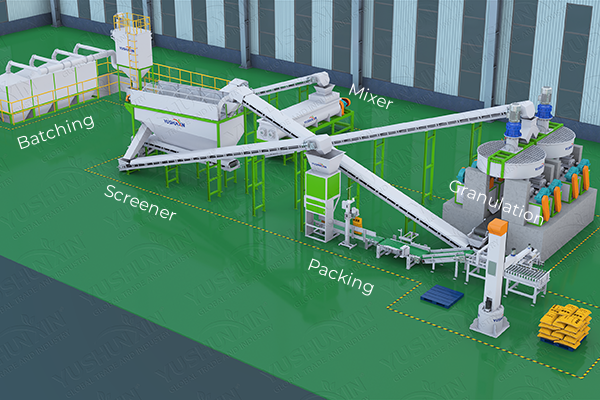

Generally, only by 5 steps, the double roller granulation system will process dry powder into commercial fertilizer granules.

Batching materials with required formula

To produce commercial fertilizer granules with required proportion, the industrial batching machine can help you a lot. With PLC control system and electronic belt scale or nuclear scale, it will feed materials for fertilizer granulation with high precision – 2‰.

Here, to fully meet your requirements of compress fertilizer pellets making with multiple and single material, in a large and small scale, YUSHUNXIN specially design 3 types fertilizer batching machines for you. They are dynamic batching machine with various materials feeding simultaneously, static batching equipment with one by one feeding, and loader feeder for fertilizer granulation with single material.

Mixing powder materials evenly

Then, if you make granular fertilizer from multiple materials, such as the NPK fertilizer granulation, the mixing is necessary to ensure the nutrient balance.

For this, YUSHUNXIN fertilizer mixer can help you blend powder evenly in a large scale quickly because of advanced design. For example, the double shaft horizontal mixer, which is designed with two counter-rotating stirring shafts, process fertilizer materials by continuously lift, toss, and shear to disperse. So, you can prepare fine powder mixture material with balance nutrients for fertilizer pellet making.

Roller granulator work to make compress fertilizer pellets

This is the most important step in fertilizer roller extrusion granulation line. In this process, the mixed material will be granulated into flat ball cakes under the action of rollers extrusion force. Next, there are stirring shaft and sieve to disperse compress cake into fertilizer pellets. In general, there are double roller granulators with 1-4 TPH capacities for your choice.

Screening granulated fertilizer granules

Then, to prepare fertilizer pellets with uniform size, you need to screen granulated fertilizer particles quickly. Here, a rotary sieving machine is an idea choice.

This machine can screen out granular fertilizer with required size in a short time. But, how to dispose of the fertilizer particles with small and large size? Only need to add a chain crusher near the fertilizer pellet sceener. This will grind the left fertilizer granules into powder and you can return them to double roller extrusion equipment to granulate again.

Packaging finished granular fertilizer into 20-50 kg/bag

Finally, to transport and sell granulated fertilizer to farmers, it is advisable to packaging them into required bags.

For industrial fertilizer granule making, YUSHUNXIN design both single and bucket granules bagging machines.They will fully meet your requirements of 20-50 kg/bag fertilizer packing. The difference is that the latter has a larger capacity than the former. What’s more, we can also offer you fully automatic fertilizer packaging scale for your fertilizer roller extrusion granulation line.

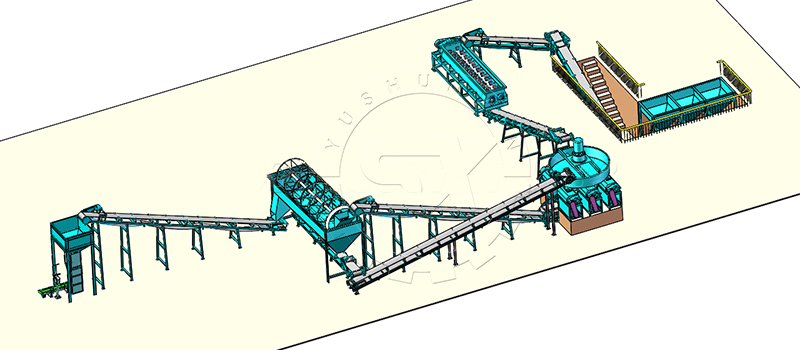

1-20 T/H roller extrusion pelleting lines in YUSHUNXIN

The capacity of double roller granulation line must be an item most fertilizer manufacturers pay attention to. Then what is the capacity of this compound fertilizer making line? The answer is that it can produce fertilizer not only in a small scale but also in a large scale. Different capacity requirements have different project designs. Generally speaking, it can be divided into two cases.

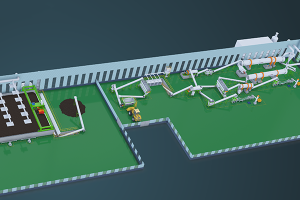

1-3t/h small scale double roller granulation line

If you plan to start a small scale compound fertilizer plant, we can provide you with 1-3 t/h double roller granulation line. This fertilizer making line usually contains a static batching machine, a SXPJ-1600 disc mixing machine, a double roller pressing pelletizer, a granular fertilizer screener, an automatic packaging machine and belt conveyors. In addition, they are all controlled by an automatic electrical control system. Only 2-3 workers, you can keep the whole complex fertilizer granulation line running. And the smallest fertilizer roller extrusion line only needs 800㎡ for installation.

Larger scale roller pellet making line

But if you want to enlarge your complex fertilizer making scale, we also can offer you a suitable design of fertilizer roller extrusion granulation line. Because of the requirement of large output, you need to choose fertilizer processing machines with a large capacity. In this case, we recommend you choose dynamic automatic batching machine for batching and double shafts horizontal mixer for chemical materials blending. Then the largest capacity of double roller pelleting machine is 3 t/h, how to enlarge the granulation output? You can choose to increase the number of roller granulators. If you equip your fertilizer manufacturing line with four roller granulating machines. Then keep the double roller pelleting line running two shifts a day and 10 hours per shift. It can produce about 70,000 tons of granular compound fertilizer per year.

Why so many fertilizer suppliers choose roller granulation line for their fertilizer plants?

In recent years, more and more people choose roller extrusion granulation line for compound fertilizer making. Why?

How to buy fertilizer roller granulation line at a favourable price?

Price of this roller pressing granulation line also must be an item you focus on. And a complete SX double roller granulation line will cost$25,000-$40,000. Then how to buy it in an economical way? There are three tips for your reference.

Finding a leading fertilizer equipment manufacturer

General speaking, a leading fertilizer equipment supplier has mature technology and rich experience in fertilizer equipment manufacturing. So it can produce the equipment of the roller granulation line at a lower cost. Thereby it can provide you with high quality fertilizer machines at a lower price.

Looking for a source factory of fertilizer machine production

It is advisable to buy fertilizer machine you need from the source factory rather than the distributor. SX is a source factory of fertilizer equipment. If you choose to buy double roller pelleting line from it, we We guarantee you don’t need to pay any extra charge.

Designing a reasonable layout for your compound fertilizer plant

The price of roller pressing granulation line usually varies according to its configuration. So a reasonable project design can help you set up fertilizer plant in an economical way. Here, SX can design project fro you out of charge according to your budget, factory space, capacity, etc.