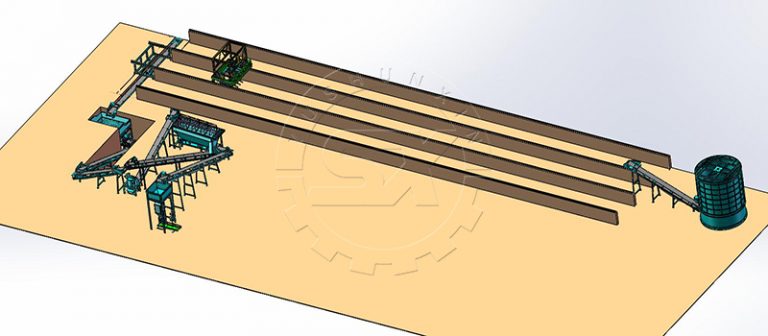

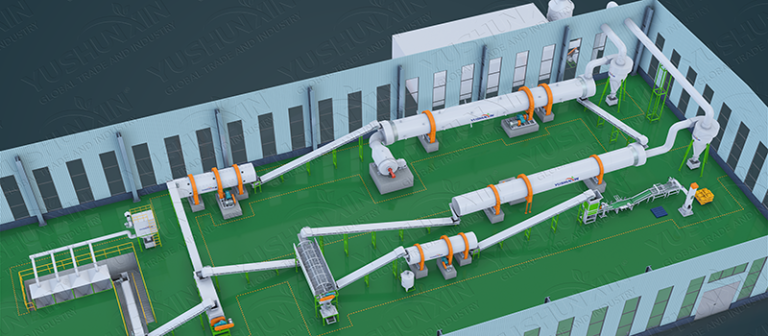

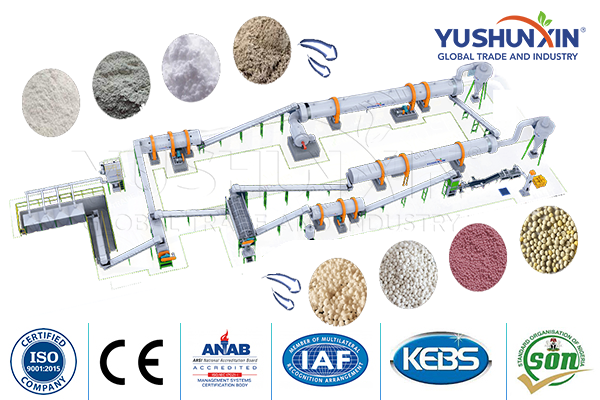

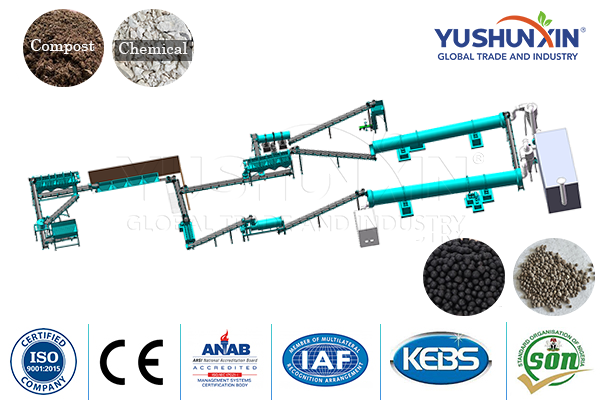

Fertilizer production line is a complete process to make various fertilizers. It contains the fertilizer equipment from material feeding to finished fertilizer packing. Here, as a professional fertilizer equipment manufacturer, YUSHUNXIN has various fertilizer manufacturing line on sale for your choice. Including organic fertilizer making plans, compound fertilizer making line, fertilizer granulation line, etc. In addition, if you want to know about the cost of the fertilizer making line, there is also answer for you.

Main Parameters

- Capacity:1-20 T/H

- Types: Organic & Compound fertilizer making

- Final Shape: Powder & Granules & Liquid

- Cost: $35,000-$500,000

- Application Material: Animal manure, straw, mushroom waste, biogas waste, chemical NPK, mineral waste, etc

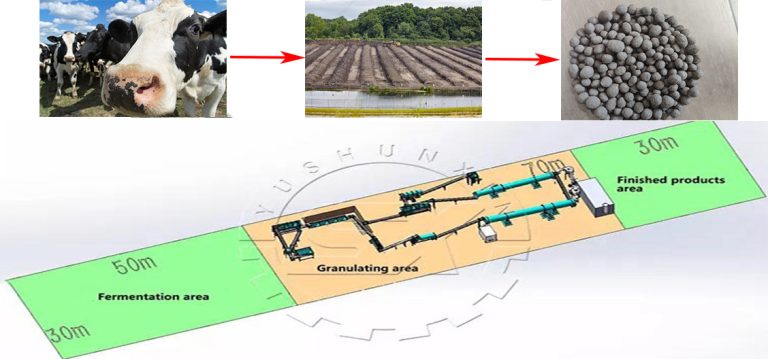

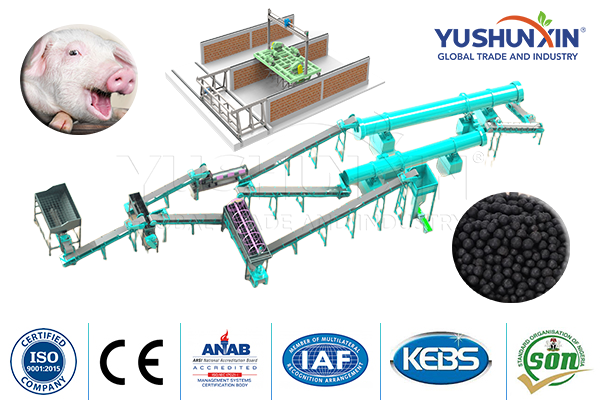

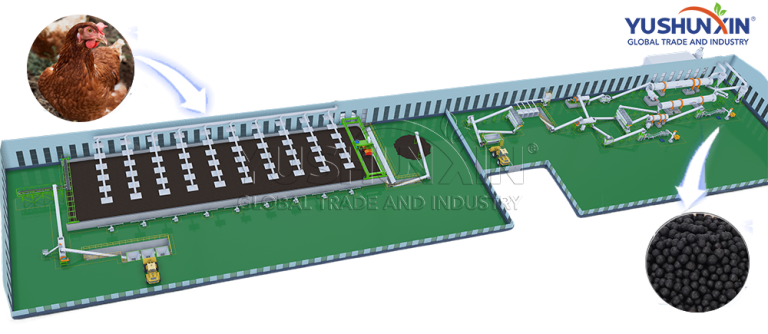

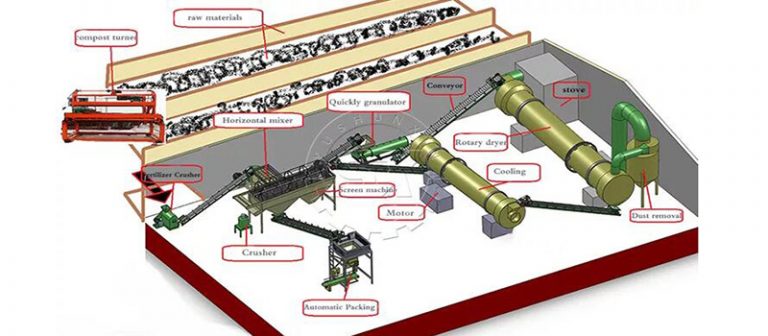

What types of organic fertilizer making lines are on sale?

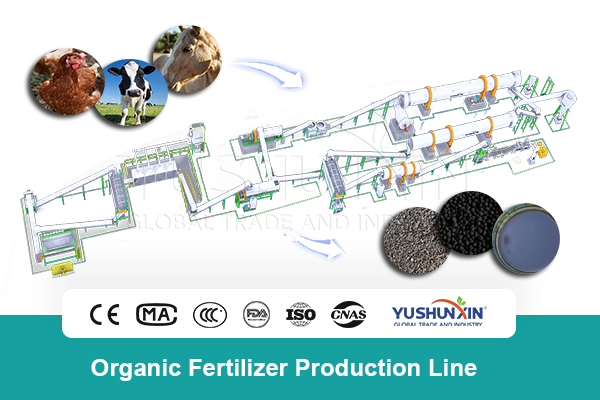

In general, organic fertilizer production line is designed to dispose of the most common organic waste into fertilizer. Such as cow dung, chicken poop, pig waste, goat manure, biogas residue, filter mud, straw, rice hull, wood waste, etc. According to your materials, we especially design customized organic fertilizer making plan for you as follows:

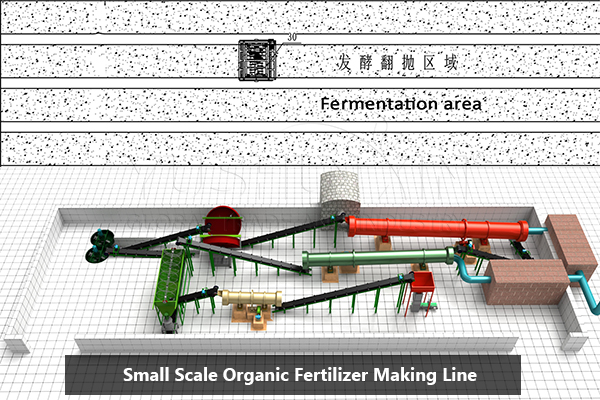

Here, you can choose to make organic waste into powder organic fertilizer or granular organic fertilizer. In addition, in the terms of capacity, there are both small scale organic fertilizer production plan and large scale organic waste fertilizer making system.

Get Your organic fertilizer making line immediately!

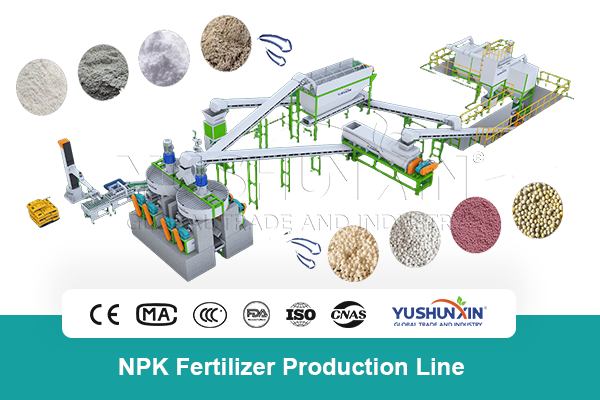

Top 2 compound fertilizer production line for sale

Compound fertilizer production line, as the name implies, is a production line widely used in making chemical fertilizer. It can produce complex fertilizers with different concentrations and types. You can mix urea, ammonium chloride, monoammonium phosphate (MAP), diammonium phosphate (DAP), potassium chloride (MOP), potassium sulfate (SOP), etc and use as materials. Then the produced fertilizer can provide richer nutrient elements in nitrogen, phosphorus and potassium for crops and plants. Foe this, there are 2 types chemical fertilizer making lines for you.

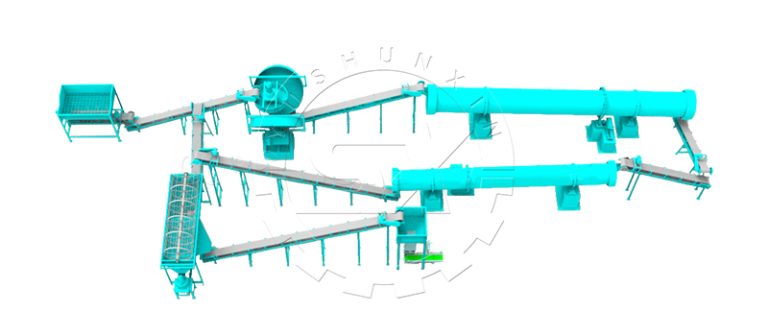

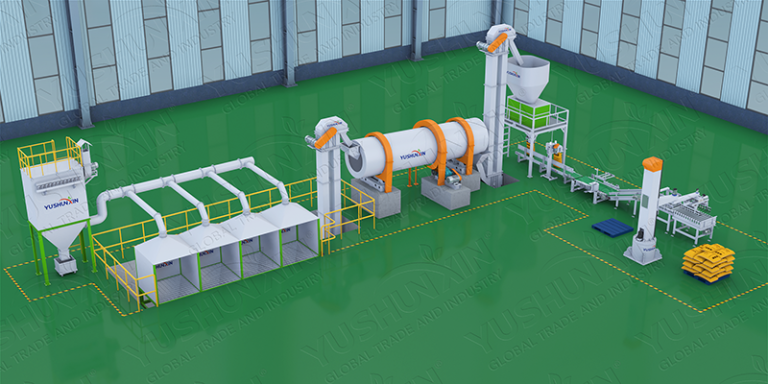

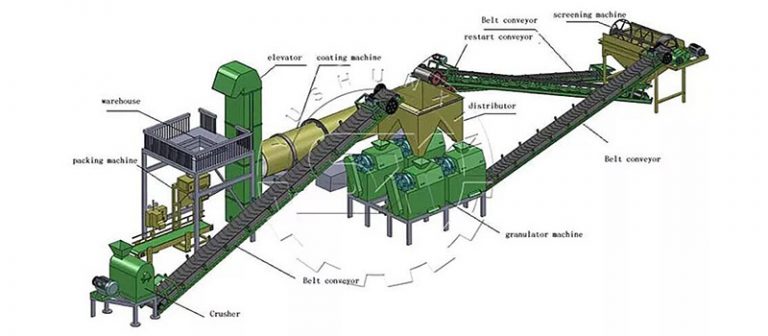

Compound fertilizer granulation line

Here, it is designed to turn NPK powder into compound fertilizer granules. This complex fertilizer production process usually contians batching machine to adjust materials proportion and mixer for blending evenly. granulator for making powder into pellets. Then the dryer, cooler, coater and packing machine in subsequent steps. This is an ideal solution for NPK fertilizer production. Moreover, if you use make Phosphate rock fertilizer, there are also customized fertilizer business plan for you

BB fertilizer preparation line

If you need a compound fertilizer making line with low cost, you can choose BB fertilizer production line. It uses granular fertilizer as materials. It will mix several single fertilizers or compound fertilizers according to a certain proportion. Only several steps, you can get high quality bulk blending fertilizer. It has characters of granule uniformity, less water, granule intensity moderate, no agglomeration, easy to use and low cost. If you want to know more about it, you can contact us for details.

Just tell us what material you want to use for fertilizer making and what production capacity you want to get from the fertilizer making production line. Then, we can provide customization service for you to meet your needs.

Inquiry about compound fertilizer making system now!

How to choose a right solution for your fertilizer granulation plant?

As mentioned above, making fertilizer into granules is popular with both organic and compound fertilizer manufacturers. But how to choose a right solution for fertilizer pellet making? The answer is simple.

Small scale fertilizer granulation line

For small scale fertilizer granulation plant, disc pelleting line is the best choice. For 1-6 t/h output, it makes fertilizer granulation conversion rate increase to more than 93%. In addition, it can fully meet your 1-8 mm size rounded fertilizer particles making.

Large scale fertilizer pellet production plan

If you want to buy a fertilizer granulating line with large capacity, we recommend you buy a rotary drum granulator system. Its maximum output of granular fertilizer is 30 t/h. Moreover, we especially add it with rubber lining and sticking prevention holes to reduce the erosion from large scale fertilizer granulation.

Economical fertilizer granule making system

Finally, we also design double roller fertilizer granulating plan for you. It is an ideal choice for fertilizer manufacturers who need an economical fertilizer pelleting line or want to prepare granular fertilizer without water. Because of dry granulation method employment, you can reduce the costs on fertilizer dryer and cooler buying.

Can I get fertilizer granulation line design now?

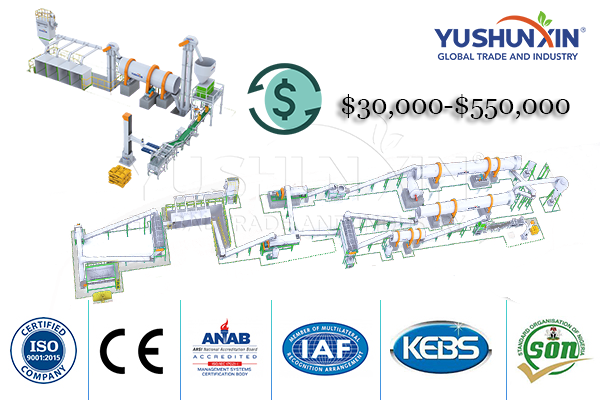

What is the price of a fertilizer production line?

After choosing the fertilizer production line you like, price is an aspect you will definitely pay attention to.

- In general, a complete organic fertilizer making line costs $100,000-$550,000, because of no dehydrator and fertilizer compost machine.

- As for NPK compound fertilizer production investment, you usually need to prepare $80,000-$500,000.

- In addition, when you plan to buy a liquid fertilizer system, with 1-10 m³ capacity, it will costs $40,000-$100,000.

But the detailed cost of a fertilizer making line is depended on the capacity, configuration, equipment types, etc. If you want to get the precise quote for your fertilizer production system, welcome to contact us immediately.

Get precise quote of your own fertilizer making line!

YUSHUNXIN: Quality assured fertilizer machine & production line manufacturer in China

As a professional fertilizer equipment manufacturer with more than 20 years of fertilizer equipment manufacturing experience, our products and services have been well praised by our customers.

On the one hand, we have our own factory and R&D team to provide high quality fertilizer equipment to our customers. Even, we can provide you customized fertilizer production machine according to your requirements and actural conditions.

On the other hand, we can offer you considerate one-stop service. Including question answer, cuatomized fertilizer making plan design, custom clearance, shipment delivery, installation and operation guidance, etc. In addition, we setup YUSHUNXIN overseas branch offices all over the world. Including Algeria, Indonesia, Russia, United States, etc. Welcome to talk about your fertilizer business plan face to face!